About product

We can ship the regular specifications to you with LCL service.

Anti-rusted oil painting,

varnish painting,

ral3000 painted,

galvanized,

3LPE, 3PP

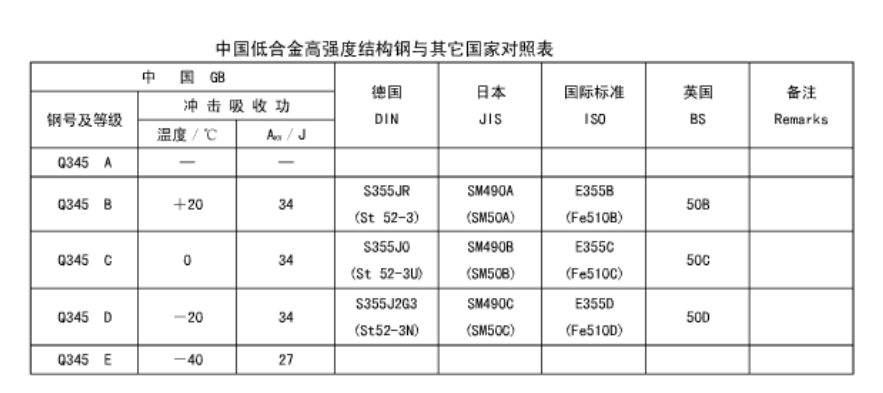

Q195 = S195 / A53 Grade A

Q235 = S235 / A53 Grade B / A500 Grade A / STK400 / SS400 / ST42.2

Q345 = S355JR / A500 Grade B Grade C

Q235 Al killed = EN39 S235GT

L245 = Api 5L / ASTM A106 Grade B

Black pipe is plain steel pipe without any protective coatings. Black pipe is used for a variety of applications around the home. It is very common to see black pipe used for your natural gas line and sprinkler system lines. Since black pipe has no protective coating, it may rust easily in wet or humid environments. To stop the pipe from rusting or corroding on the outside, you should provide a layer of protection on the outside of the pipe. The easiest method is painting it.

YES. We have strong cooperation with SINOSURE

RHS stands for Rectangular Hollow Section, that is rectangular steel pipe.

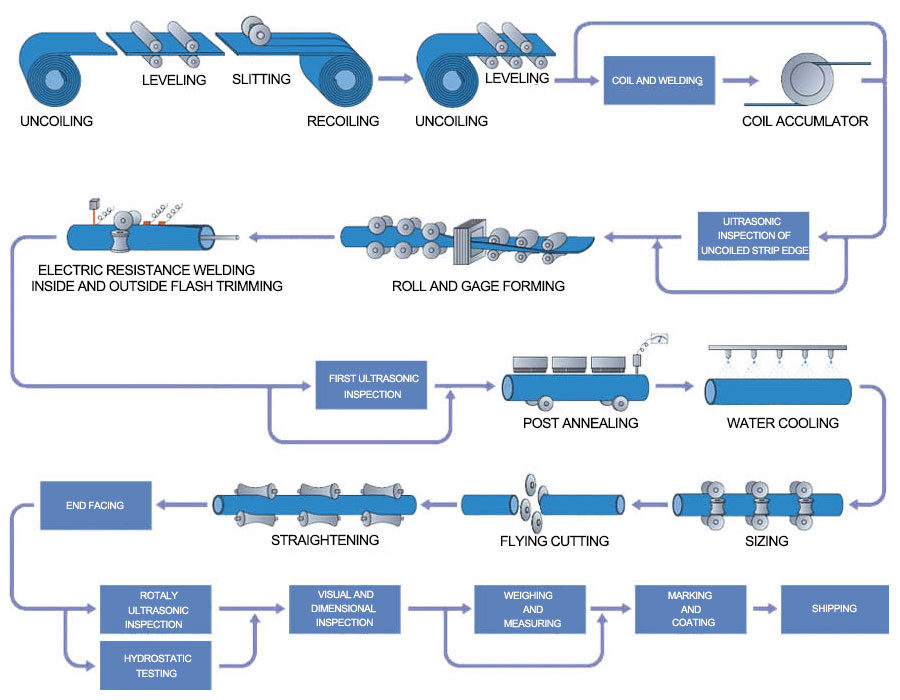

We also have square hollow section steel pipe, according to standard: ASTM A500 , EN10219 , JIS G3466 , GB/T6728 cold formed square and rectangular steel pipe.

ERW steel pipe, SSAW steel pipe, LSAW steel pipe, galvanized steel pipe, stainless steel pipe, casing and tubing pipe, elbow,reducer,tee,cap,coupling, flange,weldolet, Seamless steel pipe

TT, L/C(For big order,30-90 days can be acceptable).

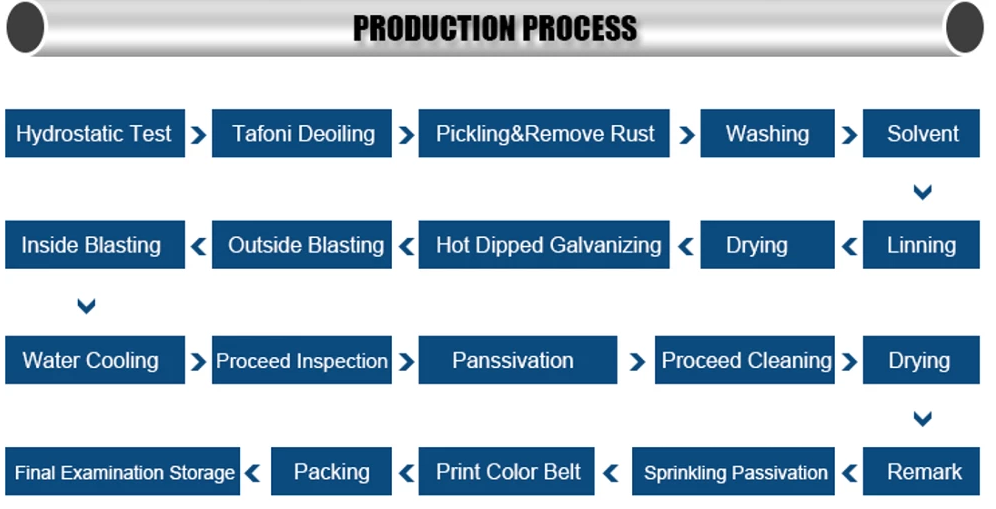

Galvanized steel pipes are divided into cold-dip galvanized steel pipes and hot-dip galvanized steel pipes. Galvanized pipes are usually used for water, gas, oil and other ordinary high-pressure fluid pipelines. They are also used in kerosene industry, especially oil field pipelines in offshore oil fields, coolers, coal steam exchange pipes and bridge pipe piles, mine support pipes, etc.

Galvanized steel pipes are divided into cold-dip galvanized steel pipes and hot-dip galvanized steel pipes. Galvanized pipes are usually used for water, gas, oil and other ordinary high-pressure fluid pipelines. They are also used in kerosene industry, especially oil field pipelines in offshore oil fields, coolers, coal steam exchange pipes and bridge pipe piles, mine support pipes, etc.

It is said that galvanized steel pipe is used for gas and heating. As a water pipe, a small amount of rust will be found after a few years. It not only pollutes sanitary ware, but also bacteria grow on the inner wall of the pipeline. Rust causes high metal content in the water body and endangers human health.

Hot dip galvanizing is to immerse the steel pipe in acid for washing, and prepare the aqueous solution with ammonium chloride aqueous solution or zinc chloride and zinc chloride, and pour it into the groove. Hot dip galvanized coating is uniform, with strong adhesion and long service life. The matrix of hot-dip galvanized steel pipe is a complex physical and molten electroplating solution, so the chemical reaction constitutes a compact layout and corrosion resistance. The alloy layer is fused with the pure zinc layer and the steel pipe base, so it has strong corrosion resistance.

Cold galvanized pipe is electro galvanized, and there is a great difference between corrosion resistance and hot-dip galvanized pipe. In order to ensure the quality, most formal galvanizing management manufacturers do not apply electro galvanizing (cold plating). Those informal small enterprises will use electro galvanizing because the price is relatively cheap. The galvanized layer of cold-dip galvanized steel pipe is a coating. The zinc layer is stacked independently with the steel pipe matrix. The zinc layer is thin, which is simply connected to the steel pipe and easy to fall off. Therefore, its corrosion resistance is poor. Therefore, for some directly buried pipelines, galvanized iron sheet steel pipes manufactured by regular manufacturers are still adopted.

How to remove rusty galvanized steel pipe?

First, apply the solvent to the outside of the steel to remove the organic matter. Rust can also be removed by pickling after brushing rust prevention, cleaning or iron, rust, welding slag, etc. Galvanizing is divided into thermoelectric coating and cold coating. Thermoelectric coating is not easy to rust and cold coating is easy to rust.

The current fire water supply pipe now basically uses galvanized pipe, and the outer layer of galvanized pipe is applied to a layer of paint. It can be seen that the fire pipe is actually galvanized. In steel structure, welding engineering has its participation. Therefore, the frequent use of galvanized steel pipe can prevent the occurrence of rust conditions for a long time.

1. OD 219mm and below In hexagonal seaworthy bundles packed by steel strips, With two nylon slings for each bundles

2. above OD 219mm in bulk or according to custom opinion

3. 25 tons/container and 5 tons/size for a trial order;

4. For 20" container the max length is 5.8m;

5. For 40" container the max length is 11.8m.

YES WE HAVE

YUANTAIDERUN Brand TOP 500 China

An iron-based mixture is considered to be an alloy steel when manganese is greater than 1.65%, silicon over 0.5%, copper above 0.6%, or other minimum quantities of alloying elements such as chromium, nickel, molybdenum, or tungsten are present. An enormous variety of distinct properties can be created for the steel by substituting these elements in the recipe.

A process for further refinement of stainless steel through reduction of carbon content

The amount of carbon in stainless steel must be lower than that in carbon steel or lower alloy steel (i.e., steel with alloying element content below 5%). While electric arc furnaces (EAF) are the conventional means of melting and refining stainless steel, AOD is an economical supplement, as operating time is shorter and temperatures are lower than in EAF steelmaking. In addition, using AOD for refining stainless steel increases the availability of the EAF for melting purposes.

Molten, unrefined steel is transferred from the EAF into a separate vessel. A mixture of argon and oxygen is blown from the bottom of the vessel through the melted steel. Cleaning agents are added to the vessel along with these gases to eliminate impurities, while the oxygen combines with carbon in the unrefined steel to reduce the carbon level. The presence of argon enhances the affinity of carbon for oxygen and thus facilitates the removal of carbon.

The corrosion of structural steel is an electrochemical process that requires the simultaneous presence of moisture and oxygen. In the absence of either, corrosion does not occur. Essentially, the iron in the steel is oxidised to produce rust, which occupies approximately 6 times the volume of the original material consumed in the process. The general corrosion process is illustrated here.As well as general corrosion, there are various types of localised corrosion that can also occur; bimetallic corrosion, pitting corrosion and crevice corrosion. However, these tend not to be significant for structural steelwork.The rate at which the corrosion process progresses depends on a number of factors relating to the ‘micro-climate’ immediately surrounding the structure, principally the time of wetness and the atmospheric pollution level. Because of variations in atmospheric environments, corrosion rate data cannot be generalised. However, environments can be broadly classified, and corresponding measured steel corrosion rates provide a useful indication of likely corrosion rates. More information can be found in BS EN ISO 12944-2 and BS EN ISO 9223

Painted SHS (square hollow sections) and RHS (rectangular hollow sections) are high-strength cold-formed hollow steel sections that are primer painted for protection during storage and handling.

Image result for Hot dip galvanized square steel pipe

In long-term, continuous exposure, the recommended maximum temperature for hot-dip galvanized steel is 200 °C (392 °F), according to the American Galvanizers Association. The use of galvanized steel at temperatures above this will result in peeling of the zinc at the inter metallic layer.

It means square hollow section which is abbreviated as SHS

It means circular hollow section, which is abbreviated as SHS.

About delivery

Generally it is 3-5 days if goods are in stock. or around 25 days if the goods are not in stock and it is according to order requirement.

To South Africa: 45 days

To Middle East: 30 days

To South America: 60 days

To North America: 30 days

To Russia: 7 days

To Europe: 45 days

To South Korea: 5 days

To Japan: 5 days

To Vietnam: 15 days

To Thailand: 15 days

To India: 30 days

To Indonesia: 15 days

To Singapore: 10 days

About service

YUANTAIDERUN GOOD QUALITY GOOD PRICE GOOD SERVCE.

We have a professional laboratory,

And professional testing personnel.

Quality/Quantity Claims: The Buyer is entitled to make both quality and quantity claim in writing against the Seller within 90 days after arrival at the port of destination.

EN210 EN219 BC1 API UL ISO FPC CE EPD PHD JIS3466 GB

A: 1.We keep good quality and competitive price to ensure our customers' benefit.

2.We respect every customer as our friend and we sincerrly do business and make friends with them, no matter where they come from.

Yes,you can get available samples in our stock.Free for real samples,but customers need to pay the freight cost.

The possibilities for using steel in buildings and infrastructure are limitless. The most common applications are listed below.For buildingsStructural sections: these provide a strong, stiff frame for the building and make up 25% of the steel use in buildings.Reinforcing bars: these add tensile strength and stiffness to concrete and make up 44% of steel use in buildings. Steel is used because it binds well to concrete, has a similar thermal expansion coefficient and is strong and relatively cost-effective. Reinforced concrete is also used to provide deep foundations and basements and is currently the world’s primary building material.Sheet products: 31% is in sheet products such as roofing, purlins, internal walls, ceilings, cladding, and insulating panels for exterior walls.Non-structural steel: steel is also found in many non-structural applications in buildings, such as heating and cooling equipment and interior ducting.Internal fixtures and fittings such as rails, shelving and stairs are also made of steel. For infrastructureTransport networks: steel is required for bridges, tunnels, rail track and in constructing buildings such as fueling stations, train stations, ports and airports. About 60% of steel use in this application is as rebar and the rest is sections, plates and rail track.Utilities (fuel, water, power): over 50% of the steel used for this application is in underground pipelines to distribute water to and from housing, and to distribute gas. The rest is mainly rebar for power stations and pumping houses.