EN10219 Chemical composition, mechanical properties, tolerances and testing standards for straight seam steel pipes

N10219-2006 Cold formed welded hollow steel pipe of non-alloy steel and fine grain structural steel (LSAW longitudinal submerged arc welded steel pipe)

Main materials S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH, S420MH, S420MLH, S460MH, S460MLH, S460NH, S460NLH

1、 Meaning of numbers and letters in EN10219-2006

S: Structural steel

Number after S: zui small yield strength (wall thickness ≤ 16mm)

JR: impact test at normal temperature ≥ 27J

J0: 0 ℃ impact test ≥ 27J

J2: - 20 ℃ impact test ≥ 27J

K2: - 20 ℃ impact test ≥ 40J

N: Normalized or normalized rolling (fine grain steel, impact test must be conducted, temperature zui is lower than - 20 ℃ ≥ 40J)

M: Thermo-mechanical controlled rolling (impact test must be conducted, and the temperature zui is lower than - 20 ℃ ≥ 40J)

50: - 50 ℃ impact test ≥ 27J

H: Hollow profile

2、 Chemical composition (thickness T ≤ 40mm) and mechanical properties

Yuantai Derun can produce EN10219-2006 steel pipes. What are the materials of S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH, S460NH and S460NLH in EN10219-2006

What material is S235JRH, what material is used instead, which company can produce S235JRH straight seam steel pipe

Chemical composition of S235JRH

Carbon ≤ 0.17%, silicon ≤ not required, manganese ≤ 1.40%, phosphorus ≤ 0.04%, sulfur ≤ 0.04%, nitrogen ≤ 0.009%

S235JRH mechanical properties

3mm<wall thickness ≤ 16mm: yield strength ≥ 235MPa, tensile strength ≥ 360-510MPa, elongation ≥ 24%

16mm<wall thickness ≤ 40mm: yield strength ≥ 225MPa, tensile strength ≥ 360-510MPa, elongation ≥ 24%

What is the material of S275J0H, and what material to replace, which company can produce S275J0H straight seam steel pipe

Chemical composition of S275J0H

Carbon ≤ 0.20%, silicon ≤ not required, manganese ≤ 1.50%, phosphorus ≤ 0.035%, sulfur ≤ 0.035%, nitrogen ≤ 0.009%

S275J0H mechanical properties

3mm<wall thickness ≤ 16mm: yield strength ≥ 275MPa, tensile strength ≥ 410-560MPa, elongation ≥ 20%

16mm<wall thickness ≤ 40mm: yield strength ≥ 265MPa, tensile strength ≥ 410-560MPa, elongation ≥ 20%

What material is S275J2H, what material is used instead, which company can produce S275J2H straight seam steel pipe

Chemical composition of S275J2H

Carbon ≤ 0.20%, silicon ≤ not required, manganese ≤ 1.50%, phosphorus ≤ 0.030%, sulfur ≤ 0.030%, nitrogen ≤ not required

S275J2H mechanical properties

3mm<wall thickness ≤ 16mm: yield strength ≥ 275MPa, tensile strength ≥ 410-560MPa, elongation ≥ 20%

16mm<wall thickness ≤ 40mm: yield strength ≥ 265MPa, tensile strength ≥ 410-560MPa, elongation ≥ 20%

What is the material of S355J0H and what material is used to replace it? Which company can produce S355J0H straight seam steel pipe

S355J0H Chemical composition

Carbon ≤ 0.22%, silicon ≤ 0.55%, manganese ≤ 1.60%, phosphorus ≤ 0.035%, sulfur ≤ 0.035%, nitrogen ≤ 0.009%

S355J0H mechanical properties

3mm<wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 470-630MPa, elongation ≥ 20%

16mm<wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 470-630MPa, elongation ≥ 20%

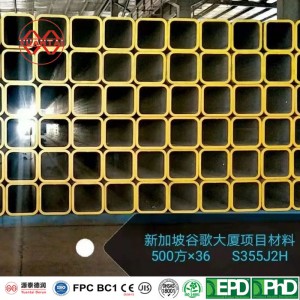

What material is S355J2H, what material is used instead, which company can produce S355J2H straight seam steel pipe

S355J2H chemical composition

Carbon ≤ 0.22%, silicon ≤ 0.55%, manganese ≤ 1.60%, phosphorus ≤ 0.030%, sulfur ≤ 0.030%, nitrogen ≤ not required

S355J2H mechanical properties

3mm<wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 470-630MPa, elongation ≥ 20%

16mm<wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 470-630MPa, elongation ≥ 20%

What is the material of S355K2H, what material is used instead, and which company can produce S355K2H straight seam steel pipe

S355K2H chemical composition

Carbon ≤ 0.22%, silicon ≤ 0.55%, manganese ≤ 1.60%, phosphorus ≤ 0.030%, sulfur ≤ 0.030%, nitrogen ≤ not required

S355K2H mechanical properties

3mm<wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 470-630MPa, elongation ≥ 20%

16mm<wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 470-630MPa, elongation ≥ 20%

What material is S275NH? What material is used instead? Which company can produce S275NH straight seam steel pipe

S275NH chemical composition

Carbon ≤ 0.20%, silicon ≤ 0.40%, manganese ≤ 0.5-1.40%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.05%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.30%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.015%,

S275NH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 275MPa, tensile strength ≥ 370-510MPa, elongation ≥ 24%

16mm<wall thickness ≤ 40mm: yield strength ≥ 265MPa, tensile strength ≥ 370-510MPa, elongation ≥ 24%

What material is S275NLH, what material is used instead, which company can produce S275NLH straight seam steel pipe

S275NLH chemical composition

Carbon ≤ 0.20%, silicon ≤ 0.40%, manganese ≤ 0.5-1.40%, phosphorus ≤ 0.030%, sulfur ≤ 0.025%, niobium ≤ 0.05%, vanadium ≤ 0.05%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.3%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.015%,

S275NLH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 275MPa, tensile strength ≥ 370-510MPa, elongation ≥ 24%

16mm<wall thickness ≤ 40mm: yield strength ≥ 265MPa, tensile strength ≥ 370-510MPa, elongation ≥ 24%

What material is S355NH? What material is used instead? Which company can produce S355NH straight seam steel pipe

S355NH chemical composition

Carbon ≤ 0.20%, silicon ≤ 0.50%, manganese ≤ 0.9-1.65%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.12%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.5%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.015%,

S355NH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 470-630MPa, elongation ≥ 22%

16mm<wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 470-630MPa, elongation ≥ 22%

What material is S355NLH, what material is used to replace it, and which company can produce S355NLH straight seam steel pipe

S355NLH chemical composition

Carbon ≤ 0.18%, silicon ≤ 0.50%, manganese ≤ 0.9-1.65%, phosphorus ≤ 0.030%, sulfur ≤ 0.025%, niobium ≤ 0.05%, vanadium ≤ 0.12%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.5%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.015%,

S355NLH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 470-630MPa, elongation ≥ 22%

16mm<wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 470-630MPa, elongation ≥ 22%

What material is S460NH, what material is used instead, and which company can produce S460NH straight seam steel pipe

S460NH chemical composition

Carbon ≤ 0.20%, silicon ≤ 0.60%, manganese ≤ 1.0-1.70%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.20%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.8%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.025%,

S460NH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 460MPa, tensile strength ≥ 550-720MPa, elongation ≥ 17%

16mm<wall thickness ≤ 40mm: yield strength ≥ 440MPa, tensile strength ≥ 550-720MPa, elongation ≥ 17%

What material is S460NLH, what material is used to replace it, and which company can produce S460NLH straight seam steel pipe

S460NLH chemical composition

Carbon ≤ 0.20%, silicon ≤ 0.60%, manganese ≤ 1.0-1.70%, phosphorus ≤ 0.030%, sulfur ≤ 0.025%, niobium ≤ 0.05%, vanadium ≤ 0.20%,

Aluminum ≥ 0.020%, titanium ≤ 0.03%, chromium ≤ 0.30%, nickel ≤ 0.8%, molybdenum ≤ 0.10%, copper ≤ 0.35%, nitrogen ≤ 0.025%,

S460NLH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 460MPa, tensile strength ≥ 550-720MPa, elongation ≥ 17%

16mm<wall thickness ≤ 40mm: yield strength ≥ 440MPa, tensile strength ≥ 550-720MPa, elongation ≥ 17%

What material is S275MH? What material is used instead? Which company can produce S275MH straight seam steel pipe

S275MH chemical composition

Carbon ≤ 0.13%, silicon ≤ 0.50%, manganese ≤ 1.50%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.08%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.30%, molybdenum ≤ 0.20%, nitrogen ≤ 0.02%,

S275MH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 275MPa, tensile strength ≥ 360-510MPa, elongation ≥ 24%

16mm<wall thickness ≤ 40mm: yield strength ≥ 265MPa, tensile strength ≥ 360-510MPa, elongation ≥ 24%

What material is S275MLH, what material is used instead, and which company can produce S275MLH straight seam steel pipe

S275MLH chemical composition

Carbon ≤ 0.13%, silicon ≤ 0.50%, manganese ≤ 1.50%, phosphorus ≤ 0.030%, sulfur ≤ 0.025%, niobium ≤ 0.05%, vanadium ≤ 0.08%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.30%, molybdenum ≤ 0.20%, nitrogen ≤ 0.02%,

S275MLH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 275MPa, tensile strength ≥ 360-510MPa, elongation ≥ 24%

16mm<wall thickness ≤ 40mm: yield strength ≥ 265MPa, tensile strength ≥ 360-510MPa, elongation ≥ 24%

What material is S355MH? What material is used instead? Which company can produce S355MH straight seam steel pipe

S355MH chemical composition

Carbon ≤ 0.14%, silicon ≤ 0.50%, manganese ≤ 1.50%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.10%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.3%, molybdenum ≤ 0.20%, nitrogen ≤ 0.02%,

S355MH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 450-610MPa, elongation ≥ 22%

16mm<wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 450-610MPa, elongation ≥ 22%

What material is S355MLH, what material is used instead, which company can produce S355MLH straight seam steel pipe

S355MLH chemical composition

Carbon ≤ 0.14%, silicon ≤ 0.50%, manganese ≤ 1.50%, phosphorus ≤ 0.030%, sulfur ≤ 0.025%, niobium ≤ 0.05%, vanadium ≤ 0.10%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.3%, molybdenum ≤ 0.20%, nitrogen ≤ 0.02%,

S355MLH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 355MPa, tensile strength ≥ 450-610MPa, elongation ≥ 22%

16mm<wall thickness ≤ 40mm: yield strength ≥ 345MPa, tensile strength ≥ 450-610MPa, elongation ≥ 22%

What material is S420MH, what material is used instead, which company can produce S420MH straight seam steel pipe

S420MH chemical composition

Carbon ≤ 0.16%, silicon ≤ 0.50%, manganese ≤ 1.70%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.12%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.3%, molybdenum ≤ 0.20%, nitrogen ≤ 0.02%,

S420MH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 420MPa, tensile strength ≥ 500-660MPa, elongation ≥ 19%

16mm<wall thickness ≤ 40mm: yield strength ≥ 400MPa, tensile strength ≥ 500-660MPa, elongation ≥ 19%

What material is S420MLH, what material is used instead, which company can produce S420MLH straight seam steel pipe

S420MLH chemical composition

Carbon ≤ 0.16%, silicon ≤ 0.50%, manganese ≤ 1.70%, phosphorus ≤ 0.030%, sulfur ≤ 0.025%, niobium ≤ 0.05%, vanadium ≤ 0.12%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.3%, molybdenum ≤ 0.20%, nitrogen ≤ 0.02%,

S420MLH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 420MPa, tensile strength ≥ 500-660MPa, elongation ≥ 19%

16mm<wall thickness ≤ 40mm: yield strength ≥ 400MPa, tensile strength ≥ 500-660MPa, elongation ≥ 19%

What material is S460MH? What material is used instead? Which company can produce S460MH straight seam steel pipe

S460MH chemical composition

Carbon ≤ 0.16%, silicon ≤ 0.60%, manganese ≤ 1.70%, phosphorus ≤ 0.035%, sulfur ≤ 0.030%, niobium ≤ 0.05%, vanadium ≤ 0.12%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.3%, molybdenum ≤ 0.20%, nitrogen ≤ 0.025%,

S460MH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 460MPa, tensile strength ≥ 530-720MPa, elongation ≥ 17%

16mm<wall thickness ≤ 40mm: yield strength ≥ 440MPa, tensile strength ≥ 530-720MPa, elongation ≥ 17%

What material is S460MLH, what material is used instead, and which company can produce S460MLH straight seam steel pipe

S460MLH chemical composition

Carbon ≤ 0.16%, silicon ≤ 0.60%, manganese ≤ 1.70%, phosphorus ≤ 0.030%, sulfur ≤ 0.025%, niobium ≤ 0.05%, vanadium ≤ 0.12%,

Aluminum ≥ 0.020%, titanium ≤ 0.05%, nickel ≤ 0.3%, molybdenum ≤ 0.20%, nitrogen ≤ 0.025%,

S460MLH mechanical properties

Wall thickness ≤ 16mm: yield strength ≥ 460MPa, tensile strength ≥ 530-720MPa, elongation ≥ 17%

16mm<wall thickness ≤ 40mm: yield strength ≥ 440MPa, tensile strength ≥ 530-720MPa, elongation ≥ 17%

3、 EN10219-2006 Common tolerance range

Diameter and roundness deviation (for SAWL LSAW steel pipe):

Outer diameter tolerance ≤± 1%, zui small ± 0.5mm, zui large ± 10mm

The outer diameter measurement method is the circumference method, and the measured outer diameter=circumference/circumference

Ovality: 2% when outer diameter/thickness ≤ 100

Tolerance calculation method=(zui large outer diameter - zui small outer diameter)/standard outer diameter X100%

Wall thickness deviation (for SAWL longitudinal submerged arc welded steel pipe):

Outer diameter ≥ 406mm, wall thickness tolerance ≤± 10%, zui larger ± 2mm

Straightness deviation (for SAWL longitudinal submerged arc welded steel pipe, L is the length of steel pipe in mm):

Full-length straightness deviation ≤ 0.002L

Mass deviation: ± 6% (per unit length)

Height tolerance of internal and external welds of submerged arc pipe

Thickness (T) ≤ 14.2zui Large weld height 3.5mm

Thickness (T) > 14.2zui Large weld height 4.8mm

Length tolerance:

Any length: 4000-16000mm, single floating range 2000mm, 10% of the supplied products can be lower than the zui small value specified in the order, but not lower than 75% of the zui small value

Approximate length: tolerance range is 0 to+50mm when ≥ 4000mm

Length:

The tolerance range is 0 to 5mm when the length is less than 6000 mm

Tolerance range 0 to 15mm when 6000mm ≤ length ≤ 10000mm

Tolerance 0 to 5mm+1mm/m when length>10000mm

4、 Our NDT test:

Radiographic and Ultrasonic Testing (RT&UT)

Radiography (RT): 100% steel pipe inspection

Ultrasonic (UT): 100% steel pipe inspection

The water pressure shall be in accordance with the standard or negotiated by both parties

A few words from Yuantai Derun Steel Group

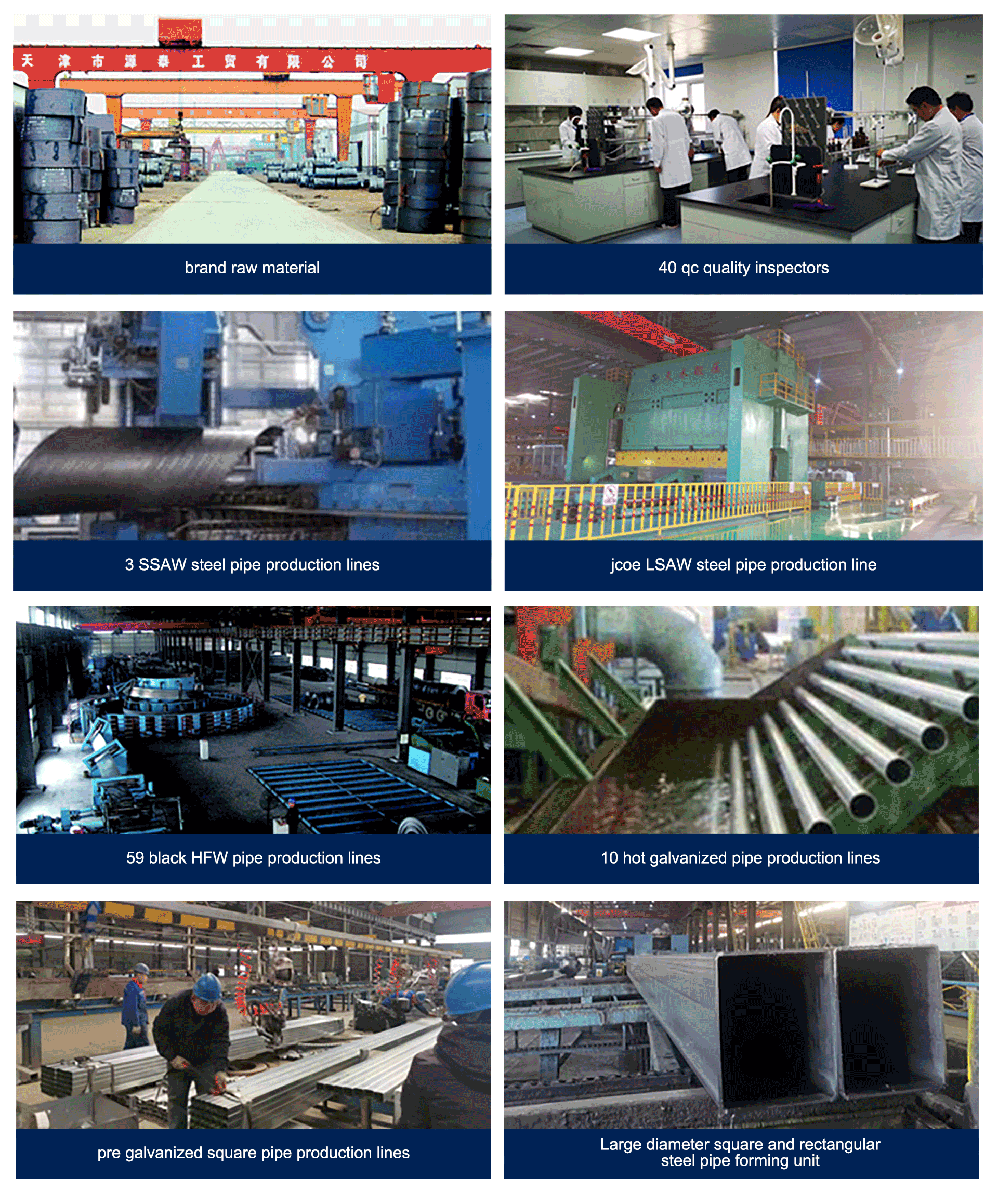

With an annual output of 10 million tons, Yuantai Derun is the largest manufacturer of ERW square pipes, rectangular pipes, hollow pipes, galvanized pipes, straight submerged arc welded steel pipes and spiral welded pipes in China. Annual sales reached 15 billion US dollars. Yuantai Derun has 59 black ERW pipe production lines, 10 galvanized pipe production lines and 3 spiral welded pipe production lines. Square pipe 10 * 10 * 0.5mm to 1000 * 1000 * 60MM, rectangular steel pipe 10 * 15 * 0.5mm to 800 * 1100 * 60MM, straight seam welded steel pipe φ 355.6-2000mm, spiral pipe Φ 219-2032mm, seamless pipe φ 21.3-820mm。 Yuantai Derun can produce square rectangular pipes conforming to ASTM A500, JIS g3466, en10219, din2240 and as1163. Yuantai Derun has the largest square tube inventory in China, which can meet the direct purchase needs of customers. Welcome to contact Yuantai Derun, e-mail: sales@ytdrgg.com , real-time connection factory inspection or factory visit!

Specification of square and rectangular hollow sections

| OD(MM) | THICKNESS(MM) | OD(MM) | THICKNESS(MM) | OD(MM) | THICKNESS(MM) | OD(MM) | THICKNESS(MM) |

| 20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

| 1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

| 1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

| 1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

| 1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

| 2.0 | 2.5-4.0 | 11.5-11.75 | |||||

| 20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | ||||

| 1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | |||

| 1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

| 1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

| 1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

| 2.2 | 2.20 | 13.5-13.75 | |||||

| 2.5-3.0 | 2.5-2.75 | 15.5-30 | |||||

| 20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | ||

| 1.4 | 5.5-6.3 | 4.5-4.75 | |||||

| 1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

| 2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

| 2.2 | 2.75 | 13.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | |||

| 3.25-4.0 | 5.5-6.3 | 4.5-4.75 | |||||

| 25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

| 1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

| 1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

| 1.8 | 3.0-3.75 | 12-13.75 | |||||

| 2.0 | 4.5-4.75 | 15.5-30 | |||||

| 2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | |||

| 2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

| 4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

| 5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

| 5.75-6.3 | 3.0-4.75 | 15.5-30 | |||||

| 40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 750*750 | ||

| 1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

| 2.2 | 2.75 | 15.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | |||

| 3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

| 4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

| 1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | ||||

| 1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | |||

| 1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

| 2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | ||||

| 3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | |||

| 4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

| 1.5 | 12.25 | 15.5-40 | |||||

| 1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 400*400 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | ||

| 1.8 | 4.5-6.3 | 9.5-9.75 | |||||

| 2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

| 2.2 | 9.5-9.75 | 12-13.75 | |||||

| 2.5-3.0 | 11.5-25 | 15.5-40 | |||||

| 3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1100*1100 | ||

| 4.25-4.75 | 3.5-3.75 | 11.5-11.75 | 20-60 | ||||

| 5.0-5.75 | 4.25-7.75 | 12-13.75 | |||||

| 7.5-8 | 9.5-25 | 15.5-40 |

01 DERECT DEAL

We have been specialized in

producing steel for many years

- 02 COMPLETE

- SPECIFICATIONS

OD:10*10-1000*1000MM 10*15-800*1100MM

Thickness:0.5-60mm

Length:1-24M

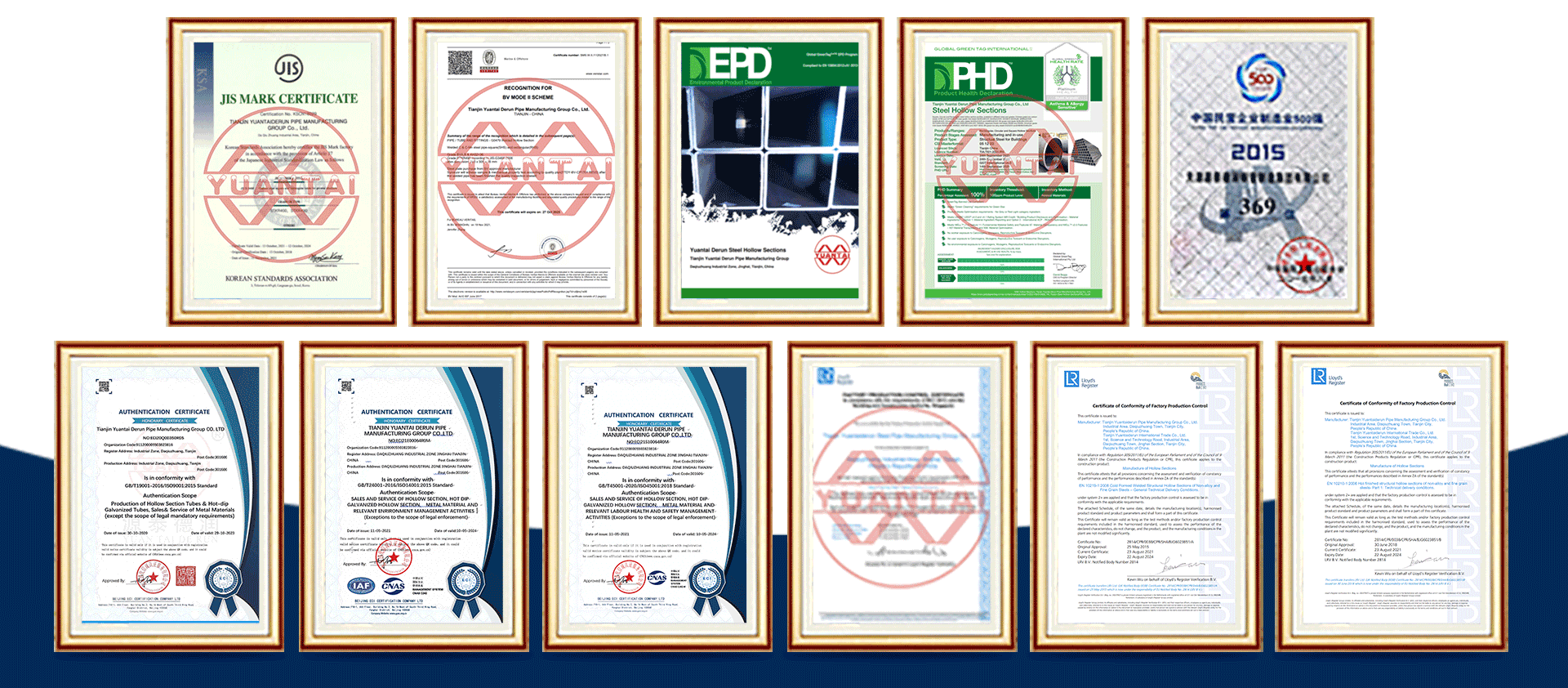

3 CERTIFICATION IS

COMPLETE

can produce steel pipe products of world

stardard,such as European standard,American standard,

Japanese standard,Astralian standard,natinal standard

and so on.

04 LARGE INVENTORY

Common specifications perennial inventory of

200000 tons

A: We are factory.

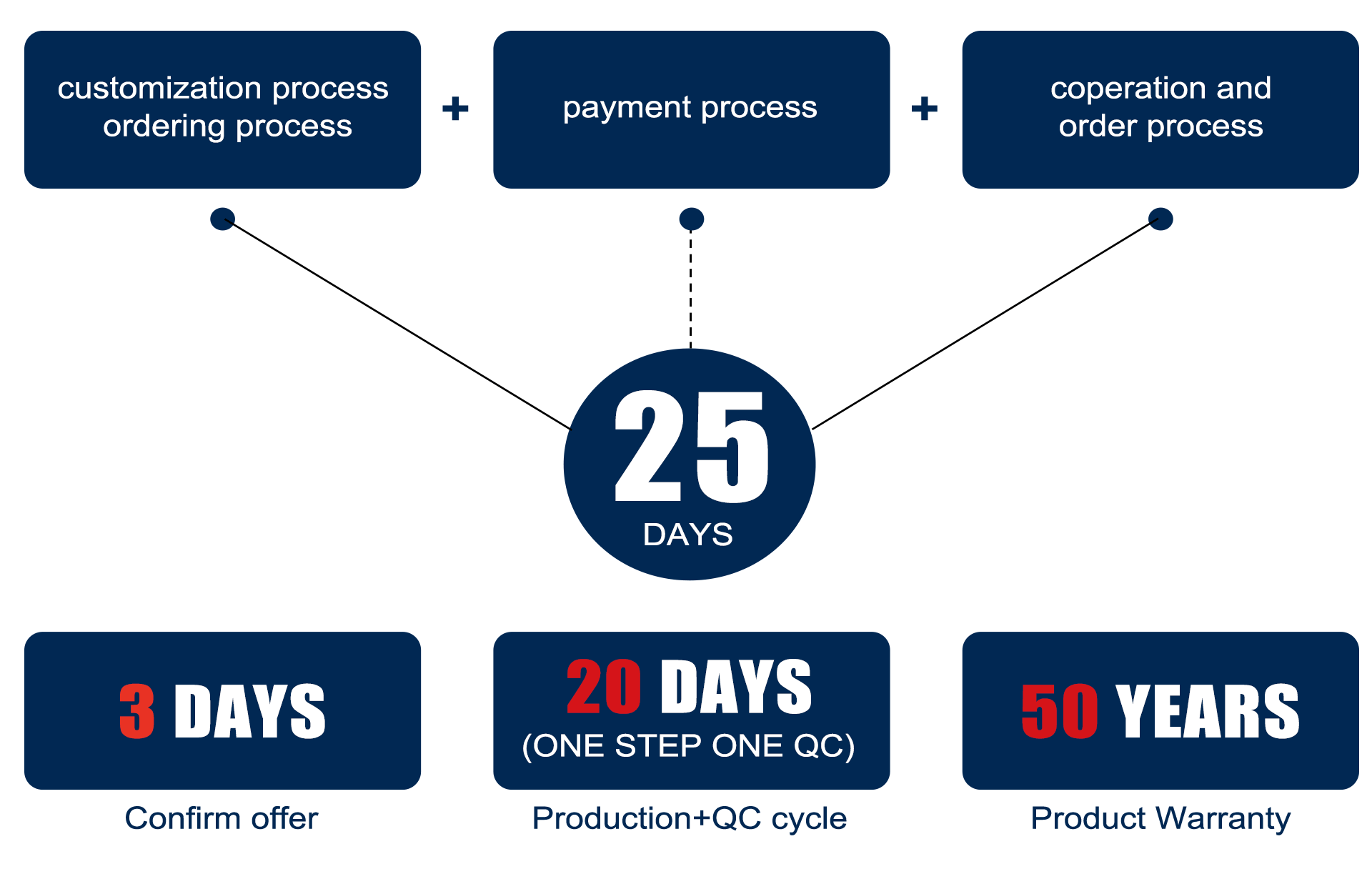

A: Generally it is 5-10 days if the goods are in stock. or it is 30 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge with the cost of freight paid by customer.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821