TS EN 10219 Komposisi kimia, sifat mekanik, toleransi lan standar tes kanggo pipa baja jahitan lurus

N10219-2006 Pipa baja berongga las kadhemen saka baja non-paduan lan baja struktur butir halus (LSAW longitudinal submerged arc welded steel pipe)

Bahan utama S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH, S420MH, S420MLH, S460MLH, S460MLH, S460MH, S460MH, S460MH

1. Tegese angka lan aksara ing EN10219-2006

S: Struktur baja

Nomer sawise S: zui kekuatan ngasilaken cilik (kekandelan tembok ≤ 16mm)

JR: test impact ing suhu normal ≥ 27J

J0: 0 ℃ impact test ≥ 27J

J2: - 20 ℃ impact test ≥ 27J

K2: - 20 ℃ impact test ≥ 40J

N: Rolling normal utawa normal (baja gandum alus, test impact kudu dilakoni, suhu zui luwih murah tinimbang - 20 ℃ ≥ 40J)

M: Rolling kontrol termo-mekanis (tes impact kudu dilakoni, lan suhu zui luwih murah tinimbang - 20 ℃ ≥ 40J)

50: - 50 ℃ impact test ≥ 27J

H: profil kothong

2. Komposisi kimia (ketebalan T ≤ 40mm) lan sifat mekanik

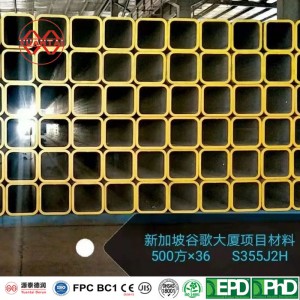

Yuantai Derun bisa ngasilake pipa baja EN10219-2006. Apa bahan saka S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH, S460NH lan S460NL2H ing EN2102H

Bahan apa S235JRH, materi apa sing digunakake, perusahaan sing bisa ngasilake pipa baja jahitan lurus S235JRH

Komposisi kimia saka S235JRH

Karbon ≤ 0,17%, silikon ≤ ora dibutuhake, mangan ≤ 1,40%, fosfor ≤ 0,04%, belerang ≤ 0,04%, nitrogen ≤ 0,009%

S235JRH sifat mekanik

3 mm

16 mm

Apa materi S275J0H, lan materi apa sing kudu diganti, perusahaan sing bisa ngasilake pipa baja jahitan lurus S275J0H

Komposisi kimia saka S275J0H

Karbon ≤ 0,20%, silikon ≤ ora dibutuhake, mangan ≤ 1,50%, fosfor ≤ 0,035%, belerang ≤ 0,035%, nitrogen ≤ 0,009%

S275J0H sifat mekanik

3 mm

16 mm

Bahan apa S275J2H, materi apa sing digunakake, perusahaan sing bisa ngasilake pipa baja jahitan lurus S275J2H

Komposisi kimia saka S275J2H

Karbon ≤ 0,20%, silikon ≤ ora dibutuhake, mangan ≤ 1,50%, fosfor ≤ 0,030%, belerang ≤ 0,030%, nitrogen ≤ ora dibutuhake

S275J2H sifat mekanik

3 mm

16 mm

Apa materi S355J0H lan materi apa sing digunakake kanggo ngganti? Perusahaan sing bisa ngasilake pipa baja jahitan lurus S355J0H

S355J0H Komposisi kimia

Karbon ≤ 0,22%, silikon ≤ 0,55%, mangan ≤ 1,60%, fosfor ≤ 0,035%, belerang ≤ 0,035%, nitrogen ≤ 0,009%

S355J0H sifat mekanik

3 mm

16 mm

Bahan apa S355J2H, materi apa sing digunakake, perusahaan sing bisa ngasilake pipa baja jahitan lurus S355J2H

Komposisi kimia S355J2H

Karbon ≤ 0,22%, silikon ≤ 0,55%, mangan ≤ 1,60%, fosfor ≤ 0,030%, belerang ≤ 0,030%, nitrogen ≤ ora dibutuhake

S355J2H sifat mekanik

3 mm

16 mm

Apa materi S355K2H, materi apa sing digunakake, lan perusahaan sing bisa ngasilake pipa baja jahitan lurus S355K2H

Komposisi kimia S355K2H

Karbon ≤ 0,22%, silikon ≤ 0,55%, mangan ≤ 1,60%, fosfor ≤ 0,030%, belerang ≤ 0,030%, nitrogen ≤ ora dibutuhake

S355K2H sifat mekanik

3 mm

16 mm

Apa materi S275NH? Bahan apa sing digunakake tinimbang? Perusahaan sing bisa ngasilake pipa baja jahitan lurus S275NH

Komposisi kimia S275NH

Karbon ≤ 0,20%, silikon ≤ 0,40%, mangan ≤ 0,5-1,40%, fosfor ≤ 0,035%, belerang ≤ 0,030%, niobium ≤ 0,05%, vanadium ≤ 0,05%

Aluminium ≥ 0,020%, titanium ≤ 0,03%, kromium ≤ 0,30%, nikel ≤ 0,30%, molibdenum ≤ 0,10%, tembaga ≤ 0,35%, nitrogen ≤ 0,015%

Sifat mekanik S275NH

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 275MPa, kekuatan tarik ≥ 370-510MPa, elongasi ≥ 24%

16 mm

Bahan apa S275NLH, materi apa sing digunakake, perusahaan sing bisa ngasilake pipa baja jahitan lurus S275NLH

Komposisi kimia S275NLH

Karbon ≤ 0,20%, silikon ≤ 0,40%, mangan ≤ 0,5-1,40%, fosfor ≤ 0,030%, belerang ≤ 0,025%, niobium ≤ 0,05%, vanadium ≤ 0,05%

Aluminium ≥ 0,020%, titanium ≤ 0,03%, kromium ≤ 0,30%, nikel ≤ 0,3%, molibdenum ≤ 0,10%, tembaga ≤ 0,35%, nitrogen ≤ 0,015%

S275NLH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 275MPa, kekuatan tarik ≥ 370-510MPa, elongasi ≥ 24%

16 mm

Apa materi S355NH? Bahan apa sing digunakake tinimbang? Perusahaan sing bisa ngasilake pipa baja jahitan lurus S355NH

Komposisi kimia S355NH

Karbon ≤ 0,20%, silikon ≤ 0,50%, mangan ≤ 0,9-1,65%, fosfor ≤ 0,035%, belerang ≤ 0,030%, niobium ≤ 0,05%, vanadium ≤ 0,1%

Aluminium ≥ 0,020%, titanium ≤ 0,03%, kromium ≤ 0,30%, nikel ≤ 0,5%, molibdenum ≤ 0,10%, tembaga ≤ 0,35%, nitrogen ≤ 0,015%

Sifat mekanik S355NH

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 355MPa, kekuatan tarik ≥ 470-630MPa, elongasi ≥ 22%

16 mm

Bahan apa S355NLH, materi apa sing digunakake kanggo ngganti, lan perusahaan endi sing bisa ngasilake pipa baja jahitan lurus S355NLH

Komposisi kimia S355NLH

Karbon ≤ 0,18%, silikon ≤ 0,50%, mangan ≤ 0,9-1,65%, fosfor ≤ 0,030%, belerang ≤ 0,025%, niobium ≤ 0,05%, vanadium ≤ 0,1%

Aluminium ≥ 0,020%, titanium ≤ 0,03%, kromium ≤ 0,30%, nikel ≤ 0,5%, molibdenum ≤ 0,10%, tembaga ≤ 0,35%, nitrogen ≤ 0,015%

S355NLH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 355MPa, kekuatan tarik ≥ 470-630MPa, elongasi ≥ 22%

16 mm

Bahan apa S460NH, materi apa sing digunakake, lan perusahaan endi sing bisa ngasilake pipa baja jahitan lurus S460NH

Komposisi kimia S460NH

Karbon ≤ 0,20%, silikon ≤ 0,60%, mangan ≤ 1,0-1,70%, fosfor ≤ 0,035%, belerang ≤ 0,030%, niobium ≤ 0,05%, vanadium ≤ 0,2%

Aluminium ≥ 0,020%, titanium ≤ 0,03%, kromium ≤ 0,30%, nikel ≤ 0,8%, molibdenum ≤ 0,10%, tembaga ≤ 0,35%, nitrogen ≤ 0,025%

Sifat mekanik S460NH

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 460MPa, kekuatan tarik ≥ 550-720MPa, elongasi ≥ 17%

16 mm

Bahan apa S460NLH, bahan apa sing digunakake kanggo ngganti, lan perusahaan endi sing bisa ngasilake pipa baja jahitan lurus S460NLH

Komposisi kimia S460NLH

Karbon ≤ 0,20%, silikon ≤ 0,60%, mangan ≤ 1,0-1,70%, fosfor ≤ 0,030%, belerang ≤ 0,025%, niobium ≤ 0,05%, vanadium ≤ 0,2%

Aluminium ≥ 0,020%, titanium ≤ 0,03%, kromium ≤ 0,30%, nikel ≤ 0,8%, molibdenum ≤ 0,10%, tembaga ≤ 0,35%, nitrogen ≤ 0,025%

S460NLH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 460MPa, kekuatan tarik ≥ 550-720MPa, elongasi ≥ 17%

16 mm

Apa materi S275MH? Bahan apa sing digunakake tinimbang? Perusahaan sing bisa ngasilake pipa baja jahitan lurus S275MH

Komposisi kimia S275MH

Karbon ≤ 0,13%, silikon ≤ 0,50%, mangan ≤ 1,50%, fosfor ≤ 0,035%, belerang ≤ 0,030%, niobium ≤ 0,05%, vanadium ≤ 0,08%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,30%, molibdenum ≤ 0,20%, nitrogen ≤ 0,02%,

S275MH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 275MPa, kekuatan tarik ≥ 360-510MPa, elongasi ≥ 24%

16 mm

Bahan apa S275MLH, materi apa sing digunakake, lan perusahaan endi sing bisa ngasilake pipa baja jahitan lurus S275MLH

Komposisi kimia S275MLH

Karbon ≤ 0,13%, silikon ≤ 0,50%, mangan ≤ 1,50%, fosfor ≤ 0,030%, belerang ≤ 0,025%, niobium ≤ 0,05%, vanadium ≤ 0,08%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,30%, molibdenum ≤ 0,20%, nitrogen ≤ 0,02%,

Sifat mekanik S275MLH

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 275MPa, kekuatan tarik ≥ 360-510MPa, elongasi ≥ 24%

16 mm

Apa materi S355MH? Bahan apa sing digunakake tinimbang? Perusahaan sing bisa ngasilake pipa baja jahitan lurus S355MH

Komposisi kimia S355MH

Karbon ≤ 0,14%, silikon ≤ 0,50%, mangan ≤ 1,50%, fosfor ≤ 0,035%, belerang ≤ 0,030%, niobium ≤ 0,05%, vanadium ≤ 0,10%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,3%, molibdenum ≤ 0,20%, nitrogen ≤ 0,02%,

S355MH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 355MPa, kekuatan tarik ≥ 450-610MPa, elongasi ≥ 22%

16 mm

Apa materi S355MLH, materi apa sing digunakake, perusahaan sing bisa ngasilake pipa baja jahitan lurus S355MLH

Komposisi kimia S355MLH

Karbon ≤ 0,14%, silikon ≤ 0,50%, mangan ≤ 1,50%, fosfor ≤ 0,030%, belerang ≤ 0,025%, niobium ≤ 0,05%, vanadium ≤ 0,10%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,3%, molibdenum ≤ 0,20%, nitrogen ≤ 0,02%,

S355MLH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 355MPa, kekuatan tarik ≥ 450-610MPa, elongasi ≥ 22%

16 mm

Bahan apa S420MH, materi apa sing digunakake, perusahaan sing bisa ngasilake pipa baja jahitan lurus S420MH

Komposisi kimia S420MH

Karbon ≤ 0,16%, silikon ≤ 0,50%, mangan ≤ 1,70%, fosfor ≤ 0,035%, belerang ≤ 0,030%, niobium ≤ 0,05%, vanadium ≤ 0,12%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,3%, molibdenum ≤ 0,20%, nitrogen ≤ 0,02%,

Sifat mekanik S420MH

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 420MPa, kekuatan tarik ≥ 500-660MPa, elongasi ≥ 19%

16 mm

Apa materi S420MLH, materi apa sing digunakake, perusahaan sing bisa ngasilake pipa baja jahitan lurus S420MLH

Komposisi kimia S420MLH

Karbon ≤ 0,16%, silikon ≤ 0,50%, mangan ≤ 1,70%, fosfor ≤ 0,030%, belerang ≤ 0,025%, niobium ≤ 0,05%, vanadium ≤ 0,12%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,3%, molibdenum ≤ 0,20%, nitrogen ≤ 0,02%,

S420MLH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 420MPa, kekuatan tarik ≥ 500-660MPa, elongasi ≥ 19%

16 mm

Apa materi S460MH? Bahan apa sing digunakake tinimbang? Perusahaan sing bisa ngasilake pipa baja jahitan lurus S460MH

Komposisi kimia S460MH

Karbon ≤ 0,16%, silikon ≤ 0,60%, mangan ≤ 1,70%, fosfor ≤ 0,035%, belerang ≤ 0,030%, niobium ≤ 0,05%, vanadium ≤ 0,12%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,3%, molibdenum ≤ 0,20%, nitrogen ≤ 0,025%,

S460MH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 460MPa, kekuatan tarik ≥ 530-720MPa, elongasi ≥ 17%

16 mm

Bahan apa S460MLH, materi apa sing digunakake, lan perusahaan endi sing bisa ngasilake pipa baja jahitan lurus S460MLH

Komposisi kimia S460MLH

Karbon ≤ 0,16%, silikon ≤ 0,60%, mangan ≤ 1,70%, fosfor ≤ 0,030%, belerang ≤ 0,025%, niobium ≤ 0,05%, vanadium ≤ 0,12%,

Aluminium ≥ 0,020%, titanium ≤ 0,05%, nikel ≤ 0,3%, molibdenum ≤ 0,20%, nitrogen ≤ 0,025%,

S460MLH sifat mekanik

Ketebalan tembok ≤ 16mm: kekuatan ngasilake ≥ 460MPa, kekuatan tarik ≥ 530-720MPa, elongasi ≥ 17%

16 mm

3. EN10219-2006 Rentang toleransi umum

Panyimpangan diameter lan bunder (kanggo pipa baja SAWL LSAW):

Toleransi diameter njaba ≤± 1%, zui cilik ± 0.5mm, zui gedhe ± 10mm

Cara pangukuran diameter njaba yaiku metode keliling, lan diameter njaba sing diukur = keliling / keliling.

Ovality: 2% nalika diameter / kekandelan njaba ≤ 100

Cara pitungan toleransi=(zui gedhe diameteripun njaba - zui cilik diameteripun njaba)/standar njaba diameteripun X100%

Penyimpangan ketebalan tembok (kanggo SAWL longitudinal submerged arc welded pipe baja):

Dhiameter njaba ≥ 406mm, toleransi kekandelan tembok ≤± 10%, zui luwih gedhe ± 2mm

Penyimpangan kelurusan (kanggo SAWL longitudinal submerged arc welded steel pipe, L yaiku dawa pipa baja ing mm):

Penyimpangan straightness full-dawa ≤ 0,002L

Panyimpangan massa: ± 6% (saben unit dawa)

Toleransi dhuwur saka welds internal lan eksternal saka pipa busur submerged

Kekandelan (T) ≤ 14.2zui Gedhe las dhuwur 3.5mm

Kekandelan (T) > 14.2zui Dhuwur las gedhe 4.8mm

Toleransi dawa:

Sembarang dawa: 4000-16000mm, single floating range 2000mm, 10% saka produk sing diwenehake bisa luwih murah tinimbang nilai cilik zui sing ditemtokake ing urutan kasebut, nanging ora luwih murah tinimbang 75% saka nilai cilik zui

Kira-kira dawa: kisaran toleransi yaiku 0 nganti + 50mm nalika ≥ 4000mm

dawa:

Kisaran toleransi yaiku 0 nganti 5mm nalika dawane kurang saka 6000 mm

Kisaran toleransi 0 nganti 15mm nalika 6000mm ≤ dawa ≤ 10000mm

Toleransi 0 kanggo 5mm + 1mm / m nalika dawa> 10000mm

4. Tes NDT:

Tes Radiografi lan Ultrasonik (RT&UT)

Radiografi (RT): 100% inspeksi pipa baja

Ultrasonik (UT): 100% inspeksi pipa baja

Tekanan banyu kudu sesuai karo standar utawa dirundingake dening loro pihak

A sawetara tembung saka Yuantai Derun Steel Group

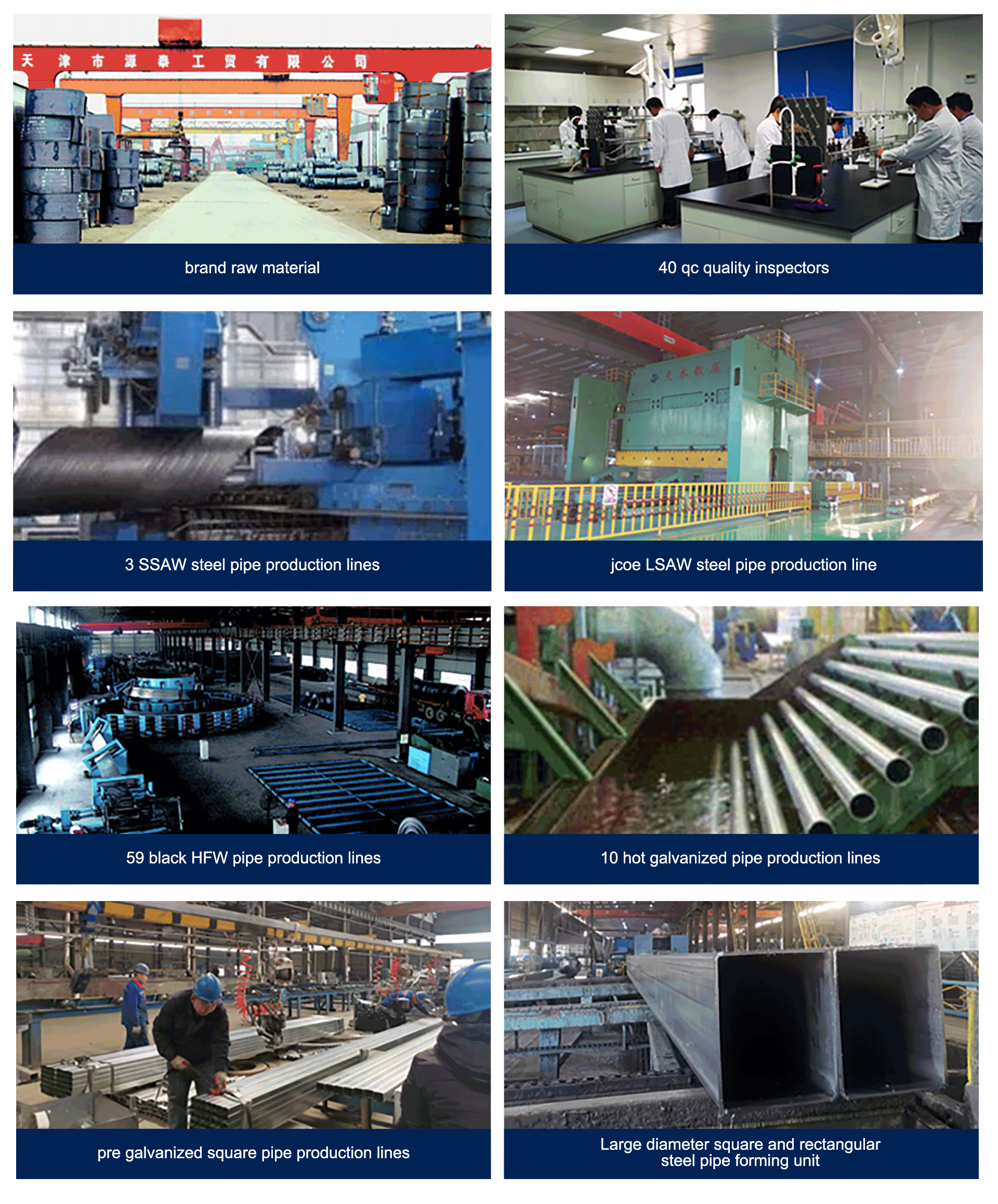

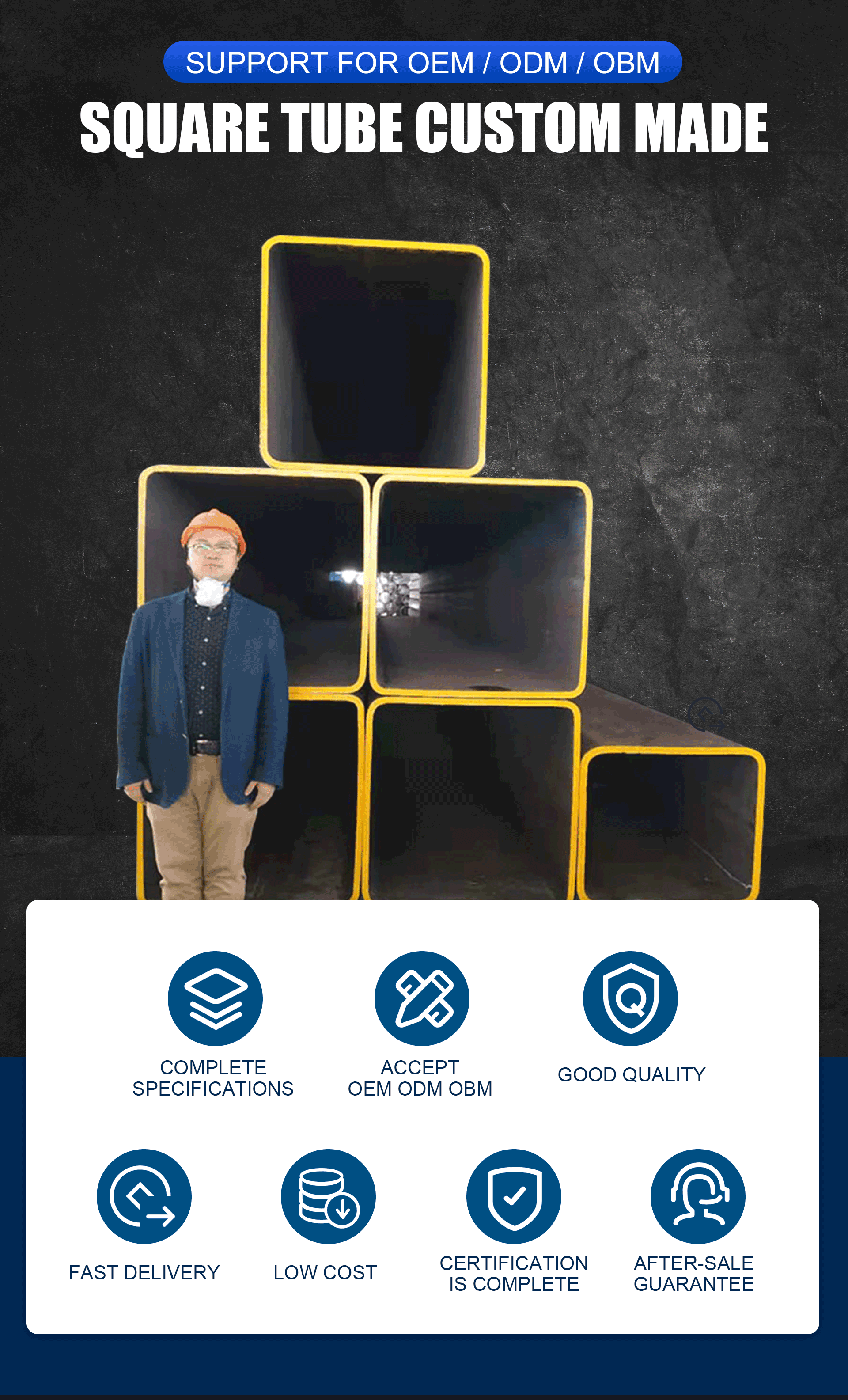

Kanthi output taunan 10 yuta ton, Yuantai Derun minangka produsen paling gedhe saka pipa persegi ERW, pipa persegi panjang, pipa berongga, pipa galvanis, pipa baja las busur sing dilas lan pipa las spiral ing China. Penjualan taunan tekan 15 milyar dolar AS. Yuantai Derun duweni 59 irengPipa ERW Kabjalur produksi, 10pipa galvanisjalur produksi lan 3 jalur produksi pipa las spiral. Pipa kothak 10 * 10 * 0.5mm nganti 1000 * 1000 * 60MM,pipa baja persegi panjang10 * 15 * 0.5mm to 800 * 1100 * 60MM, straight seam welded steel pipe φ 355.6-2000mm, spiral pipe Φ 219-2032mm, seamless pipe φ 21.3-820mm。 Yuantai Derun can produce square rectangular pipes conforming to ASTM A500, JIS g3466, en10219, din2240 and as1163. Yuantai Derun has the largest square tube inventory in China, which can meet the direct purchase needs of customers. Welcome to contact Yuantai Derun, e-mail: sales@ytdrgg.com , real-time connection factory inspection or factory visit!

Spesifikasi bagean kothong persegi lan persegi dowo

| OD(MM) | Ketebalan (MM) | OD(MM) | Ketebalan (MM) | OD(MM) | Ketebalan (MM) | OD(MM) | Ketebalan (MM) |

| 20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

| 1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

| 1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

| 1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

| 1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

| 2.0 | 2.5-4.0 | 11.5-11.75 | |||||

| 20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | ||||

| 1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | |||

| 1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

| 1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

| 1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

| 2.2 | 2.20 | 13.5-13.75 | |||||

| 2.5-3.0 | 2.5-2.75 | 15.5-30 | |||||

| 20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | ||

| 1.4 | 5.5-6.3 | 4.5-4.75 | |||||

| 1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

| 2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

| 2.2 | 2.75 | 13.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | |||

| 3.25-4.0 | 5.5-6.3 | 4.5-4.75 | |||||

| 25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

| 1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

| 1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

| 1.8 | 3.0-3.75 | 12-13.75 | |||||

| 2.0 | 4.5-4.75 | 15.5-30 | |||||

| 2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | |||

| 2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

| 4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

| 5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

| 5.75-6.3 | 3.0-4.75 | 15.5-30 | |||||

| 40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 750*750 | ||

| 1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

| 2.2 | 2.75 | 15.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | |||

| 3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

| 4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

| 1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | ||||

| 1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | |||

| 1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

| 2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | ||||

| 3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | |||

| 4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

| 1.5 | 12.25 | 15.5-40 | |||||

| 1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 400*400 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | ||

| 1.8 | 4.5-6.3 | 9.5-9.75 | |||||

| 2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

| 2.2 | 9.5-9.75 | 12-13.75 | |||||

| 2.5-3.0 | 11.5-25 | 15.5-40 | |||||

| 3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1100*1100 | ||

| 4.25-4.75 | 3.5-3.75 | 11.5-11.75 | 20-60 | ||||

| 5.0-5.75 | 4.25-7.75 | 12-13.75 | |||||

| 7.5-8 | 9.5-25 | 15.5-40 |

01 DERECT DEAL

Kita wis khusus ing

produksi baja kanggo akèh taun

- 02 LENGKAP

- SPESIFIKASI

OD: 10*10-1000*1000MM 10*15-800*1100MM

Ketebalan: 0.5-60mm

Dawane: 1-24M

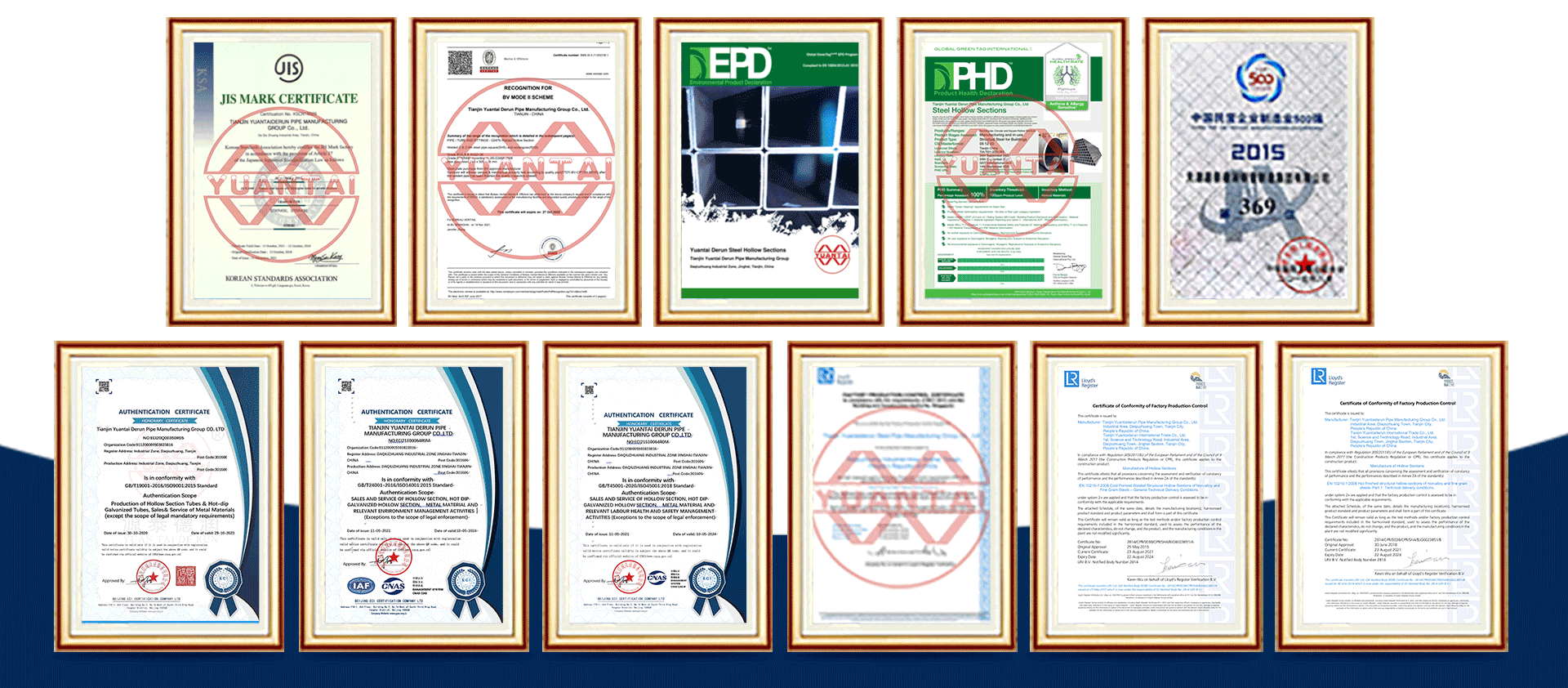

3 SERTIFIKASI IS

LENGKAP

bisa ngasilake produk pipa baja donya

stardard, kayata standar Eropa, standar Amerika,

Standar Jepang, standar Astralian, standar asli

lan liya-liyane.

04 INVENTORI Ageng

Spesifikasi umum persediaan perennial saka

200000 ton

A: Kita pabrik.

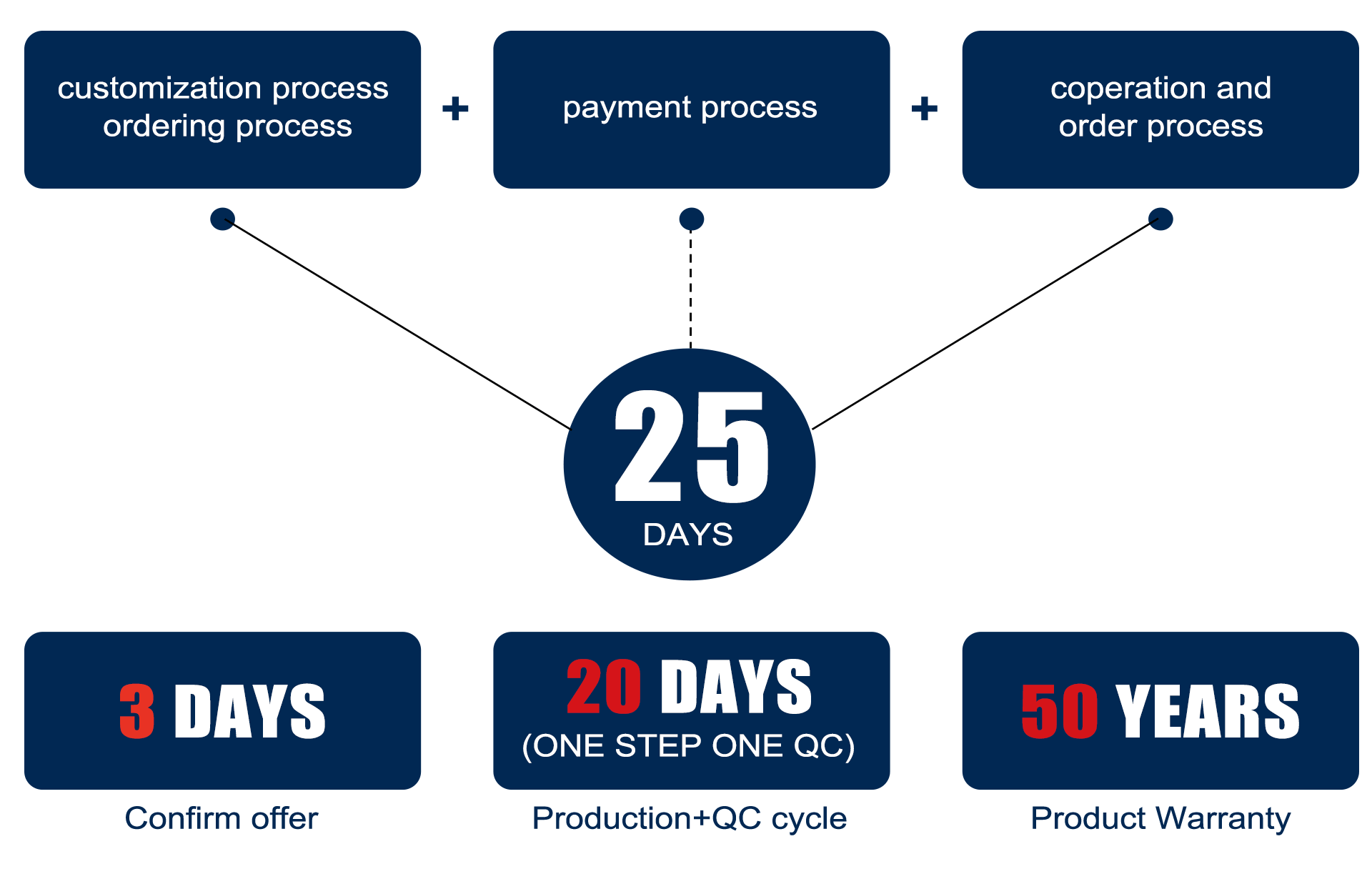

A: Umumé iku 5-10 dina yen barang ing Simpenan. utawa iku 30 dina yen barang ora ing Simpenan, iku miturut jumlahe.

A: Ya, kita bisa menehi sampel kanthi gratis kanthi biaya pengiriman sing dibayar dening pelanggan.

A: Pembayaran <= 1000USD, 100% ing advance. Pembayaran> = 1000USD 30% T / T ing advance, imbangan sadurunge shippment.Yen sampeyan duwe pitakonan liyane, pls aran gratis kanggo hubungi kita ing ngisor iki

Perusahaan attaches gedhe wigati kanggo kualitas produk, invests akeh banget ing introduksi saka peralatan majeng lan profesional, lan dadi kabeh metu kanggo nyukupi kabutuhan pelanggan ing ngarep lan luar negeri.

Isi bisa kira-kira dipérang dadi: komposisi kimia, kekuatan ngasilaken, kekuatan tensile, impact property, etc

Ing wektu sing padha, perusahaan uga bisa nindakake deteksi cacat on-line lan annealing lan pangolahan perawatan panas liyane miturut kabutuhan customer.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.yaiku pabrik pipa baja sing disertifikasi deningEN/ASTM/ JISspesialisasine ing produksi lan ekspor kabeh jinis pipa persegi dowo kothak, pipe galvanis, pipe gandheng ERW, pipe spiral, submerged busur gandheng pipe, pipe lapisan sakcara, pipe rapi, werna ditutupi kumparan baja, galvanis kumparan baja lan products.With baja liyane transportasi trep, iku 190 kilometer adoh saka Beijing Capital Xang International Airport lan 800 kilometer saka Tianjin.

Whatsapp: +8613682051821

Kirim pesen kanggo kita:

-

tabung persegi mekanik

-

Disesuaikan spesifikasi lengkap tabung baja persegi panjang

-

2″X 2″X .250″ Wall Steel Square Tube 12″ Potongan

-

Diameter gedhe 48 Inch Spiral Welded Steel Pipe / Electric Pipe Penstock

-

1-3/4″ x 1-3/4″ x .065 Tabung persegi dekoratif galvanis

-

Rega kompetitif ms astm a53 tabung baja persegi galvanis