Neffens de American Petroleum Institute Standard API SPEC 5CT1988 1e edysje kin de stielkwaliteit fan API 5CT oaljemantelpiip wurde ferdield yn tsien soarten, ynklusyf H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 en Q-125. Wy leverje de mantelpiip en API 5CT K55 Mantelbuizen mei tried en koppeling, of wy biede ús produkt oan neffens de folgjende foarmen as opsje.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

API 5CT K55 Casing Tubing Spesifikaasjes

| API 5CT K55 CASING TUBING SPESIFIKAASJES | ||

| Beskikbere maten | 2 3/8″, 2 7/8″ en 3 ½” bûtenste diameter | |

| Sifers | J55, J55-FBNAU, N80, L80, P110 | |

| Slangen | 1 1/4 “ – 2 1/16” Nominaal. | |

| Normen | API SPEC 5CT | |

| Model yn gewoan gebrûk | 2-3/8″, 2-7/8″, 3-1/2″, 4″, 4-1/2″ | |

| Lingteberik | R1 (6,10-7,32 m), R2 (8,53-9,75 m), R3 (11,58-12,8 m) | |

| Stielkwaliteit (omhulselkwaliteiten, buizenkwaliteiten) | J55, K55, N80-1, N80-Q, L80, P110 | |

| Type skroefdraad | Net-oerstjoere skroefdraad ein (NUE), Eksterne oerstjoere skroefdraad ein (EUE) | |

| Spesjaliteiten |

| |

| Einôfwerking | Eksterne Upset Ends (EUE), Flush Joint, PH6 (en lykweardige ferbiningen), Yntegraal Joint (IJ) | |

API 5CT K55 Trek- en hurdheidseasken foar behuizingsbuizen

| Groep | Klasse | Type | Totale ferlinging ûnder lading % | Opbringststerkte MPa | Treksterkte min. MPa | Maksimum hurdens. | Spesifisearre muorredikte mm | Tastiene hurdheidsfariaasje b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | maks. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 oant 19.04 19.05 oant 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 oant 19.04 19.05 oant 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12,70 12,71 oan 19,04 19,05 oan 25,39. ≥ 25,40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 oant 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aYn gefal fan skeel sil laboratoarium Rockwell C-hurdenstest brûkt wurde as skiedsrjochtermetoade. bDer binne gjin hurdheidsgrinzen oantsjutte, mar de maksimale fariaasje is beheind neffens 7.8 en 7.9 fan API Spec. 5CT. | ||||||||||

K55 Behuizingsbuizen Ofmjittings

| Piipbehuizingsgrutte, oaljefjildbehuizingsgrutte en behuizingsdriftgrutte | |

|---|---|

| Bûtenste diameter (maten fan 'e omhulselpiip) | 4 1/2″-20″, (114.3-508mm) |

| Standert behuizingsgrutte | 4 1/2″-20″, (114.3-508mm) |

| Triedtype | Steunbeugel triedbehuizing, lange rûne triedbehuizing, koarte rûne triedbehuizing |

| Funksje | It kin de buis beskermje. |

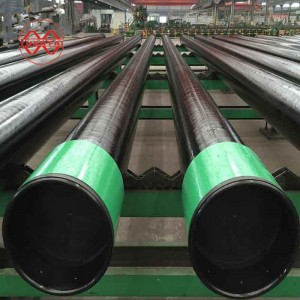

Oaljebuis foar petroleum- en ierdgasyndustry

| Namme fan pipen | Spesifikaasje | Stielgraad | Standert | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Petroleum Casing Pipe | 127-508 | 5.21-16.66 | 6-12 | J55M55.K55. L80. N80P110. | API Spesifikaasje 5CT (8) |

| Petroleumbuizen | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spesifikaasje 5CT (8) |

| Koppeling | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spesifikaasje 5CT (8) |

API 5CT K55 Behuizingsbuizen Eigenskippen

- API 5CT K55 Casing Tubing wurdt oanbean mei in frije lingteberik fan 8m oant 13m op basis fan 'e SY/T6194-96-norm. It is lykwols ek beskikber mei in lingte fan net minder as 6m en de kwantiteit dêrfan moat net mear as 20% wêze.

- Deformaasjes dy't hjirboppe neamd binne, meie net ferskine op it bûtenste oerflak fan 'e API 5CT K55 Casing Tubing-koppeling.

- Elke deformaasje lykas hierline, skieding, kreuk, barst of skurf is net akseptabel op sawol de binnen- as de bûtenste oerflakken fan it produkt. Al dizze defekten moatte folslein fuorthelle wurde en de fuorthelle djipte mei net mear as 12,5% fan 'e nominale wanddikte wêze.

- It oerflak fan 'e tried fan' e koppeling en API 5CT K55 Casing Tubing moat glêd wêze sûnder bramen, skuorren of oare defekten dy't in negative ynfloed kinne hawwe op 'e sterkte en nauwe ferbining.

It is wichtich foar oalje- en gasoperators om har produksjeputomhulsels te beskermjen tsjin korrosje mei kathodyske beskerming en API 5CT OilField Tubing tsjinnet benammen foar it oerdragen fan oalje en gassen.

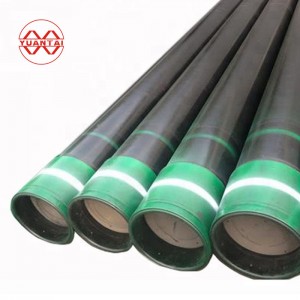

API 5CT Grade K55 Casing Tubing Steel Kleurkoade

| Namme | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Behuizing | in helder griene bân | twa helder griene bannen | in helder reade bân | in helder reade bân + in griene bân | in reade bân + in brune bân | in helder wite bân |

| Koppeling | hiele griene koppeling + in wite bân | hiele griene koppeling | hiele reade koppeling | hiele reade koppeling + in griene bân | hiele reade koppeling + in brune bân | hiele wite koppeling |

ISO/API-behuizing/API 5CT K55-behuizingsbuizenspesifikaasjes

| Koade | Bûtenste Dia | Nominaal gewicht (mei tried en koppeling) b,c | Muurdikte | Einferwurkingstype | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Pûn/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Omhulsel piip Codea | API 5CT Omhulsel piip Bûtenste diameter | API 5CT Casing piip Nominaal gewicht (mei tried en koppeling) b,c | API 5CT Omhulsel piip Wanddikte | API 5CT Casing piip Einferwurkingstype | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Pûn/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32,75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Koarte rûne tried, L-Lange rûne tried, B-Steuntried | ||||||||||||

| a. Koade wurdt brûkt foar bestelreferinsje. | ||||||||||||

| b. It nominale gewicht fan 'e skroefdraad- en keppele behuizing (kolom 2) wurdt allinich ter referinsje werjûn. | ||||||||||||

| c. Martensitysk chromiumstiel (L80 9Cr en 13Cr) ferskilt fan koalstofstiel yn tichtheid. It werjûne gewicht fan martensitysk chromiumstiel is gjin krekte wearde. De massa-korreksjefaktor 0.989 kin brûkt wurde. | ||||||||||||

| d. De behuizing fan stiel fan C90, T95 en Q125 moat levere wurde neffens de spesifikaasje, it gewicht en de wanddikte dy't neamd binne yn 'e boppesteande tabel of bestelling. | ||||||||||||

API 5CT K55 Gemyske Gearstalling

| Groep | Klasse | Type | C | Mn | Mo | Cr | Ni maks. | Cu maks. | P maks. | S maks. | Si maks. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | maks. | min. | maks. | min. | maks. | min. | maks. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0,45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 in | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0,25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0,25 dagen | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a It koalstofgehalte foar L80 kin ferhege wurde oant maksimaal 0,50% as it produkt oalje-blust wurdt. b It molybdeengehalte foar Grade C90 Type 1 hat gjin minimale tolerânsje as de wanddikte minder is as 17,78 mm. c It koalstofgehalte foar R95 kin ferhege wurde oant maksimaal 0,55% as it produkt oaljeblêst wurdt. d It molybdeengehalte foar T95 Type 1 kin fermindere wurde nei minimaal 0,15% as de wanddikte minder is as 17,78 mm. e Foar EW Grade P110 moat it fosforgehalte maksimaal 0,020% wêze en it swevelgehalte maksimaal 0,010%. NL = gjin limyt. De werjûne eleminten moatte rapportearre wurde yn produktanalyse. | |||||||||||||||

API 5CT k55 Gr. Mechanyske eigenskippen

| API 5CT Casing Standert | Type | API 5CT Treksterkte fan 'e behuizing MPa | API 5CT Casing Opbringststerkte MPa | API 5CT Behuizinghurdens Maks. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | —- |

| K55 | ≥517 | ≥655 | — | |

| N80 | ≥689 | 552 ~ 758 | — | |

| L80 (13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | —- |

Mei in jierlikse produksje fan 5 miljoen ton is Yuantai Derun de grutste fabrikant fan ERW fjouwerkante piip, rjochthoekige piip, holle piip, galvanisearre piip en spiraallaske piip yn Sina. De jierlikse ferkeap berikte $15 miljard. Yuantai Derun hat 59 produksjelinen foar swarte ERW-pipen, 10 produksjelinen foar galvanisearre piip en 3 produksjelinen foar spiraallaske piip. Fjouwerkante piip 20 * 20 * 1 mm oant 500 * 500 * 40 mm, rjochthoekige stielen piip 20 * 30 * 1,2 mm oant 400 * 600 * 40 mm, spiraalpiip Ø 219-1420 mm kinne makke wurde fan stielkwaliteiten fan Q (s) 195 oant Q (s) 345B / gr.a-gr.d. Yuantai Derun kin fjouwerkante rjochthoekige buizen produsearje neffens ASTM A500, JIS g3466, en10219, din2240 en as1163. Yuantai Derun hat de grutste ynventaris fan fjouwerkante rjochthoekige buizen yn Sina, dy't kin foldwaan oan 'e direkte oankeapfraach fan klanten.

Wolkom elkenien om kontakt op te nimmen mei Yuantai Derun, e-post:sales@ytdrgg.com, en ynspeksje fan ferbining yn echte tiid oan in fabryk of in besite oan de fabryk!

| Produkt | Api 5L X42/X52/X60/X70 |

| Standert | Api 5L |

| Klasse | X42, X52, X60, X65, X70 |

| Technyk | Kâld rôle |

| bûtendiameter mm | 21,3 mm 2032 mm |

| Gewicht mm | 0.5mm-60mm |

| Lingte | 5.8m/6m/11.8m/12m of as nedich |

| Oerflak | Swart skilderjen/galvanisearre/lak/3LPE-coating/bleat |

| Plak fan oarsprong | Sina (fêstelân) |

| Oanfraach | 1.Flüssige piip |

| 2. Oaljepipe | |

| 3. Gaslieding | |

| 4. Boilerbuizen | |

| 5.Struktuerpiip | |

| 6. Dongstofbuis ensfh. | |

| Ynpakken | Piip ûnder 8 inch sil yn bondel wêze. Boppe sil bulk wêze. |

| Hannelsbetingsten | FOB, CFR, CIF, CIP ensfh. |

| Betellingstermyn | 1.30% TT foarútbetelling en it saldo betelle nei ynspeksje |

| 2.LC op sicht | |

| Levertiid | 7-30 wurkdagen nei ûntfangst fan foarôfbetelling of LC |

FABRIK ARBEIDERS SHOW

Froulju binne net minderweardich oan manlju.

Konsekwinte oanhâldendheid hat in inkele kampioen fan in kategory berikt

Tiid kin alles feroarje, mar tiid feroaret miskien net alles, bygelyks it earste hert

Yuantai-minsken dy't fjochtsje yn ferskate posten

FABRYK WORKSHOP SHOW

PRESINTAASJE FAN IT KLANTTEAM

LEVERING EN LOGISTYK

It bedriuw hechtet grutte wearde oan 'e kwaliteit fan produkten, ynvestearret swier yn 'e ynfiering fan avansearre apparatuer en professionals, en docht alles om te foldwaan oan 'e behoeften fan klanten yn binnen- en bûtenlân.

De ynhâld kin rûchwei wurde ferdield yn: gemyske gearstalling, reksterkte, treksterkte, ynfloedeigenskip, ensfh.

Tagelyk kin it bedriuw ek online foutdeteksje en gloeien en oare waarmtebehannelingsprosessen útfiere neffens de behoeften fan 'e klant.

https://www.ytdrintl.com/

E-post:sales@ytdrgg.com

Tianjin YuantaiDerun stielen buizenproduksjegroep Co., Ltd.is in stielen piipfabryk sertifisearre trochEN/ASTM/ JISspesjalisearre yn 'e produksje en eksport fan alle soarten fjouwerkante rjochthoekige piip, galvanisearre piip, ERW-laske piip, spiraalpiip, ûnderdompele bôge-laske piip, rjochte naadpiip, naadleaze piip, kleurcoated stielen coil, galvanisearre stielen coil en oare stielprodukten. Mei handich ferfier is it 190 kilometer fuort fan Beijing Capital International Airport en 80 kilometer fuort fan Tianjin Xingang.

WhatsApp: +8613682051821