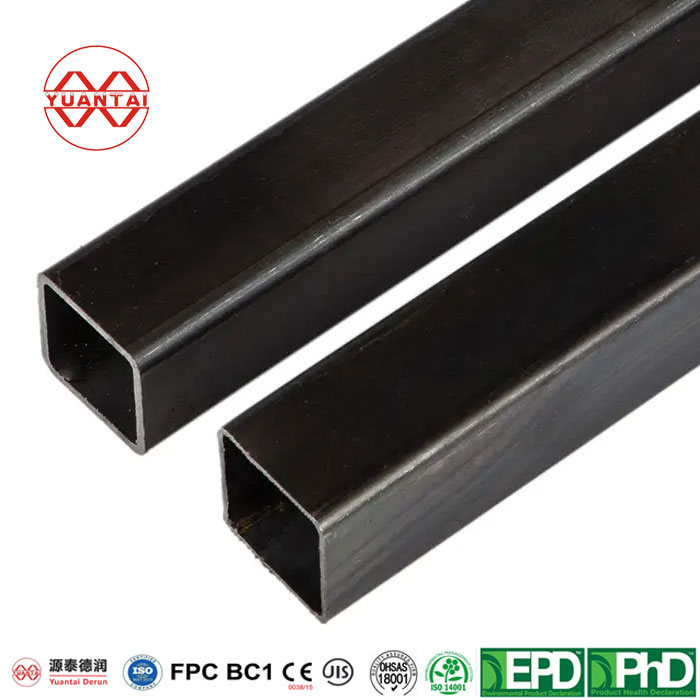

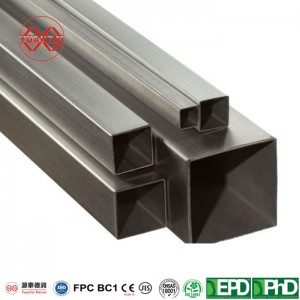

PRODUCT INTRODUCTION

Also known as square and rectangular cold-formed hollow section steel, short for square tube and rectangular tube

PROCESS CLASSIFICATION

Square tubes are divided into hot-rolled seamless square tubes, cold-drawn seamless square tubes, extruded seamless square tubes and welded square tubes according to the production process.

The welded square tube is divided into

1. According to process - electric arc welding square tube, resistance welding square tube (high frequency, low frequency), gas welding square tube, furnace welding square tube

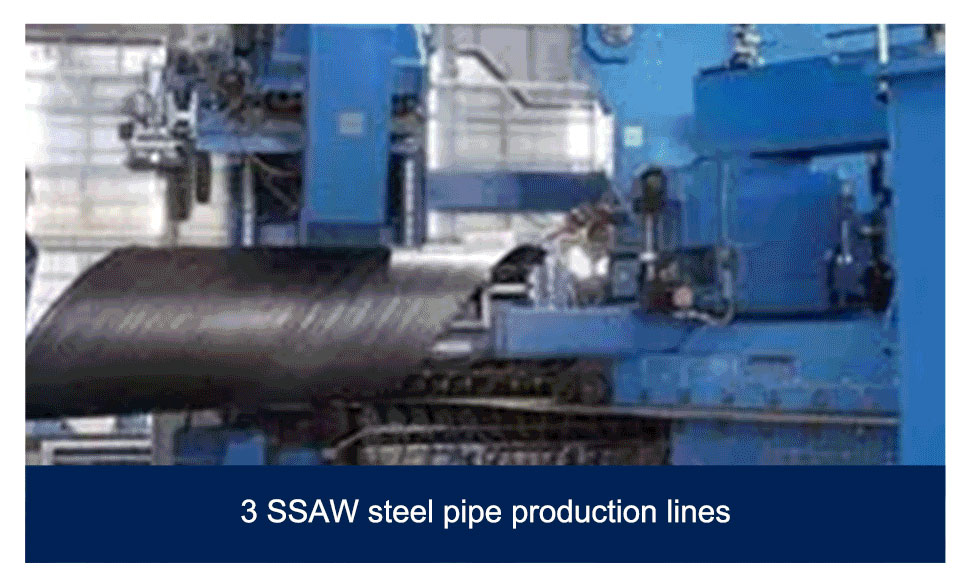

2. It is divided into straight welded square tubes and spiral welded square tubes according to the weld seam.

MATERIAL CLASSIFICATION

Square tubes are divided into plain carbon steel square tubes and low alloy square tubes by material.

1. Ordinary carbon steel is divided into Q195, Q215, Q235, SS400, 20 # steel, 45 # steel, etc.

2. Low alloy steel is divided into Q345, 16Mn, Q390, ST52-3, etc.

PRODUCTION STANDARD CLASSIFICATION

Square tubes are divided into national standard square tubes, Japanese standard square tubes, English standard square tubes, American standard square tubes, European standard square tubes and non-standard square tubes according to production standards.

SECTION SHAPE CLASSIFICATION

Square tubes are classified according to section shape:

1. Simple section square tube: square square tube, rectangular square tube.

2. Square tubes with complex sections: flower-shaped square tubes, open-shaped square tubes, corrugated square tubes, and special-shaped square tubes.

SURFACE TREATMENT CLASSIFICATION

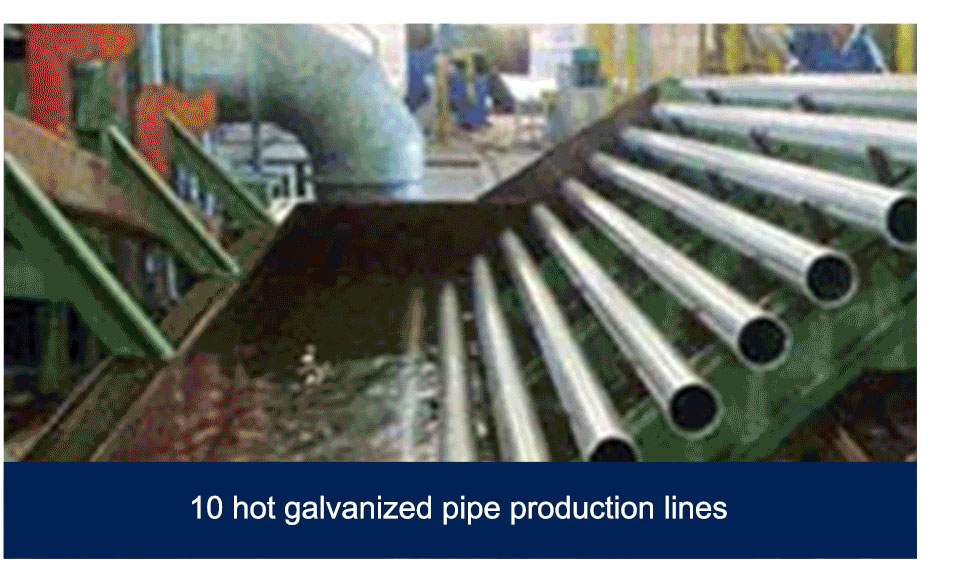

Square tubes are divided into hot-dip galvanized square tubes, electro-galvanized square tubes, oiled square tubes and pickled square tubes according to surface treatment.

WALL THICKNESS CLASSIFICATION

Square tubes are classified by wall thickness: ultra-thick square tubes, thick square tubes and thin square tubes.

EXECUTIVE STANDARDS

GB/T6728-2002, GB/T6725-2002, GBT3094-2000, JG 178-2005, ASTM A500 JIS G3466, EN10210 or technical agreement.

GB/T3094-2000 (national standard) cold-pressed special-shaped rectangular tube

GB/T6728-2002 (national standard) cold-formed hollow section steel for structure

ASTM A500 (American Standard) Cold-formed carbon steel welded rectangular tubes and seamless rectangular tubes with circular and special-shaped sections for structural purposes

EN10219-1-2006 (European Standard) Non-alloy and fine-grained cold-formed welded hollow structural profiles

JIS G 3466 (Japanese standard) Angle rectangular tube for general construction

USE:

Square tubes are used in construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation support, steel structure engineering, power engineering, power plant, agricultural and chemical machinery, and glass curtain wall

Welcome to contact Yuantai Derun, e-mail: sales@ytdrgg.com , real-time connection factory inspection or factory visit!

Specification of square and rectangular hollow sections

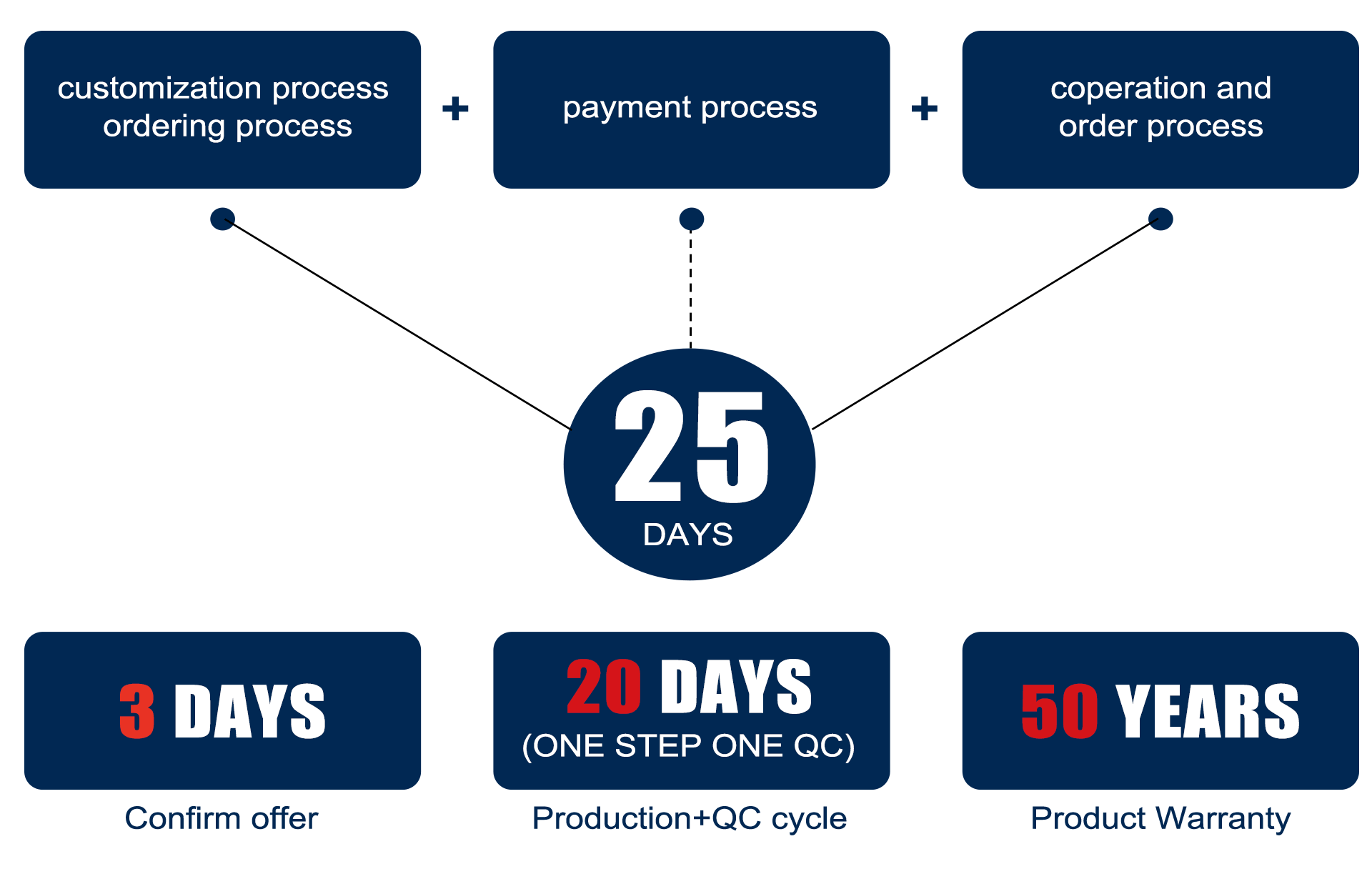

01 DIRECT TRANSACTION

We have been specialized in

producing steel pipes for 21 years,yuantai derun group are the largest

steel hollow section manufacturer in China

- 02 COMPLETE SPECIFICATIONS

OD(outer diameter):10*10-1000*1000MM 10*15-800*1200MM

Wall Thickness:0.5-60mm

Length:0.5-24M or according requirement

Surface treatment:bare oiled painted galvanized

3 CERTIFICATION IS COMPLETE

Tianjin Yuantai derun steel pipe manufacturing group

can produce steel pipe products of world stardard,such as

European standard EN10210,EN10219,

American standard ASTM A500/501,

Japanese standard,JIS G3466

Astralian standard, AS1163

natinal standard GB/T6728,GB/T9711,GB/T3094,GB/T3091

and so on.

04 LARGE INVENTORY

Common specifications perennial inventory of

200000 tons.

Square steel hollow section,

rectangular steel hollow section,

circular steel hollow section

A: We are factory.

A: Generally it is 5-10 days if the goods are in stock. or it is 30 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge with the cost of freight paid by customer.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below

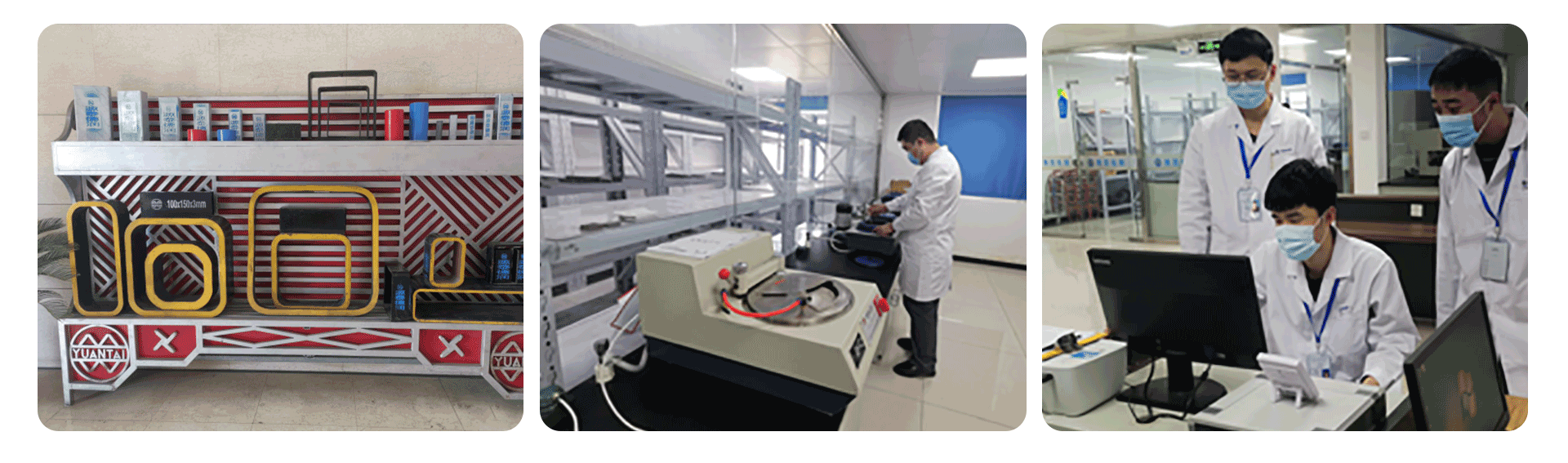

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821