YuantaiDerunsquare rectangular tube yana da fiye da 63 hažžožin, wanda ya gana da masana'antu matsayin a gida da kuma waje. Samfurin ya wuce hanyoyin bincike sama da 200 don sarrafa ingancin samfurin.

"Kada ku bari bututun ƙarfe mara inganci ya shiga kasuwa".

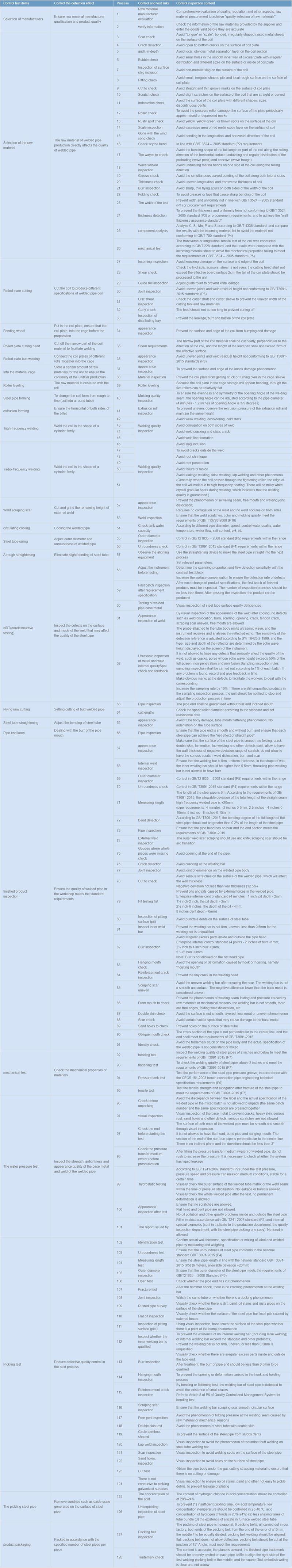

| Sarrafa abubuwan gwaji | Sarrafa tasirin ganowa | Tsari | Sarrafa da gwajin hanyoyin haɗin gwiwa | Sarrafa abun ciki dubawa |

| Zaɓin masana'antun | Tabbatar da cancantar masana'anta da ingancin samfur | 1 | Ƙimar masana'anta danye | Cikakken kimantawa na inganci, suna da sauran al'amura, siyan kayan albarkatun kasa don cimma "zabin ingancin albarkatun kasa" |

| 2 | tabbatar da bayanin | Bincika bayanan albarkatun da mai kaya ya bayar kuma shigar da farfajiyar kaya kafin su kasance daidai | ||

| Zaɓin albarkatun ƙasa | Abubuwan da ake amfani da su na samar da bututun da aka ƙera kai tsaye suna shafar ingancin bututu mai walda | 3 | Duban tabo | Guji "harshe" ko "ma'auni", masu ɗaure, zanen ƙarfe waɗanda aka ɗaga ba bisa ka'ida ba a saman nada |

| 4 | Gane fashewa | Guji buɗaɗɗen faɗuwar ƙasa a saman farantin nada | ||

| 5 | duba-in-zurfin | Guji na gida, bayyanannen layin rabuwa na ƙarfe akan sashin nada | ||

| 6 | Duban kumfa | A guji ƙananan ramuka a cikin santsin bangon ciki na farantin madauwari tare da rarraba mara daidaituwa da girma dabam-dabam akan saman ko cikin farantin nada | ||

| 7 | Dubawa na haɗe slag | Ka guje wa slag mara ƙarfe a saman nada | ||

| 8 | Binciken rami | A guji ƙananan ramuka masu siffa marasa tsari da ƙaƙƙarfan saman ƙasa a saman farantin murɗa | ||

| 9 | Yanke don dubawa | A guji madaidaiciya da siraran tsagi a saman farantin murɗa | ||

| 10 | Duban zare | Ka guje wa ƴan ƙazanta a saman nada wanda yake madaidaiciya ko lanƙwasa | ||

| 11 | Duban shiga | Kauce wa saman farantin nada tare da siffofi daban-daban, masu girma dabam, katsewar haƙora | ||

| 12 | Duban abin nadi | Don guje wa lalacewar abin nadi na matsin lamba, saman farantin lokaci-lokaci yana bayyana alamun dagawa ko tawayar | ||

| 13 | Tsatsa tabo duba | A guji rawaya, rawaya-kore, ko launin ruwan kasa a saman nada | ||

| 14 | Binciken sikelin | Kauce wa wuce gona da iri na jan karfe oxide Layer a saman nada | ||

| 15 | Ya tafi tare da duba waƙar iska | Guji lankwasawa a tsaye da kuma a kwance na nada | ||

| 16 | Duba lankwasa scythe | Daidai da GB/T 3524 -- 2005 daidaitattun buƙatun (P2). | ||

| 17 | Taguwar ruwa don dubawa | Guji siffar lanƙwasawa na cikakken tsayi ko ɓangaren coil ɗin tare da jujjuyawar saman saman kwancen da ba a kwance ba da kuma rarrabawar yau da kullun na mai fitowa (kololuwar igiyar ruwa) da maƙarƙashiya (Trough trough) | ||

| 18 | Kalaman alagammana dubawa | Guji lankwasawa mara nauyi a gefe ɗaya na nada tare da mirgina | ||

| 19 | Binciken tsagi | A guji lanƙwasa mai lanƙwasa lokaci guda na coil tare da bangarorin biyu na gefe | ||

| 20 | Duban kauri | Guji mara daidaituwa a tsayi da kauri na nada | ||

| 21 | Burr dubawa | Kauce wa kaifi, siraran tashi masu tashi a ɓangarorin biyu na faɗin nada | ||

| 22 | Duban naɗewa | Don guje wa murƙushewa ko cinya wanda ke haifar da lanƙwasawa mai kaifi na nada | ||

| 23 | Faɗin gwajin | Hana nisa da daidaituwa ba daidai da GB/T 3524 -- 2005 misali (P4) ko buƙatun siyayya | ||

| 24 | gano kauri | Don hana kauri da daidaito daga rashin dacewa da GB/T 3524 -- 2005 misali (P3) ko buƙatun sayayya, da kuma cimma "ma'aunin tabbacin kauri na bango" | ||

| 25 | bangaren bincike | Yi nazarin C, Si, Mn, P da S bisa ga ma'aunin GB/T 4336, kuma kwatanta sakamakon da jerin abubuwan da ke shigowa don guje wa abubuwan da ba su dace da ma'aunin GB/T 700 (P4) ba. | ||

| 26 | inji gwajin | An gudanar da gwajin juzu'i ko a tsaye na nada bisa ga ma'aunin GB/T 228, kuma an kwatanta sakamakon da takardar abu mai shigowa don guje wa kaddarorin injinan gaza cika buƙatun GB/T 3524 -- 2005 misali (P5). | ||

| Yanke farantin karfe | Yanke coil ɗin don samar da ƙayyadaddun ƙayyadaddun ƙayyadaddun bututun welded | 27 | Dubawa mai shigowa | Ka guji ƙwanƙwasa lalacewa a saman da gefen nada |

| 28 | Duban shear | Bincika almakashi na na'ura mai aiki da karfin ruwa, shear ba ko da ba, yankan kai ba zai wuce ingantaccen allon allon 2cm ba, ya kamata a sarrafa wutsiya farantin nada zuwa naúrar. | ||

| 29 | Jagorar lissafin dubawa | Daidaita abin nadi don hana zubar wuka | ||

| 30 | Binciken haɗin gwiwa | Guji rashin daidaituwa tsakanin haɗin gwiwa da tsayin da aka yi amfani da su ba tare da bin ka'idodin GB/T3091-2015 ba (P8) | ||

| 31 | Binciken tsagewar diski | Bincika sandar abin yanka da hannun riga don hana rashin daidaituwa nisa na kayan aikin yankan da albarkatun ƙasa | ||

| 32 | dubawa mai lanƙwasa | Kada ciyarwar ta yi tsayi da yawa don hana murƙushewa | ||

| 33 | Duban tiren rarrabawa | Hana yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsan yatsa, da bugu da buckle na farantin karfe | ||

| Dabarun ciyarwa | Saka a cikin kwanon rufi, tabbatar da cewa farantin karfe, a cikin keji kafin shiri | 34 | duban gani | Hana saman da gefen nada daga karo da lalacewa |

| Birgima farantin yankan kai | Yanke kunkuntar ɓangaren kayan coil don sauƙaƙe walda | 35 | Abubuwan buƙatu mai ƙarfi | Za a yanke kunkuntar ɓangaren kayan naɗa da kyau, daidai gwargwado zuwa jagorar coil, kuma tsawon ɓangaren jagorar ba zai wuce 2cm na ingantaccen farfajiyar ba. |

| Nadi farantin gindi walda | Haɗa faranti na nada daban-daban tare a cikin kejin | 36 | duban gani | Guji rashin daidaituwa tsakanin haɗin gwiwa da tsayin da aka yi amfani da su ba tare da bin ka'idodin GB/T3091-2015 ba (P8) |

| A cikin kejin kayan | Ajiye takamaiman adadin albarkatun ƙasa don naúrar don tabbatar da ci gaba da samar da motar naúrar | 37 | duban gani | Don hana saman da gefen abin da ke lalata ƙwanƙwasa |

| 38 | Binciken kayan aiki | Hana farantin coil daga makale ko juyawa a hannun keji | ||

| Matsayin abin nadi | Danyen kayan yana tsakiya tare da nadi | 39 | Matsayin abin nadi | Domin farantin nada a cikin keji ajiya zai bayyana lankwasawa, ta cikin biyar rollers iya zama in mun gwada da lebur |

| Karfe bututu kafa | Don canza nau'in coil daga m zuwa lafiya (naɗa a cikin bututu mai zagaye) | 40 | Molding ingancin dubawa | Don tabbatar da daidaito da daidaito na kusurwar buɗewa na kabu na walda, ana iya daidaita kusurwar buɗewa bisa ga diamita na bututu. (minti 4 - inci 1.2 na kusurwar buɗewa shine digiri 3-5) |

| extrusion forming | Tabbatar da a kwance ɓangarorin biyu na billet | 41 | Extrusion roll dubawa | Don hana rashin daidaituwa, lura da matsa lamba na extrusion roll kuma kula da tsayi iri ɗaya |

| high-mita waldi | Weld nada a siffar silinda da ƙarfi | 42 | Welding ingancin dubawa | Guji rauni mai walƙiya, lalata, tari mai sanyi |

| 43 | Guji corrugation a bangarorin biyu na weld | |||

| 44 | Guji tsagewar walda da tsagewar tsaye | |||

| 45 | Guji samuwar layin walda | |||

| waldi mai mitar rediyo | Weld nada a siffar silinda da ƙarfi | 46 | Welding ingancin dubawa | Guji haɗawa da slag |

| 47 | Don guje wa fasa a waje da walda | |||

| 48 | Guji raguwar tushen tushe | |||

| 49 | Guji shigar tushen | |||

| 50 | Guji gazawar haɗuwa | |||

| 51 | Guji walda mai yabo, waldar karya, waldar cinya da sauran abubuwan mamaki. (Gaba ɗaya, lokacin da na'urar ta ratsa ta cikin abin nadi mai ɗaukar nauyi, gefen coil ɗin zai narke saboda yawan dumama. Za a sami walƙiya mai farin kristal granular a lokacin walda, wanda ke nuna cewa an tabbatar da ingancin walda.) | |||

| Weld scraping tabo | Yanke da niƙa sauran tsawo na waje weld | 52 | duban gani | Hana abin da ya faru na swiveling dinki, free baki da waldi hadin gwiwa dislocation; Bukatar babu corrugation na weld kuma babu weld nodules a garesu. |

| 53 | Weld dubawa | Tabbatar cewa tarkacen weld, launi da ingancin gyare-gyare sun cika buƙatun GB/T13793-2008 (P10) | ||

| sanyaya mai yawo | Sanyaya bututun welded | 54 | Duba karfin ruwa na tanki | Dangane da diamita daban-daban na bututu, saurin, sarrafa ingancin ruwa, zafin ruwa, kwararar ruwa, abun ciki na gishiri, pH, da sauransu |

| Girman bututun ƙarfe | Daidaita diamita na waje da rashin zagaye na bututun welded | 55 | Duban diamita na waje | Sarrafa a cikin GB/T21835 -- 2008 daidaitattun buƙatun (P5) tsakanin kewayon |

| 56 | Duban rashin daidaituwa | Sarrafa a cikin GB/T3091-2015 daidaitattun buƙatun (P4) a cikin kewayon | ||

| A m mikewa | Kawar da ɗan lankwasa bututun ƙarfe | 57 | Kula da kayan aikin daidaitawa | Yi amfani da na'urar daidaitawa don sanya bututun ƙarfe madaidaiciya zuwa tsari na gaba |

| NDT (gwajin da ba ya lalacewa) | Bincika lahani a saman da ciki na walda wanda zai iya shafar ingancin bututun ƙarfe | 58 | Daidaita kayan aiki kafin gwaji | Saita sigogi masu dacewa; Ƙayyade ma'auni na dubawa da ƙwarewar gano aibi tare da shingen gwajin bambanci; Ƙara diyya ta sama don tabbatar da ƙimar gano lahani |

| 59 | Binciken rukuni na farko bayan ƙayyadaddun canji | Bayan kowane canji na ƙayyadaddun samfur, dole ne a duba rukunin farko na samfuran da aka gama. Yawan rassan dubawa bai kamata ya zama ƙasa da uku ba. Bayan wucewa dubawa, ana iya samar da samfurin | ||

| 60 | Gwajin welded bututu tushe karfe | Duban gani na karfe tube surface ingancin kasawa | ||

| 61 | Duban bayyanar weld | Ta hanyar dubawa na gani na bayyanar walda bayan sanyaya, ba a ba da lahani irin su waldawa, ƙonewa, tabo, buɗewa, tsagewa, tsagewar tendon, tabo mara kyau, baki kyauta an yarda. | ||

| 62 | Ultrasonic dubawa na karfe da weld ciki qualitySpot rajistan shiga da feedback | Binciken da aka haɗe zuwa jikin bututu yana fitar da igiyar ruwa ta ultrasonic, kuma kayan aikin yana karɓa da kuma nazarin amsawar da aka nuna. Ana daidaita ma'anar ma'anar ganowa bisa ga SY/T6423.2-1999, kuma nau'in, girman da zurfin mai nuna an ƙaddara ta hanyar tsayin motsin amsawa da aka nuna akan allon kayan aiki. Ba a yarda a sami wani lahani da ke da matukar tasiri ga ingancin walda, irin su fashe, pores wanda tsayin raƙuman sauti ya wuce 50% na cikakken allo, rashin shiga da rashin haɗin kai. Dokokin dubawa na samfur: za a gudanar da gwajin samfurin bisa ga 1% na kowane tsari. Idan an sami wata matsala, yi rikodin kuma ba da amsa cikin lokaci. Yi alama a bayyane akan lahani don sauƙaƙe ma'aikata don magance daidai; Ƙara yawan samfurin da kashi 10%. Idan har yanzu akwai samfuran da ba su cancanta ba a cikin tsarin binciken samfur, yakamata a sanar da rukunin don dakatar da daidaita tsarin samarwa cikin lokaci. | ||

| Yanke gani mai tashi | Saitin yankan butt-welded bututu | 63 | Binciken bututu | Za a tabbatar da ƙarshen bututu ba tare da ƙonawa da karkata baki ba |

| 64 | yanke tsayi | Bincika diamita na abin nadi na sauri bisa ga ma'auni kuma saita bayanai masu ma'ana | ||

| Karfe bututu madaidaiciya | Daidaita lankwasawa na karfe bututu | 65 | duban gani | Ka guje wa lalacewar jikin bututu, bututu bakin abu mai karkatarwa; Babu shiga a saman bututu |

| Cire ƙarshen bututu | Magance burar bakin bututu | 66 | Binciken bututu | Tabbatar cewa ƙarshen bututu yana da santsi kuma ba tare da burar ba, kuma tabbatar da cewa kowane bututun ƙarfe zai iya cimma "tasirin net na madaidaiciyar bututu". |

| gama samfurin dubawa | Tabbatar da ingancin bututun welded a cikin bitar ya cika daidaitattun buƙatun | 67 | duban gani | Tabbatar cewa surface na karfe bututu ne santsi, babu nadawa, crack, biyu fata, lamination, cinya waldi da sauran lahani wanzu, ba da damar samun bango kauri na korau karkata kewayon karce, kar a yarda a yi da tsanani karce, weld dislocation, ƙone da tabo. |

| 68 | Duban walda na ciki | Tabbatar cewa sandar walda ta tsaya tsayin daka, kauri iri ɗaya, a cikin sigar waya, sandar walda ta ciki yakamata ta zama sama da 0.5mm, ba a ba da izinin shingen walda ba tare da burar ba. | ||

| 69 | Duban diamita na waje | Sarrafa a cikin GB/T21835 -- 2008 daidaitattun buƙatun (P5) tsakanin kewayon | ||

| 70 | Duban rashin daidaituwa | Sarrafa a cikin GB/T3091-2015 daidaitattun buƙatun (P4) a cikin kewayon | ||

| 71 | Tsawon tsayi | Tsawon bututun karfe shine 6m. Dangane da buƙatun GB / T3091-2015, dacewar ƙetare jimlar jimlar madaidaiciyar bututun welded ɗin madaidaiciyar bututu shine + 20mm. (Bukatun bututu: 4 minutes - 2 inci 0-5mm, 2.5 inci - 4 inci 0-10mm, 5 inci - 8 inci 0-15mm) | ||

| 72 | Lanƙwasa ganowa | Dangane da GB / T3091-2015, matakin lanƙwasawa na cikakken tsayin bututun ƙarfe bai kamata ya fi 0.2% na tsawon bututun ƙarfe ba. | ||

| 73 | Binciken bututu | Tabbatar cewa shugaban bututu ba shi da burr kuma sashin ƙarshen ya cika bukatun GB / T3091-2015 | ||

| 74 | Binciken walda na waje | Ya kamata a yi amfani da wukar baka na waje, tabo ya zama canjin baka | ||

| 75 | Gouges inda gabaɗayan guntuwa suka ɓace rajistan | Ka guji buɗewa a ƙarshen bututu | ||

| 76 | Gane fashewa | Guji fashewa a sandar walda | ||

| 77 | Binciken haɗin gwiwa | Guji al'amarin haɗin gwiwa a jikin bututun welded | ||

| 78 | Yanke don dubawa | Ka guje wa ɓarna mai tsanani a saman bututun welded, wanda zai shafi kaurin bango. Bambanci mara kyau ba kasa da kauri ba (12.5%) | ||

| 79 | Gwajin rami flat | Hana ramuka da ramukan da sojojin waje ke haifarwa a cikin bututun welded. Matsayin kulawa na cikin gida na kasuwanci (minti 4 - inch 1, zurfin rami <2mm; 1¼ inch-2 inch, zurfin rami <3mm; 2½ inch-6 inci, zurfin rami <4mm; 8 inci zurfin haƙora <6mm) | ||

| 80 | Duban saman rami (rami) | Kauce wa ƙugiya a saman bututun ƙarfe | ||

| 81 | Duba mashaya weld na ciki | Hana sandar walda ba ta da ƙarfi, rashin daidaituwa, ƙasa da 0.5mm don sandar walda ba ta cancanta ba. | ||

| 82 | Burr dubawa | Ka guje wa ɓarna da ba daidai ba a ciki da wajen kan bututun. Matsayin kulawar cikin gida na kasuwanci (maki 4 - inci 2 na burr <1mm; 2½ inch zuwa 4 inch burr <2mm; 5 "- 8" buro <3mm. Lura: Ba a yarda Burr akan bututun kai. | ||

| 83 | Duban baki | A guji budewa ko nakasar da ƙugiya ko ɗagawa ke haifarwa, wato "bakin ɗagawa" | ||

| 84 | Ƙarfafa fashewar dubawa | Hana ɗan ƙaramin tsagewa a cikin ƙwanƙwasa walda | ||

| 85 | Tabo mara daidaituwa | Guji madaidaicin sandar walda bayan goge tabo. Wurin waldawa ba shimfidar baka bane santsi. Bambanci mara kyau ƙasa da tushe karfe ana la'akari da m | ||

| 86 | Daga baki don dubawa | Hana sabon abu na walƙiya kabu nadawa da matsa lamba lalacewa ta hanyar albarkatun kasa ko inji dalilai, walda bar ba santsi, akwai free gefuna, nadawa walda dislocation, da dai sauransu | ||

| 87 | Duban fata sau biyu | Ka guje wa saman ba santsi, lebur, ƙarancin nama ko wani abu mara daidaituwa ba | ||

| 88 | Duban tabo | Ka guje wa tabo mai siyar da ƙasa wanda zai iya haifar da lalacewa ga ƙarfen tushe | ||

| 89 | Ramin yashi don dubawa | Hana ramuka a saman bututun ƙarfe | ||

| 90 | Duban bakin da ba a so | Sashin giciye na bututu ba daidai ba ne zuwa layin tsakiya, kuma ƙarshen zai cika bukatun GB / T3091-2015. | ||

| 91 | Duban mutum | Guji alamar kasuwancin da ke makale a jikin bututu kuma ainihin ƙayyadaddun bututun da aka yi masa ba daidai ba ne ko gauraye | ||

| inji gwajin | Duba kayan aikin injiniya na kayan | 92 | lankwasawa gwajin | Bincika ingancin walda na bututun ƙarfe na inci 2 da ƙasa don saduwa da buƙatun GB/T3091-2015 (P7) |

| 93 | gwanjon lallashi | Don duba waldi ingancin karfe bututu sama da 2 inci da kuma saduwa da bukatun GB / T3091-2015 (P7) | ||

| 94 | Gwajin tankin matsi | Gwada aikin matsi na bututun ƙarfe, daidai da CECS 151-2003 haɗin haɗin bututun injiniyan fasaha na ƙayyadaddun buƙatun (P9) | ||

| 95 | tensile gwajin | Gwada ƙarfin ƙarfi da haɓakawa bayan karyewar bututun ƙarfe don saduwa da buƙatun GB/T3091-2015 (P7) | ||

| Gwajin matsa lamba na ruwa | Bincika ƙarfi, rashin iska da ingancin bayyanar ƙarfen tushe da weld na bututun welded | 96 | Duba kafin a kwashe kaya | Guji rashin daidaituwa tsakanin lakabin da ainihin ƙayyadaddun bututun da aka yi masa walda ko kuma ba a ba da izinin buɗe kayan da aka gauraya ba (lambar batch iri ɗaya da ƙayyadaddun ƙayyadaddun abu ɗaya ana danna tare. |

| 97 | dubawa na gani | Duban gani na karfen tushe don hana fasa, fata mai nauyi, tsatsa mai tsanani, ramukan yashi da sauran lahani, ba a yarda da karce mai tsanani ba. | ||

| 97 | Duba ƙarshen kafin fara gwajin | Dole ne saman bangarorin biyu na bututun da aka welded ya zama santsi da santsi ta hanyar dubawa na gani. Ba a yarda a sami kai mai lebur, tanƙwara bututu da bakin rataye ba. Sashin ƙarshen bututun da ba burr ba yana tsaye zuwa tsakiyar layin. Babu jirgin sama mai karkata kuma ya kamata karkacewar ya zama ƙasa da 3° | ||

| 98 | Duba matsakaicin matsa lamba (ruwa) kafin matsa lamba | Bayan cika matsakaicin matsakaicin matsa lamba (ruwa) na bututu mai walda, kada ku yi sauri don ƙara matsa lamba. Wajibi ne a bincika ko tsarin yana da ɗigon ruwa | ||

| 99 | gwajin hydrostatic | Dangane da ma'aunin GB/T241-2007 (P2) a ƙarƙashin gwajin gwajin, saurin matsa lamba da yanayin watsa matsa lamba, barga na ɗan lokaci. Duba a gani na waje na matrix bututu mai walda ko kabu na walda a cikin lokacin daidaitawar matsi. Ba a yarda yayyo ko fashe ba. Duba da gani gabaɗayan bututun welded bayan gwajin, ba a yarda nakasu na dindindin ba | ||

| 100 | Duban bayyanar bayan gwaji | Tabbatar cewa ba a ba da izini ba; Ba a yarda da kai mai lebur da bututu mai lankwasa ba. Babu gurbataccen mai da sauran matsalolin ingancin ciki da wajen bututun karfe | ||

| 101 | Rahoton da ya fitar | Cika cikin tsananin aiki tare da GB / T241-2007 (P2) da misalai na ciki na ciki (sashen motsa jiki na ciki (sashen Tarihi na Siyarwa, tare da Pipe Cokali na Kwafi ɗaya). Ba a yarda da zamba | ||

| Gwajin pickling | Rage ƙarancin kulawar inganci a cikin tsari na gaba | 102 | Gwajin tantancewa | Tabbatar da ainihin kaurin bango, ƙayyadaddun ƙayyadaddun bayanai ko gaurayawan lakabi da bututu mai walda ta hanyar aunawa da aunawa |

| 103 | Gwajin rashin daidaituwa | Tabbatar cewa rashin daidaituwa na bututun ƙarfe ya dace da daidaitattun GB/T 3091-2015 (P4) | ||

| 104 | Gwajin tsayin awo | Tabbatar da karfe bututu tsawon a layi tare da kasa misali GB/T 3091-2015 (P5) (6 mita, halatta sabawa +20mm) | ||

| 105 | Duban diamita na waje | Tabbatar cewa diamita na waje na bututun ƙarfe ya dace da bukatun GB/T21835 -- 2008 Standard (P5) | ||

| 106 | Bude gwaji | Bincika ko ƙarshen bututun ya yanke sabon abu | ||

| 107 | Gwajin karaya | Bayan girgizar guduma, babu wani abin fashewa a sandar walda | ||

| 108 | Binciken haɗin gwiwa | Kalli bututu guda ɗaya akan ko akwai abin da ya faru na docking | ||

| 109 | Rusted bututu binciken | Duba ko a gani ko akwai datti, fenti, tabon mai da kuma bututu masu tsatsa a saman bututun ƙarfe | ||

| 110 | Lebur rami duba | Bincika gani ko saman bututun ƙarfe yana da ramukan gida wanda sojojin waje suka haifar | ||

| 111 | Duban saman rami (ramuka) | Yin amfani da dubawa na gani, hannu ya taɓa saman bututun ƙarfe ko akwai wurin abin da ya faru. | ||

| 112 | Duba ko sandar walda ta ciki ta cancanta | Don hana wanzuwar babu sandar walda ta ciki (ciki har da waldar ƙarya) ko mashaya walda ta ciki da ta wuce misali da sauran matsalolin; Hana sandar walda ba ta da ƙarfi, rashin daidaituwa, ko ƙasa da 0.5mm bai cancanta ba | ||

| 113 | Burr dubawa | Bincika gani ko akwai ɓangarorin da ba su dace ba a ciki da wajen ƙarshen bututu. Bayan magani, burr na ƙarshen bututu ya kamata ya zama ƙasa da 0.5mm don cancanta | ||

| 114 | Rataye baki dubawa | Don hana buɗewa ko nakasar da ke haifarwa a cikin ƙugiya da haɓakawa | ||

| 115 | Ƙarfafa fashewar dubawa | Ta hanyar lankwasawa ko gwadawa, ana gano sandar walda ta bututun ƙarfe don guje wa wanzuwar ƙananan fasa. Koma zuwa Mataki na 8 na P6 na Tsarin Kula da Inganci da Tsarin Gudanarwa don gwajin lankwasawa | ||

| 116 | Duban tabo | Tabbatar cewa sandar walda ta goge tabo mai santsi, saman madauwari | ||

| 117 | Duba tashar jiragen ruwa kyauta | Guji al'amarin na nadawa matsa lamba a kabu waldi lalacewa ta hanyar danyen abu ko inji dalilai. | ||

| 118 | Gwajin fata sau biyu | Kauce wa lamarin bututun ƙarfe tare da fata biyu | ||

| 119 | Da'irar bamboo mai siffa | Don hana saman bututun ƙarfe daga ɓacin rai | ||

| 120 | Duban weld na cinya | Duban gani don guje wa abin da ya faru na sake walda mara nauyi akan sandar bututun walda. | ||

| 121 | Duban tabo | Duban gani don guje wa wuraren walda a saman bututun ƙarfe | ||

| 122 | Ramin yashi, dubawa | Duban gani don guje wa ramuka a saman bututun ƙarfe | ||

| 123 | Yanke gwaji | Sami jikin bututun da ke ƙarƙashin abin da ake yankan iskar gas don tabbatar da cewa babu yanke ko lalacewa | ||

| 124 | Babu dacewa ga pickling galvanized sundries | Duban gani don tabbatar da babu tabon mai, fenti da sauran tarkace marasa sauƙi, don hana zubar plating. | ||

| The pickling karfe bututu | Cire abubuwa daban-daban kamar sikelin oxide da aka samar akan saman bututun ƙarfe | 125 | Matsakaicin acid | Ya kamata a sarrafa abun ciki na hydrogen chloride a cikin tattarawar acid a 20% -24% |

| 126 | Underpickling dubawa na karfe bututu | Don hana (1) rashin isasshen lokacin pickling, low acid zafin jiki, low taro (zazzabi ya kamata a sarrafa a 25-40 ℃, acid taro na hydrogen chloride ne 20% -24%) (2) kasa girgiza sau na tube dam (3) kasancewar silicate a cikin tanderun welded karfe tube. | ||

| samfur marufi | Cushe daidai da ƙayyadadden adadin bututun ƙarfe a kowane yanki | 127 | Duban bel ɗin shiryawa | A marufi na karfe bututu ne hexagonal, 6 shiryawa bel, duk za'ayi a cikin mu factory, duka biyu iyakar shiryawa bel daga karshen kuskure na ± 10mm, tsakiyar 4 da za a daidai rarraba, shiryawa bel waldi ya kamata a daidaitacce, lebur, shiryawa bel ba ya ƙyale deflection, shiryawa bel ya kamata a yanke a junction na 45 ° A junction, dole ne saduwa da bukatun 45. |

| 128 | Duba alamar kasuwanci | Abin da ke ciki daidai ne, jirgin yana sama, alamar kasuwancin da aka gama ya kamata a liƙa da kyau a kan kowane bututun bututu don daidaita gefen dama na bel ɗin haɗaɗɗen walda na farko a tsakiya, kuma tushen rubutun Ted na ado a bayyane yake ba tambaya ba. |