YuantaiDerunsquare square raj muaj ntau tshaj 63 patents, uas ua tau raws li cov qauv kev lag luam hauv tsev thiab txawv teb chaws. Cov khoom lag luam tau dhau ntau tshaj 200 qhov kev tshuaj ntsuam xyuas los tswj cov khoom zoo.

"Nco tsis txhob cia cov yeeb nkab tsis tsim nyog rau hauv kev ua lag luam".

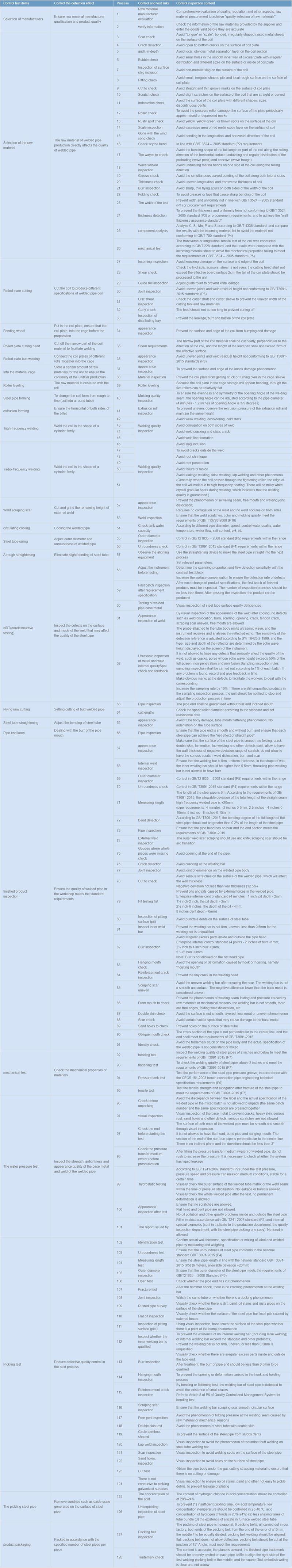

| Tswj cov khoom kuaj | Tswj xyuas qhov cuam tshuam | Txheej txheem | Tswj thiab sim txuas | Tswj xyuas cov ntsiab lus |

| Kev xaiv cov neeg tsim khoom | Xyuas kom cov neeg tsim khoom tsim khoom tsim nyog thiab cov khoom zoo | 1 | Kev ntsuam xyuas cov khoom siv raw khoom | Kev ntsuam xyuas kev ua tau zoo, lub koob npe nrov thiab lwm yam, kev yuav khoom raw khoom kom ua tiav "kev xaiv zoo ntawm cov khoom siv raw" |

| 2 | txheeb xyuas cov ntaub ntawv | Tshawb xyuas cov ntaub ntawv ntawm cov ntaub ntawv raw khoom muab los ntawm tus neeg muag khoom thiab nkag mus rau hauv cov khoom vaj khoom ua ntej lawv raug | ||

| Kev xaiv cov khoom siv raw | Cov khoom siv raw ntawm cov yeeb nkab welded ncaj qha cuam tshuam rau qhov zoo ntawm cov yeeb nkab welded | 3 | Khawb kos | Tsis txhob "tus nplaig" los yog "scale", sib koom ua ke, irregularly zoo li tus hlau los xij ntawm qhov chaw ntawm lub kauj. |

| 4 | Kev kuaj pom tawg | Tsis txhob qhib qhov taub hauv qab cov kab nrib pleb ntawm qhov chaw coil phaj | ||

| 5 | audit-in-depth | Tsis txhob sib cais hauv zos, pom tseeb hlau txheej ntawm lub kauj ntu | ||

| 6 | Bubble check | Tsis txhob muaj qhov me me nyob rau hauv cov phab ntsa du ntawm lub voj voog nrog kev faib tawm tsis tu ncua thiab qhov sib txawv ntawm qhov chaw los yog sab hauv ntawm coil phaj | ||

| 7 | Kev tshuaj xyuas ntawm qhov chaw slag suav nrog | Tsis txhob siv cov slag uas tsis yog xim hlau rau ntawm qhov chaw ntawm lub kauj | ||

| 8 | Pitting check | Tsis txhob me me, tsis sib xws pits thiab hauv zos ntxhib saum npoo ntawm coil phaj | ||

| 9 | Txiav mus kuaj | Tsis txhob ncaj thiab nyias groove cim rau ntawm qhov chaw ntawm coil phaj | ||

| 10 | Kos kos | Tsis txhob khawb me ntsis rau ntawm qhov chaw ntawm lub kauj uas ncaj los yog nkhaus | ||

| 11 | Indentation check | Tsis txhob ntog ntawm lub phaj coil nrog cov duab sib txawv, qhov ntau thiab tsawg, cov dents tsis tu ncua | ||

| 12 | Roller check | Txhawm rau kom tsis txhob muaj kev puas tsuaj rau cov menyuam, qhov chaw ntawm lub phaj ib ntus yuav tshwm sim los yog muaj kev ntxhov siab | ||

| 13 | Rusty spot check | Tsis txhob daj, daj-ntsuab, los yog xim av me ntsis ntawm qhov chaw ntawm lub kauj | ||

| 14 | Ntsuas ntsuas | Tsis txhob ntau dhau ntawm cov xim liab oxide txheej nyob rau saum npoo ntawm coil | ||

| 15 | Mus nrog cua zaj nkauj check | Tsis txhob khoov nyob rau hauv longitudinal thiab kab rov tav kev taw qhia ntawm lub kauj | ||

| 16 | Tshawb xyuas scythe khoov | Raws li GB / T 3524 - 2005 tus qauv (P2). | ||

| 17 | Cov nthwv dej mus kuaj | Zam kom tsis txhob muaj qhov khoov ntawm qhov ntev lossis ib feem ntawm lub kauj raws li cov kev taw qhia dov ntawm kab rov tav nto undulating thiab tsis tu ncua ntawm cov protruding (yoj lub ncov) thiab concave (yoj trough) | ||

| 18 | Wave wrinkle tshuaj xyuas | Tsis txhob undulating marina khoov ntawm ib sab ntawm lub kauj raws txoj kev dov | ||

| 19 | Groove check | Tsis txhob sib npaug ntawm qhov nkhaus nkhaus ntawm lub kauj raws ob sab sab | ||

| 20 | Thickness check | Tsis txhob sib npaug longitudinal thiab transverse thickness ntawm kauj | ||

| 21 | Burr kev soj ntsuam | Tsis txhob ntse, nyias ya spurs ntawm ob sab ntawm qhov dav ntawm lub kauj | ||

| 22 | Folding check | Kom tsis txhob creases los yog laps uas ua rau ntse bending ntawm lub kauj | ||

| 23 | Qhov dav ntawm qhov kev xeem | Tiv thaiv qhov dav thiab tsis sib xws tsis raws li GB / T 3524 - 2005 tus qauv (P4) lossis kev yuav khoom | ||

| 24 | nrhiav kom pom thickness | Txhawm rau tiv thaiv qhov tuab thiab tsis sib xws los ntawm kev tsis ua raws li GB / T 3524 - 2005 tus qauv (P3) lossis kev yuav khoom yuav tsum tau ua, thiab ua kom tau raws li "cov qauv kev ruaj ntseg phab ntsa" | ||

| 25 | kev tshuaj ntsuam xyuas | Txheeb xyuas C, Si, Mn, P thiab S raws li GB / T 4336 tus qauv, thiab sib piv cov txiaj ntsig nrog cov khoom xa tuaj kom tsis txhob muaj cov khoom tsis ua raws li GB / T 700 tus qauv (P4) | ||

| 26 | mechanical xeem | Kev ntsuas kev sib hloov lossis longitudinal tensile ntawm lub kauj yog ua raws li GB / T 228 tus qauv, thiab cov txiaj ntsig tau muab piv nrog cov ntaub ntawv nkag los kom tsis txhob muaj cov khoom siv tshuab ua tsis tau raws li qhov yuav tsum tau ua ntawm GB / T 3524 - 2005 tus qauv (P5). | ||

| Rolled phaj txiav | Txiav lub coil los tsim cov kev qhia tshwj xeeb ntawm welded yeeb nkab coil | 27 | Kev tshuaj xyuas tuaj | Tsis txhob cuam tshuam kev puas tsuaj rau ntawm qhov chaw thiab ntug ntawm lub kauj |

| 28 | Shear check | Txheeb xyuas cov txiab txiab, txiav tsis tau txawm tias, lub taub hau txiav yuav tsum tsis pub tshaj 2cm ntawm lub rooj tsavxwm zoo, tus Tsov tus tw ntawm lub phaj phaj yuav tsum tau ua tiav rau chav tsev. | ||

| 29 | Qhia yob tshuaj xyuas | Kho cov lus qhia rau cov menyuam kom tsis txhob muaj riam to | ||

| 30 | Kev tshuaj ntsuam xyuas | Zam kev sib koom ua ke tsis sib xws thiab qhov siab qhov seem uas tsis ua raws li GB / T3091-2015 tus qauv (P8) | ||

| 31 | Disc shear soj ntsuam | Tshawb xyuas lub cutter ncej thiab lub tes tsho cutter kom tiv thaiv qhov tsis sib xws ntawm cov cuab yeej txiav thiab cov khoom siv raw | ||

| 32 | Curly check | Pub yuav tsum tsis txhob ntev dhau los tiv thaiv curling tawm | ||

| 33 | Kev tshuaj xyuas ntawm cov tais ntim khoom | Tiv thaiv kom tsis txhob tawg, burr thiab buckle ntawm coil phaj | ||

| Pub lub log | Muab tso rau hauv lub coil phaj, xyuas kom meej tias lub kauj phaj, rau hauv lub tawb ua ntej kev npaj | 34 | kev tshuaj ntsuam xyuas | Tiv thaiv kom tsis txhob ntog thiab ntug ntawm lub kauj los ntawm kev sib tsoo thiab kev puas tsuaj |

| Rolled phaj txiav taub hau | Txiav tawm qhov nqaim ntawm cov khoom siv coil kom yooj yim vuam | 35 | Shear xav tau | Qhov nqaim ntawm cov khoom siv coil yuav tsum raug txiav kom zoo, nyob rau ntawm qhov kev taw qhia ntawm lub kauj, thiab qhov ntev ntawm cov hlau lead yuav tsum tsis pub tshaj 2cm ntawm qhov zoo. |

| Rolled phaj taub qab vuam | Txuas cov coils ntawm cov yob sib txawv Ua ke rau hauv lub tawb | 36 | kev tshuaj ntsuam xyuas | Zam kev sib koom ua ke tsis sib xws thiab qhov siab qhov seem uas tsis ua raws li GB / T3091-2015 tus qauv (P8) |

| Nyob rau hauv cov khoom tawb | Khaws ib qho nyiaj ntawm cov ntaub ntawv raw rau chav tsev kom ntseeg tau tias qhov txuas ntxiv ntawm unitCar ntau lawm | 37 | kev tshuaj ntsuam xyuas | Txhawm rau tiv thaiv qhov nto thiab ntug ntawm lub khob puas tshwm sim |

| 38 | Kev tshuaj xyuas cov khoom | Tiv thaiv kom lub coil phaj tsis txhob daig lossis tig rau hauv lub tes tsho tawb | ||

| Roller leveling | Cov khoom siv raw yog nruab nrab nrog yob | 39 | Roller leveling | Vim hais tias cov coil phaj nyob rau hauv lub tawb cia yuav tshwm sim dabtsi yog khoov, los ntawm tsib chais yuav ua tau kuj tiaj tus |

| Steel yeeb nkab txoj kev | Hloov daim ntawv coil los ntawm ntxhib mus rau nplua (coil mus rau hauv ib puag ncig lub raj) | 40 | Moulding zoo soj ntsuam | Txhawm rau kom ntseeg tau qhov sib npaug thiab sib luag ntawm qhov qhib lub kaum sab xis ntawm vuam seam, qhib lub kaum sab xis tuaj yeem hloov kho raws li txoj kab uas hla ntawm cov yeeb nkab. (4 feeb - 1.2 ntiv tes qhib lub kaum sab xis yog 3-5 degrees) |

| extrusion txoj kev | Xyuas kom cov kab rov tav ntawm ob sab ntawm lub billet | 41 | Extrusion yob tshuaj xyuas | Txhawm rau tiv thaiv qhov tsis sib xws, saib xyuas qhov extrusion siab ntawm extrusion yob thiab tswj qhov siab tib yam |

| high-frequency vuam | Weld lub kauj nyob rau hauv cov duab ntawm ib lub tog raj kheej khov kho | 42 | Welding zoo soj ntsuam | Tsis txhob qaug zog welding, desoldering, txias pawg |

| 43 | Tsis txhob corrugation ntawm ob sab ntawm weld | |||

| 44 | Tsis txhob weld cracking thiab zoo li qub tawg | |||

| 45 | Tsis txhob tsim cov kab weld | |||

| xov tooj cua zaus welding | Weld lub kauj nyob rau hauv cov duab ntawm ib lub tog raj kheej khov kho | 46 | Welding zoo soj ntsuam | Tsis txhob suav nrog slag |

| 47 | Txhawm rau kom tsis txhob muaj cov kab nrib pleb sab nraud | |||

| 48 | Tsis txhob muaj lub hauv paus shrinkage | |||

| 49 | Zam kev nkag mus hauv paus | |||

| 50 | Zam kev ua tsis tiav ntawm fusion | |||

| 51 | Tsis txhob welding, cuav vuam, lap vuam thiab lwm yam tshwm sim. (Feem ntau, thaum lub kauj dhau los ntawm cov menyuam zawm, lub npoo ntawm lub kauj yuav yaj vim muaj cua sov ntau zaus. Nws yuav muaj cov kua mis dawb crystal granular spark thaum lub vuam, uas qhia tau hais tias qhov vuam zoo yog lav.) | |||

| Weld scraping caws pliav | Txiav thiab zom qhov seem ntawm qhov siab ntawm sab nraud weld | 52 | kev tshuaj ntsuam xyuas | Tiv thaiv qhov tshwm sim ntawm swiveling seam, dawb lub qhov ncauj thiab vuam sib koom ua ke dislocation; Yuav tsum tsis muaj corrugation ntawm weld thiab tsis muaj weld nodules ntawm ob sab. |

| 53 | Kev tshuaj xyuas Weld | Xyuas kom meej tias cov vuam khawb, xim thiab molding zoo raws li qhov yuav tsum tau ua ntawm GB / T13793-2008 (P10) | ||

| circulating cua txias | Txias lub welded yeeb nkab | 54 | Tshawb xyuas lub tank dej muaj peev xwm | Raws li cov yeeb nkab kab sib txawv, ceev, tswj dej zoo, dej kub, dej ntws, ntsev cov ntsiab lus, pH, thiab lwm yam |

| Hlau tube sizing | Kho sab nraud txoj kab uas hla thiab unroundness ntawm welded yeeb nkab | 55 | Kev soj ntsuam sab nraud | Tswj hauv GB / T21835 - 2008 tus qauv (P5) yuav tsum nyob rau hauv qhov ntau |

| 56 | Unroundness check | Tswj nyob rau hauv GB / T3091-2015 tus qauv (P4) yuav tsum nyob rau hauv ntau yam | ||

| Ib tug ntxhib straightening | Tshem tawm me ntsis dabtsi yog khoov ntawm steel raj | 57 | Saib xyuas cov khoom sib dhos | Siv cov cuab yeej ncaj nraim los ua kom cov yeeb nkab steel ncaj rau hauv cov txheej txheem tom ntej |

| NDT (Nondestructive testing) | Tshawb xyuas qhov tsis xws ntawm qhov chaw thiab sab hauv ntawm qhov vuam uas yuav cuam tshuam rau qhov zoo ntawm cov yeeb nkab steel | 58 | Kho qhov ntsuas ua ntej kuaj | Teem cov tsis muaj feem cuam tshuam; Txiav txim siab qhov kev faib ua scanning thiab qhov tsis txaus ntseeg qhov kev pom zoo nrog qhov sib piv ntsuas ntsuas; Ua kom cov nyiaj them rau saum npoo kom ntseeg tau tias qhov kev kuaj pom ntawm qhov tsis xws luag |

| 59 | Thawj batch tshuaj xyuas tom qab hloov specification | Tom qab txhua qhov kev hloov ntawm cov khoom specifications, thawj batch ntawm cov khoom tiav yuav tsum tau soj ntsuam. Tus naj npawb ntawm cov chaw soj ntsuam yuav tsum tsis pub tsawg tshaj peb. Tom qab dhau qhov kev tshuaj xyuas, cov khoom tuaj yeem tsim tau | ||

| 60 | Kev ntsuam xyuas ntawm welded yeeb nkab puag hlau | Kev kuaj pom ntawm steel tube nto qhov tsis zoo | ||

| 61 | Kev tshuaj ntsuam xyuas ntawm weld | Los ntawm kev tshuaj xyuas qhov pom ntawm qhov pom ntawm qhov vuam tom qab txias, tsis muaj qhov tsis xws luag xws li vuam dislocation, hlawv, caws pliav, qhib, tawg, leeg tawg, khawb caws pliav tsis sib xws, lub qhov ncauj pub dawb | ||

| 62 | Ultrasonic tshuaj xyuas cov hlau thiab vuam sab hauv zooSpot xyuas thiab tawm tswv yim | Qhov kev sojntsuam txuas nrog lub raj lub cev emits ultrasonic nthwv dej, thiab qhov ntsuas tau txais thiab txheeb xyuas cov suab nrov. Lub rhiab heev ntawm kev tshawb nrhiav siv tau raug kho raws li SY / T6423.2-1999, thiab hom, qhov loj thiab qhov tob ntawm lub reflector yog txiav txim los ntawm lub ncha nthwv dej qhov siab pom ntawm qhov screen ntawm lub ntsuas. Nws tsis raug tso cai kom muaj qhov tsis xws luag uas cuam tshuam rau qhov zoo ntawm cov vuam, xws li cov kab nrib pleb, qhov pores uas echo yoj qhov siab tshaj 50% ntawm tag nrho cov kev tshuaj ntsuam, tsis yog-ntev thiab tsis-fusion.Sampling kev soj ntsuam cov cai: sampling soj ntsuam yuav tsum tau ua raws li 1% ntawm txhua batch. Yog tias pom muaj teeb meem, sau thiab muab cov lus teb rau lub sijhawm. Ua kom pom tseeb cov cim ntawm qhov tsis xws luag los pab cov neeg ua haujlwm los daws qhov sib xws; Nce tus nqi piv txwv los ntawm 10%. Yog tias tseem muaj cov khoom lag luam tsis tsim nyog hauv cov txheej txheem kuaj xyuas, chav tsev yuav tsum tau ceeb toom kom nres thiab kho cov txheej txheem tsim khoom raws sijhawm | ||

| Flying saw txiav | Kev txiav cov pob tw-welded yeeb nkab | 63 | Kev tshuaj xyuas yeeb nkab | Cov yeeb nkab kawg yuav tsum tau lav tsis muaj burr thiab inclined lub qhov ncauj |

| 64 | txiav qhov ntev | Txheeb xyuas qhov ceev cov menyuam txoj kab uas hla raws li tus qauv thiab teeb tsa cov ntaub ntawv tsim nyog | ||

| Steel raj straightening | Kho qhov khoov ntawm steel raj | 65 | kev tshuaj ntsuam xyuas | Zam lub cev puas tsuaj, raj lub qhov ncauj flattening tshwm sim; Tsis muaj indentation ntawm lub raj nto |

| Cov yeeb nkab kawg khaws cia | Kev cuam tshuam nrog lub burr ntawm lub qhov ncauj qhov ncauj | 66 | Kev tshuaj xyuas yeeb nkab | Xyuas kom meej tias cov yeeb nkab kawg yog du thiab tsis muaj burr, thiab xyuas kom meej tias txhua cov yeeb nkab steel tuaj yeem ua tiav "cov nyhuv ntawm cov yeeb nkab ncaj". |

| Kev tshuaj xyuas cov khoom tiav | Xyuas kom qhov zoo ntawm welded yeeb nkab nyob rau hauv lub rhiav raws li tus qauv yuav tsum tau | 67 | kev tshuaj ntsuam xyuas | Xyuas kom meej tias qhov saum npoo ntawm cov yeeb nkab steel yog du, tsis muaj folding, tawg, ob daim tawv nqaij, lamination, ncej vuam thiab lwm yam tsis xws luag, tso cai rau kom muaj cov phab ntsa thickness ntawm qhov tsis zoo sib txawv ntawm khawb, tsis txhob cia kom muaj qhov khawb loj, weld dislocation, hlawv thiab caws pliav. |

| 68 | Internal weld soj ntsuam | Xyuas kom meej tias lub vuam bar yog ruaj khov, tsis sib xws thickness, nyob rau hauv cov duab ntawm hlau, lub puab vuam bar yuav tsum siab tshaj 0.5 hli, threading yeeb nkab vuam bar tsis pub kom muaj burr. | ||

| 69 | Kev soj ntsuam sab nraud | Tswj hauv GB / T21835 - 2008 tus qauv (P5) yuav tsum nyob rau hauv qhov ntau | ||

| 70 | Unroundness check | Tswj nyob rau hauv GB / T3091-2015 tus qauv (P4) yuav tsum nyob rau hauv ntau yam | ||

| 71 | Ntsuas qhov ntev | Qhov ntev ntawm cov yeeb nkab steel yog 6m. Raws li qhov yuav tsum tau muaj ntawm GB / T3091-2015, qhov tso cai sib txawv ntawm tag nrho qhov ntev ntawm txoj hlua ncaj ncaj high-frequency welded yeeb nkab yog +20mm. (Cov kav dej yuav tsum muaj: 4 feeb - 2 nti 0-5mm, 2.5 nti - 4 nti 0-10mm, 5 nti - 8 nti 0-15mm) | ||

| 72 | Khoov khoov | Raws li GB / T3091-2015, qhov khoov ntawm qhov ntev ntawm cov yeeb nkab steel yuav tsum tsis txhob ntau tshaj 0.2% ntawm qhov ntev ntawm cov yeeb nkab steel. | ||

| 73 | Kev tshuaj xyuas yeeb nkab | Xyuas kom meej tias lub taub hau yeeb nkab tsis muaj burr thiab qhov kawg seem ua tau raws li qhov yuav tsum tau muaj ntawm GB / T3091-2015 | ||

| 74 | External weld soj ntsuam | Sab nrauv weld caws pliav yuav tsum siv arc riam, scraping caws pliav yuav tsum yog arc hloov | ||

| 75 | Gouges qhov twg tag nrho cov tsis tau kos | Tsis txhob qhib qhov kawg ntawm cov yeeb nkab | ||

| 76 | Kev kuaj pom tawg | Tsis txhob tawg ntawm qhov vuam bar | ||

| 77 | Kev tshuaj ntsuam xyuas | Tsis txhob sib koom ua ke tshwm sim ntawm welded yeeb nkab lub cev | ||

| 78 | Txiav mus kuaj | Tsis txhob khawb loj rau ntawm qhov chaw ntawm cov yeeb nkab welded, uas yuav cuam tshuam rau phab ntsa thickness. Qhov tsis zoo sib txawv tsis tsawg dua phab ntsa thickness (12.5%) | ||

| 79 | Pit test flat | Tiv thaiv cov pits thiab pits tshwm sim los ntawm sab nraud quab yuam hauv cov yeeb nkab welded. Cov txheej txheem tswj kev lag luam sab hauv (4 feeb - 1 nti, qhov tob <2mm; 1¼ nti-2 nti, qhov tob <3mm; 2½ nti-6 nti, qhov tob ntawm lub qhov <4mm; 8 nti dent qhov tob <6mm) | ||

| 80 | Kev soj ntsuam ntawm pitting nto (qhov) | Tsis txhob punctate dents ntawm qhov chaw ntawm lub raj steel | ||

| 81 | Tshawb xyuas sab hauv weld bar | Tiv thaiv qhov vuam bar tsis ruaj, tsis sib xws, tsawg dua 0.5mm rau qhov vuam bar tsis tsim nyog | ||

| 82 | Burr kev soj ntsuam | Tsis txhob muaj qhov tsis sib xws hauv thiab sab nraud ntawm lub taub hau yeeb nkab. Enterprise tswj kev tswj tus qauv (4 ntsiab lus - 2 ntiv tes ntawm burr <1mm; 2½ nti mus rau 4 nti burr <2mm; 5"-8" burr <3mm. Lus Cim: Burr tsis raug tso cai rau ntawm lub net taub hau yeeb nkab. | ||

| 83 | Hanging qhov ncauj kuaj | Tsis txhob qhib lossis deformation tshwm sim los ntawm nuv lossis hoisting, xws li "hoisting qhov ncauj" | ||

| 84 | Reinforcement tawg tshuaj xyuas | Tiv thaiv qhov me me tawg hauv cov hlaws vuam | ||

| 85 | Scraping caws pliav tsis sib xws | Zam qhov tsis sib xws ntawm vuam bar tom qab khawb qhov caws pliav. Lub vuam bar tsis yog ib tug du arc nto. Qhov tsis zoo sib txawv qis dua lub hauv paus hlau yog suav tias yog tsis sib xws | ||

| 86 | Los ntawm qhov ncauj mus kuaj | Tiv thaiv qhov tshwm sim ntawm vuam seam folding thiab siab los ntawm raw cov ntaub ntawv los yog mechanical vim li cas, lub vuam bar tsis du, muaj dawb npoo, folding weld dislocation, thiab lwm yam | ||

| 87 | Muab ob npaug rau daim tawv nqaij | Zam lub ntsej muag tsis du, txheej, cov nqaij tsawg dua los yog qhov tshwm sim tsis sib xws | ||

| 88 | Khawb kos | Tsis txhob ntog qhov chaw uas tuaj yeem ua rau lub hauv paus hlau puas | ||

| 89 | Xuab zeb qhov los xyuas | Tiv thaiv qhov ntawm qhov chaw ntawm lub raj steel | ||

| 90 | Oblique qhov ncauj kos | Qhov hla ntawm cov yeeb nkab tsis yog perpendicular mus rau hauv nruab nrab kab, thiab qhov kawg yuav tsum tau raws li qhov yuav tsum tau ntawm GB / T3091-2015 | ||

| 91 | Kev txheeb xyuas tus kheej | Zam kev lag luam daig ntawm cov yeeb nkab lub cev thiab qhov tseeb tshwj xeeb ntawm cov yeeb nkab welded tsis zoo ib yam lossis sib xyaw | ||

| mechanical xeem | Tshawb xyuas cov khoom siv kho tshuab ntawm cov khoom siv | 92 | khoov kuaj | Tshawb xyuas qhov vuam zoo ntawm cov kav hlau ntawm 2 ntiv tes thiab hauv qab kom tau raws li qhov yuav tsum tau ua ntawm GB / T3091-2015 (P7) |

| 93 | flattening xeem | Txhawm rau txheeb xyuas qhov zoo ntawm cov kav hlau steel saum 2 ntiv tes thiab ua tau raws li qhov xav tau ntawm GB / T3091-2015 (P7) | ||

| 94 | Kev ntsuas siab tank | Ntsuam xyuas qhov ua tau zoo ntawm cov yeeb nkab steel siab zawj, raws li CECS 151-2003 trench txuas yeeb nkab engineering technical specification yuav tsum (P9) | ||

| 95 | tensile xeem | Ntsuas lub zog tensile thiab elongation tom qab tawg ntawm cov yeeb nkab steel kom ua tau raws li qhov yuav tsum tau ua ntawm GB / T3091-2015 (P7) | ||

| Kev ntsuas dej siab | Tshawb xyuas lub zog, airtightness thiab pom zoo ntawm lub hauv paus hlau thiab vuam ntawm cov yeeb nkab welded | 96 | Xyuas ua ntej unpacking | Tsis txhob muaj qhov sib txawv ntawm daim ntawv lo thiab qhov tseeb specification ntawm cov yeeb nkab welded los yog cov khoom sib xyaw tsis raug tso cai kom tsis txhob ntim khoom (tib batch tooj thiab tib cov lus qhia yog nias ua ke |

| 97 | kev tshuaj xyuas qhov muag | Kev kuaj pom ntawm lub hauv paus hlau los tiv thaiv cov kab nrib pleb, tawv tawv, xeb loj, xuab zeb qhov thiab lwm yam tsis xws luag, tsis muaj kev khawb loj. | ||

| 97 | Xyuas qhov kawg ua ntej pib qhov kev xeem | Qhov saum npoo ntawm ob qhov kawg ntawm cov yeeb nkab welded yuav tsum du thiab du los ntawm kev tshuaj xyuas qhov muag. Tsis pub muaj lub taub hau tiaj tus, khoov yeeb nkab thiab dai qhov ncauj. Qhov seem ntawm qhov kawg ntawm cov yeeb nkab uas tsis yog-burr yog perpendicular mus rau hauv nruab nrab kab. Tsis muaj lub dav hlau inclined thiab qhov sib txawv yuav tsum tsawg dua 3 ° | ||

| 98 | Tshawb xyuas qhov hloov pauv nruab nrab (dej) ua ntej lub zog | Tom qab sau lub siab hloov nruab nrab (dej) ntawm cov yeeb nkab welded, tsis txhob maj kom nce siab. Nws yog tsim nyog los xyuas seb lub system puas muaj kua to | ||

| 99 | Kev ntsuam xyuas hydrostatic | Raws li GB / T241-2007 tus qauv (P2) nyob rau hauv kev sim siab, siab ceev thiab siab kis tau tus mob nruab nrab, ruaj khov rau ib lub sijhawm. Saib xyuas sab nrauv ntawm lub welded raj matrix los yog vuam seam nyob rau hauv lub sij hawm ntawm lub siab stabilization. Tsis tso cai los yog tawg. Saib xyuas tag nrho cov yeeb nkab welded tom qab qhov kev sim, tsis muaj kev cuam tshuam mus tas li | ||

| 100 | Kev tshuaj ntsuam xyuas tom qab kuaj | Xyuas kom meej tias tsis muaj khawb raug tso cai; Lub taub hau tiaj tus thiab khoov yeeb nkab tsis raug tso cai. Tsis muaj roj paug thiab lwm yam teeb meem zoo sab hauv thiab sab nraum cov yeeb nkab steel | ||

| 101 | Daim ntawv tshaj tawm los ntawm | Sau rau hauv nruj raws li GB / T241-2007 tus qauv (P2) thiab cov piv txwv tshwj xeeb sab hauv (xa tuaj rau hauv triplicate mus rau lub tuam tsev tsim khoom, lub chaw soj ntsuam zoo, nrog rau cov yeeb nkab steel pickling ib daim ntawv). Tsis pub muaj kev dag ntxias | ||

| Pickling xeem | Txo cov kev tswj tsis zoo hauv cov txheej txheem tom ntej | 102 | Kev kuaj xyuas tus kheej | Paub meej tias cov phab ntsa tuab, qhov tshwj xeeb lossis sib xyaw ntawm daim ntawv lo thiab cov yeeb nkab welded los ntawm kev ntsuas thiab ntsuas |

| 103 | Kev kuaj tsis sib haum | Xyuas kom meej tias qhov tsis sib luag ntawm cov yeeb nkab steel ua raws li lub teb chaws tus qauv GB / T 3091-2015 (P4) | ||

| 104 | Kev ntsuas qhov ntev | Xyuas kom cov yeeb nkab steel ntev raws li lub teb chaws tus qauv GB / T 3091-2015 (P5) (6 meters, tso cai sib txawv + 20mm) | ||

| 105 | Kev soj ntsuam sab nraud | Xyuas kom meej tias sab nraud ntawm cov yeeb nkab steel ua tau raws li qhov yuav tsum tau ua ntawm GB / T21835 - 2008 Standard (P5) | ||

| 106 | Qhib kev xeem | Xyuas seb cov yeeb nkab kawg tau txiav qhov tshwm sim | ||

| 107 | Kev kuaj pob txha | Tom qab lub rauj poob siab, tsis muaj qhov tshwm sim tawg ntawm qhov vuam bar | ||

| 108 | Kev tshuaj ntsuam xyuas | Saib tib lub raj ntawm seb puas muaj qhov tshwm sim docking | ||

| 109 | Rusted yeeb nkab soj ntsuam | Saib xyuas seb puas muaj av, xim, roj stains thiab rusty kav nyob rau saum npoo ntawm cov yeeb nkab steel | ||

| 110 | Kev tshuaj ntsuam xyuas lub tiaj tiaj | Saib xyuas seb qhov chaw ntawm cov yeeb nkab steel puas muaj cov pits hauv zos uas tshwm sim los ntawm kev quab yuam sab nraud | ||

| 111 | Kev soj ntsuam ntawm pitting nto (qhov) | Siv kev tshuaj xyuas qhov muag, tes kov qhov chaw ntawm cov yeeb nkab steel seb puas muaj qhov taw tes ntawm qhov tshwm sim ntawm pob | ||

| 112 | Tshawb xyuas seb lub welding sab hauv puas tsim nyog | Txhawm rau kom tsis txhob muaj qhov tsis muaj vuam bar (nrog rau cov vuam tsis raug) lossis sab hauv vuam bar tshaj tus qauv thiab lwm yam teeb meem; Tiv thaiv qhov vuam bar tsis ruaj khov, tsis sib xws, lossis tsawg dua 0.5 hli yog qhov tsis tsim nyog | ||

| 113 | Burr kev soj ntsuam | Saib xyuas seb puas muaj qhov tsis sib xws hauv thiab sab nraum lub raj kawg. Tom qab kev kho mob, qhov burr ntawm cov yeeb nkab kawg yuav tsum tsawg dua 0.5 hli kom tsim nyog | ||

| 114 | Kev tshuaj xyuas qhov ncauj | Txhawm rau tiv thaiv qhov qhib lossis deformation tshwm sim hauv txoj kev sib tsoo thiab hoisting | ||

| 115 | Reinforcement tawg tshuaj xyuas | Los ntawm dabtsi yog khoov los yog flattening xeem, qhov vuam bar ntawm steel yeeb nkab yog kuaj kom tsis txhob muaj cov kab nrib pleb me me. Xa mus rau Tshooj 8 ntawm P6 ntawm Kev Tswj Xyuas Zoo thiab Kev Tswj Xyuas Txheej Txheem rau kev sim khoov | ||

| 116 | Scraping caws pliav tshuaj xyuas | Xyuas kom meej tias lub vuam bar scraping caws pliav du, ncig nto | ||

| 117 | Kev kuaj xyuas qhov chaw nres nkoj dawb | Tsis txhob muaj qhov tshwm sim ntawm folding siab ntawm vuam seam los ntawm cov khoom siv raw lossis cov khoom siv kho tshuab | ||

| 118 | Ob daim tawv nqaij kuaj | Zam qhov tshwm sim ntawm steel raj nrog ob daim tawv nqaij | ||

| 119 | Lub voj voog xyoob-puab | Txhawm rau tiv thaiv qhov chaw ntawm cov yeeb nkab steel los ntawm slubby dents | ||

| 120 | Lap weld soj ntsuam | Kev soj ntsuam pom pom kom tsis txhob muaj qhov tshwm sim ntawm kev rov ua dua lub pob tw vuam ntawm steel raj vuam bar | ||

| 121 | Kev tshuaj xyuas qhov caws pliav | Kev soj ntsuam pom kom tsis txhob muaj qhov vuam ntawm qhov chaw ntawm cov yeeb nkab steel | ||

| 122 | Xuab zeb qhov, tshuaj xyuas | Kev kuaj pom pom kom tsis txhob muaj qhov nyob ntawm qhov chaw ntawm cov yeeb nkab steel | ||

| 123 | Txiav xeem | Tau txais cov yeeb nkab lub cev hauv qab cov roj txiav cov khoom siv los xyuas kom meej tias tsis muaj kev txiav lossis kev puas tsuaj | ||

| 124 | Nws tsis yog qhov tsim nyog rau pickling galvanized sundries | Kev soj ntsuam pom kom paub tseeb tias tsis muaj roj stains, xim thiab lwm yam tsis yooj yim rau pickle cov khib nyiab, tiv thaiv kom tsis txhob plating. | ||

| Pickling steel yeeb nkab | Tshem cov sundries xws li oxide nplai tsim nyob rau saum npoo ntawm cov yeeb nkab steel | 125 | Qhov concentration ntawm acid | Cov ntsiab lus ntawm hydrogen chloride hauv acid concentration yuav tsum tau tswj ntawm 20% -24% |

| 126 | Underpickling tshuaj xyuas ntawm cov yeeb nkab steel | Txhawm rau tiv thaiv (1) lub sijhawm pickling tsis txaus, tsis tshua muaj kua qaub, tsis tshua muaj siab (kub yuav tsum tau tswj hauv 25-40 ℃, acid concentration ntawm hydrogen chloride yog 20% -24%) (2) tsawg dua lub sij hawm ntawm lub raj ntim (3) lub neej ntawm silicate nyob rau hauv lub cub tawg welded steel raj | ||

| ntim khoom | Packed raws li tus naj npawb ntawm cov yeeb nkab steel ib thooj | 127 | Packing siv tshuaj xyuas | packing steel yeeb nkab yog hexagonal, 6 packing siv, tag nrho cov nqa tawm nyob rau hauv peb lub Hoobkas, ob qho tag nrho ntawm cov packing siv los ntawm qhov kawg ntawm qhov yuam kev ntawm ± 10mm, nruab nrab 4 yuav tsum sib npaug zos, packing siv vuam yuav tsum tau raws li txoj cai, ca, packing siv tsis pub deflection junction yuav tsum tau raws li 4 ° packing belt. kev xav tau |

| 128 | Kev kos npe | Cov ntsiab lus yog qhov tseeb, lub dav hlau nce siab, cov khoom lag luam tiav cov yeeb nkab yuav tsum tau muab tso rau ntawm txhua cov yeeb nkab baffle kom haum rau sab xis ntawm thawj vuam packing siv nyob rau hauv nruab nrab, thiab lub hauv paus Ted embellish sau yog meej thiab tsis askew. |