Manufacturing process of galvanized coil

Ore-----> iron-----> steel-----> slab continuous casting -----> hotrolling -----> pickling-----> cold rolling -----> galvanized

Welcome everyone to cantact Yuantai Derun,E-mail:sales@ytdrgg.com, and Real time connection inspection plant or factory visit!

FAQ

1.How long is the service life of galvanized coil?

The service life of hot galvanizing is generally not less than 10 years.

2. What is the main purpose of hot dip galvanized sheet?

Answer: hot dip galvanized sheet is mainly used in construction, home appliances, automobile, machinery, electronics, light industry and other industries

3. What are the two types of hot dip galvanizing according to the different annealing methods?

Answer: it can be divided into two types: in-line annealing and out of line annealing, which are also called shielding gas method and flux method.

4. What are the common steel types of hot-dip galvanized sheet?

Answer: product categories: general commodity coil (CQ), structural galvanized sheet (HSLA), deep drawing hot galvanized sheet (DDQ), bake hardening hot galvanized sheet (BH), dual phase steel (DP), TRIP steel (phase transformation induced plastic steel), etc.

5. What are the forms of galvanizing annealing furnace?

Answer: there are three kinds of vertical annealing furnace, horizontal annealing furnace and vertical and horizontal annealing furnace.

6. How many cooling methods are there for the cooling tower?

Answer: there are two types: air cooling and water cooling.

7. What are the main defects of hot dip galvanizing?

Answer: it mainly includes: falling off, scratch, passivation spot, zinc particle, thick edge, air knife scratch, air knife scratch, exposed steel, inclusion, mechanical damage, poor performance of steel base, wavy edge, scoop bend, size mismatch, embossing, zinc layer thickness mismatch, roller printing, etc.

8. What are the main reasons for zinc layer falling off?

Answer: the main reasons for the zinc layer falling off are: surface oxidation, silicon compounds, too dirty cold-rolled emulsion, too high oxidation atmosphere and protective gas dew point in the NOF section, unreasonable air-fuel ratio, low hydrogen flow, oxygen infiltration in the furnace, low temperature of strip steel entering the boiler, low furnace pressure in the RWP section and air suction at the furnace door, low furnace temperature in the NOF section, insufficient oil evaporation, low aluminum content in the zinc pot, too fast unit speed, insufficient reduction The residence time in the molten zinc is too short and the coating is too thick.

9. What are the causes of white rust and black spots?

Answer: black spots are formed by further oxidation of white rust. The main causes of white rust are:

Poor passivation, insufficient or uneven passivation film thickness; The surface is not coated with oil or the water remains on the surface of the strip steel; There is moisture on the surface of strip steel during coiling; Passivation is not completely dried; Damp or rain during transportation or storage; The storage time of finished products is too long; The galvanized sheet is in contact with other corrosive media such as acid and alkali or stored together.

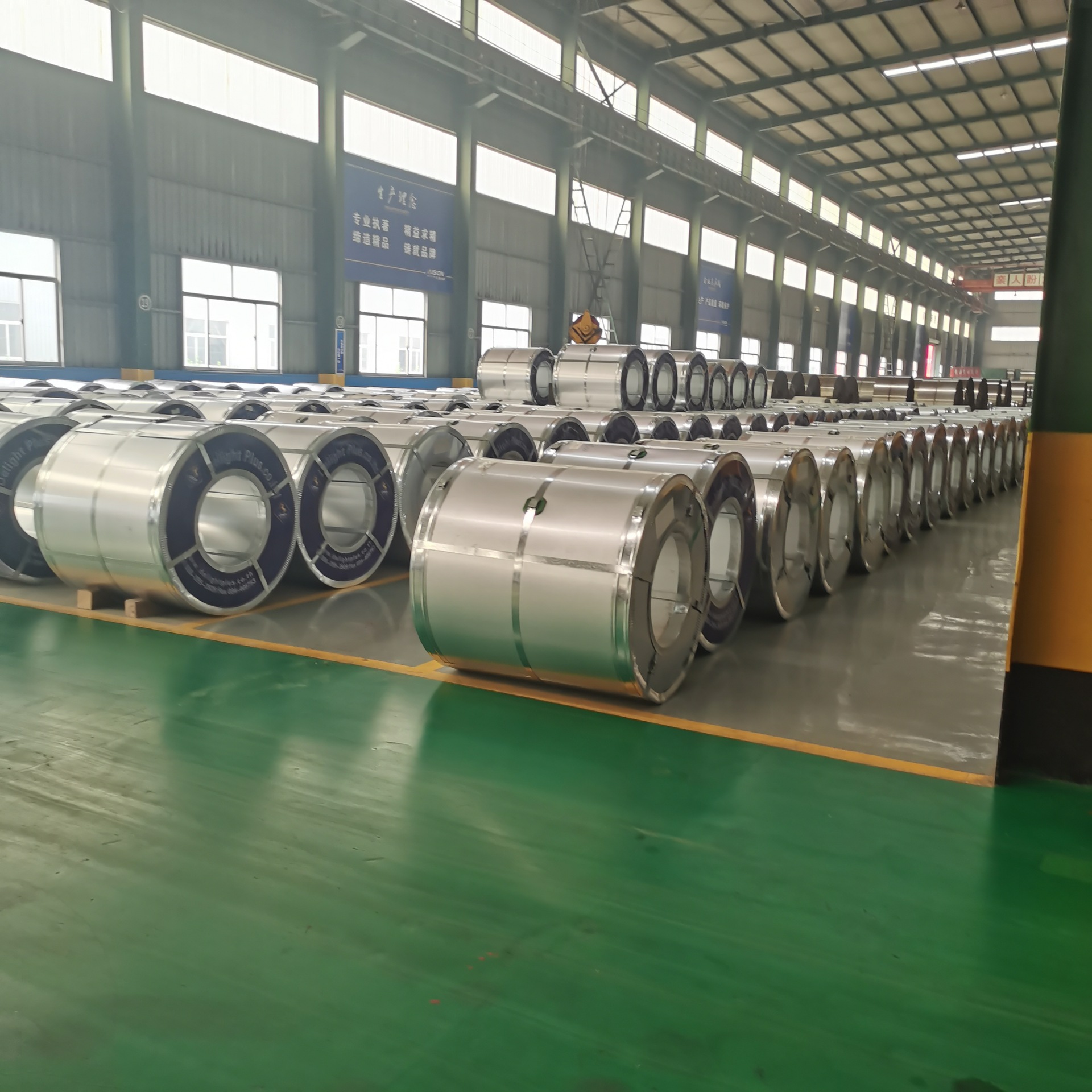

Packaging and logistics

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

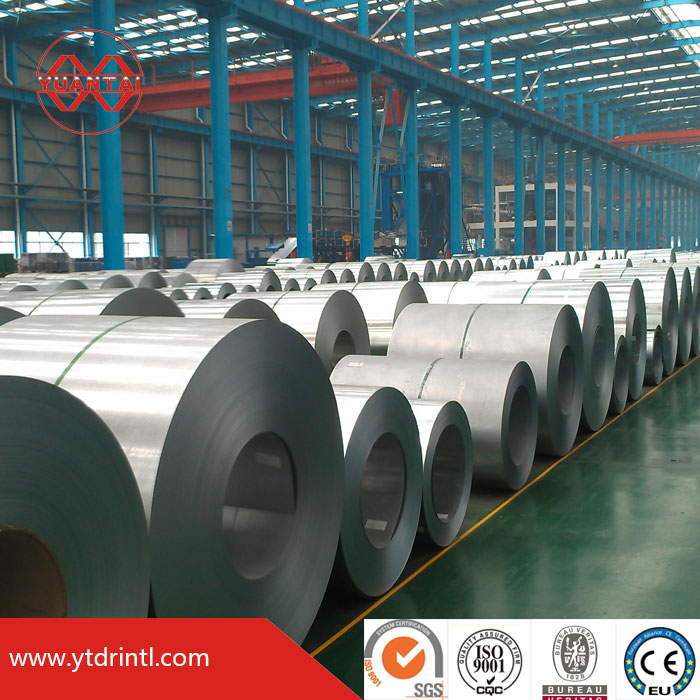

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821