A rèir Inbhe Institiùd Peatrail Ameireagaidh API SPEC 5CT1988 1d deasachadh, faodar ìre stàilinn pìob còmhdach ola API 5CT a roinn ann an deich seòrsaichean, nam measg H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 agus Q-125. Bidh sinn a’ toirt seachad a’ phìob còmhdach & Tiùban Còmhdach API 5CT K55 còmhla ri snàthainn agus ceangal, no bidh sinn a’ tabhann ar bathar a rèir nan cruthan a leanas airson roghainn.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Sònrachaidhean Tiùbaidh Casaidh API 5CT K55

| SÒNRAICHEAN TIÙBAN CÀIS API 5CT K55 | ||

| OD | 10.3mm-2032mm | |

| Inbhean | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Raon Fad | 3-12M no a rèir riatanas an neach-dèiligidh | |

| Gràd Stàilinn (Gràdan Còmhdach, Gràdan Tiùban) | Ìre A, Ìre B, Ìre C, X42, X52, X60, X65, X70 | |

| Seòrsa Snàthainn Sgriubha | Ceann snàthaichte neo-thruaillidh (NUE), ceann snàthaichte taobh a-muigh troimh-chèile (EUE) | |

| Speisealachdan |

| |

| Crìochnachadh Deireannach | Ceannan Taobh a-muigh air an cur tro chèile (EUE), Co-bhonn Sruthach, PH6 (agus ceanglaichean co-ionann), Co-bhonn Amalaichte (IJ) | |

Riatanas teannachaidh is cruas tiùban còmhdach API 5CT K55

| Buidheann | Ìre | Seòrsa | Leudachadh iomlan fo luchd % | Neart toraidh MPa | Neart teannachaidh MPa as ìsle | Cruas as àirde. | Tiughas balla sònraichte mm | Atharrachadh cruas ceadaichte b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| mion. | as àirde. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 gu 19.04 19.05 gu 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 gu 19.04 19.05 gu 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 gu 19.04 19.05 gu 25.39 . ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 gu 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aMa tha connspaid ann, thèid deuchainn cruas Rockwell C obair-lann a chleachdadh mar dhòigh-rèiteachaidh. bChan eil crìochan cruas air an sònrachadh, ach tha an atharrachadh as motha air a chuingealachadh a rèir 7.8 agus 7.9 de Shònrachadh API 5CT. | ||||||||||

Meudan Tiùban Còmhdach K55

| Meudan Còmhdach Phìoban, Meudan Còmhdach Achaidh Ola & Meudan Drift Còmhdach | |

|---|---|

| Trast-thomhas a-muigh (Meudan Pìoba Casaidh) | 4 1/2"-20", (114.3-508mm) |

| Meudan Còmhdach Coitcheann | 4 1/2"-20", (114.3-508mm) |

| Seòrsa Snàthainn | Còmhdach snàthainn taice, còmhdach snàthainn cruinn fada, còmhdach snàthainn cruinn goirid |

| Gnìomh | Faodaidh e pìob a dhìon. |

Tiùb Ola airson Gnìomhachasan Peatrail is Gas Nàdarra

| Ainm nam Pìoban | Sònrachadh | Ìre stàilinn | Coitcheann | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Pìob Casaidh Peatrail | 127-508 | 5.21-16.66 | 6-12 | J55M55.K55. L80. N80P110. | Sònrachadh API 5CT (8) |

| Tiùban Peatrail | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | Sònrachadh API 5CT (8) |

| Ceangal | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Sònrachadh API 5CT (8) |

Feartan Tiùbaidh Casaidh API 5CT K55

- Tha Tiùban Còmhdach API 5CT K55 air an tabhann le raon faid shaor bho 8m gu 13m stèidhichte air norm SY/T6194-96. Ach, tha e ri fhaighinn cuideachd co-dhiù 6m de dh'fhaid agus cha bu chòir a mheud a bhith nas motha na 20%.

- Chan eil cead aig deformachaidhean a chaidh ainmeachadh gu h-àrd nochdadh air uachdar a-muigh ceangal tiùban còmhdach API 5CT K55.

- Chan eil deformachadh sam bith leithid loidhne fuilt, dealachadh, lùbadh, sgàineadh no sgreab ceadaichte air uachdar a-staigh agus a-muigh an toraidh. Bu chòir na h-uireasbhaidhean seo uile a thoirt air falbh gu tur agus chan fhaod an doimhneachd a chaidh a thoirt air falbh a bhith nas àirde na 12.5% de thiughas balla ainmichte.

- Bu chòir uachdar snàthainn a’ cheangail agus tiùban còmhdach API 5CT K55 a bhith rèidh gun burr, reubadh no uireasbhaidhean eile a dh’ fhaodadh droch bhuaidh a thoirt air neart agus ceangal dlùth.

Tha e cudromach do luchd-obrachaidh ola is gas na còmhdachaidhean tobair cinneasachaidh aca a dhìon bho chreimeadh le dìon cathodic & tha Tiùban Achaidh-Ola API 5CT sa mhòr-chuid a’ frithealadh airson ola is gasaichean a ghluasad.

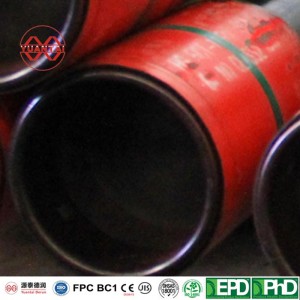

Còd dath stàilinn tiùbaidh còmhdach API 5CT Ìre K55

| Ainm | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Còmhdach | còmhlan uaine soilleir | dà chòmhlan uaine soilleir | còmhlan dearg soilleir | còmhlan dearg soilleir + còmhlan uaine | còmhlan dearg + còmhlan donn | còmhlan geal soilleir |

| Ceangal | ceangal uaine gu lèir + còmhlan geal | ceangal uaine gu lèir | ceangal dearg gu lèir | ceangal dearg gu lèir + còmhlan uaine | ceangal dearg gu lèir + còmhlan donn | ceangal geal gu lèir |

Sònrachaidhean tiùban còmhdach ISO/API/API 5CT K55

| Còda | Dia a-muigh | Cuideam ainmichte (le snàthainn agus ceangal) b,c | Tiughas Balla | Seòrsa giollachd crìochnachaidh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | lb/tr | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Pìob Casaidh API 5CT Codea | Trast-thomhas a-muigh pìob casaidh API 5CT | Cuideam ainmichte pìob casaidh API 5CT (le snàthainn agus ceangal) b,c | Tiughas balla pìoba casaidh API 5CT | Pìob casaidh API 5CT Seòrsa giollachd deiridh | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | lb/tr | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Snàthainn chruinn ghoirid, L-Snàthainn chruinn fhada, B-Snàthainn taice | ||||||||||||

| a. Tha còd air a chleachdadh airson fiosrachadh òrdachaidh. | ||||||||||||

| b. Chan eil cuideam ainmichte a’ chèidse snàthaichte is ceangailte (colbh 2) air a shealltainn ach airson fiosrachaidh. | ||||||||||||

| c. Tha stàilinn cròmium martensitic (L80 9Cr agus 13Cr) eadar-dhealaichte bho stàilinn charboin ann an dùmhlachd. Chan e luach mionaideach a th’ ann an cuideam stàilinn cròmium martensitic a tha air a shealltainn. Faodar am factar ceartachaidh mais 0.989 a chleachdadh. | ||||||||||||

| d. Bu chòir còmhdach ìre stàilinn C90, T95 agus Q125 a thoirt seachad a rèir an t-sònrachaidh, cuideam agus tighead balla a tha air an liostadh sa chlàr no san òrdugh gu h-àrd. | ||||||||||||

Co-dhèanamh Ceimigeach API 5CT K55

| Buidheann | Ìre | Seòrsa | C | Mn | Mo | Cr | Chan eil e cho mòr. | Cu as àirde. | P as àirde. | S as àirde. | Si as àirde. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mion. | as àirde | mion. | as àirde | mion. | as àirde | mion. | as àirde | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 latha | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| Faodar susbaint gualain L80 a mheudachadh suas ri 0.50% aig a’ char as àirde ma thèid an toradh a mhùchadh le ola. Chan eil fulangas as ìsle aig susbaint molybdenum airson Gràd C90 Seòrsa 1 ma tha tiughas a’ bhalla nas lugha na 17.78 mm. Faodar susbaint gualain R95 a mheudachadh suas ri 0.55% aig a’ char as àirde ma thèid an toradh a mhùchadh le ola. Faodar susbaint molybdenum airson T95 Seòrsa 1 a lùghdachadh gu 0.15% aig a’ char as lugha ma tha tiughas a’ bhalla nas lugha na 17.78 mm. Airson EW Ìre P110, bidh an susbaint fosfair aig a’ char as àirde 0.020% agus an susbaint sulfair aig a’ char as àirde 0.010%. NL = gun chrìoch. Feumar na h-eileamaidean a chithear aithris ann an mion-sgrùdadh toraidh. | |||||||||||||||

Feartan Meacanaigeach API 5CT k55 Gr.

| Inbhe Còmhdach API 5CT | Seòrsa | Neart Tensile Casing API 5CT MPa | Neart Toraidh Casaidh API 5CT MPa | Cruas Còmhdach API 5CT Uasmhéid. |

|---|---|---|---|---|

| Sònrachadh API 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Tha a’ chompanaidh a’ cur cudrom mòr air càileachd thoraidhean, a’ tasgadh gu mòr ann an toirt a-steach uidheamachd agus proifeiseantaich adhartach, agus a’ dèanamh a h-uile rud a dh’ fheumas iad gus coinneachadh ri feumalachdan luchd-ceannach aig an taigh agus thall thairis.

Faodar an susbaint a roinn gu garbh ann an: co-dhèanamh ceimigeach, neart toraidh, neart tensile, feartan buaidh, msaa.

Aig an aon àm, faodaidh a’ chompanaidh lorg lochtan air-loidhne agus annealing agus pròiseasan làimhseachaidh teas eile a dhèanamh a rèir feumalachdan luchd-ceannach.

https://www.ytdrintl.com/

Post-d:sales@ytdrgg.com

Buidheann Saothrachaidh Tiùban Stàilinn Tianjin YuantaiDerun Co., Ltd.a bheil factaraidh phìoban stàilinn barrantaichte leEN/ASTM/ JISa’ speisealachadh ann an cinneasachadh agus às-mhalairt a h-uile seòrsa pìob ceart-cheàrnach ceàrnagach, pìob ghalbhanaichte, pìob tàthaichte ERW, pìob shnìomhanach, pìob tàthaichte bogha fon uisge, pìob seam dìreach, pìob gun fhàinne, coil stàilinn còmhdaichte le dath, coil stàilinn ghalbhanaichte agus toraidhean stàilinn eile. Le còmhdhail goireasach, tha e 190 cilemeatair air falbh bho Phort-adhair Eadar-nàiseanta Prìomh-bhaile Beijing agus 80 cilemeatair air falbh bho Tianjin Xingang.

Whatsapp: +8613682051821