Secundum normam API SPEC 5CT1988 editionem primam Instituti Petrolei Americani, genus chalybis tubi olei API 5CT in decem genera dividi potest, inter quae H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 et Q-125. Tubos olei et tubas olei API 5CT K55 cum filo et copula praebemus, vel productum nostrum secundum formas sequentes ad optionem offerimus.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Specificationes Tuborum Involucri API 5CT K55

| SPECIFICATIONES TUBORUM INTEGUMENTORUM API 5CT K55 | ||

| Magnitudines Disponibiles | Diametros externi 2 3/8″, 2 7/8″ et 3 ½″ | |

| Gradus | J55, J55-FBNAU, N80, L80, P110 | |

| Tubus | 1 1/4 “ – 2 1/16” Nom. | |

| Normae | API SPEC 5CT | |

| Exemplar in Usu Communi | 2-3/8″, 2-7/8″, 3-1/2″, 4″, 4-1/2″ | |

| Ambitus Longitudinis | R1(6.10-7.32m), R2(8.53-9.75m), R3 (11.58-12.8m) | |

| Gradus Chalybis (Genera Involucri, Genera Tuborum) | J55, K55, N80-1, N80-Q, L80, P110 | |

| Genus Fili Cochleae | Extremum filum non perturbatum (NUE), extremum filum perturbatum externum (EUE) | |

| Specialitates |

| |

| Finis Perficiendi | Extremitates Externae Perturbationis (EUE), Articulatio Aequa, PH6 (et nexus aequivalentes), Articulatio Integralis (IJ) | |

API 5CT K55 Tuborum Involucri Tensile et Duritiae Requisita

| Grex | Gradus | Typus | Elongatio totalis sub onere % | Robur cessionis MPa | Robur tensile minimum MPa | Duritia ad maximum. | Crassitudo parietis specificata mm | Variatio duritiae permissa b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | maximus | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | DCLV | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | DCLXXXIX | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | DCLXXXIX | - | - | - | - | |

| R95 | - | 0.5 | DCLV | 758 | DCCXXIV | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | DCLV | DCLV | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | DCLV | DCLV | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | DCLV | DCLV | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | DCXXI | DCCXXIV | DCLXXXIX | 25.4 | 255 | ≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | DCLV | 758 | DCCXXIV | 25.4 | 255 | ≤ 12.70 12.71 to 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | DCCCXXVIII | DCCXCIII | 30 | 286 | ≤ 12.70 12.71 ad 19.04 19.05 ad 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | DCCCLXII | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | DCCCLXII | 1034 | 931 | b | - | ≤ 12.70 12.71 ad 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aIn casu controversiae, methodus referentialis adhibenda est probatio duritiae Rockwell C laboratorio facta. bNulli limites duritiae specificantur, sed maxima variatio secundum 7.8 et 7.9 API Spec. 5CT restringitur. | ||||||||||

Dimensiones Tuborum Involucri K55

| Magnitudines Tuborum Tubarium, Magnitudines Tuborum Petrolei et Magnitudines Tuborum Drift | |

|---|---|

| Diameter Externus (Magnitudines Tuborum Involucri) | 4 1/2″-20″, (114.3–508 mm) |

| Magnitudines Involucri Standardis | 4 1/2″-20″, (114.3–508 mm) |

| Typus Fili | Involucrum filum fulcri, involucrum filum rotundum longum, involucrum filum rotundum breve |

| Functio | Tubum protegere potest. |

Tubus Olei pro Industriis Petrolei et Gasis Naturalis

| Nomen Tuborum | Specificatio | Gradus Chalybis | Norma | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Tubus Tubi Petrolei | 127-508 | 5.21-16.66 | VI-XII | J55M55.K55. L80. N80P110. | Specificatio API 5CT (8) |

| Tubi Petrolei | 26.7-114.3 | 2.87-16.00 | VI-XII | J55. M55. K55. L80. N80. P110. | Specificatio API 5CT (8) |

| Copulatio | 127-533.4 | 12.5-15 | VI-XII | J55. M55. K55. L80. N80. P110. | Specificatio API 5CT (8) |

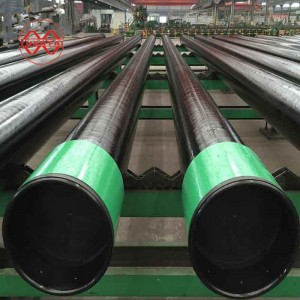

Proprietates Tuborum Involucri API 5CT K55

- Tubi involucri API 5CT K55 cum longitudine libera ab 8m ad 13m secundum normam SY/T6194-96 offeruntur. Attamen etiam longitudine non minore quam 6m praesto sunt, et eius quantitate non plus quam 20% esse debet.

- Deformationes supra memoratae in superficie exteriori copulae tuborum involucri API 5CT K55 apparere non permittuntur.

- Quaevis deformatio, qualis est capillatura, separatio, plica, fissura vel crusta, non est acceptabilis in superficiebus tam internis quam externis producti. Haec omnia vitia omnino removenda sunt et profunditas remota non excedere debet 12.5% crassitudinis parietis nominalis.

- Superficies fili copulae et tubi involucri API 5CT K55 laevigata esse debet, sine ullis laminis, scissuris, aut aliis vitiis quae negative afficere possint firmitatem et coniunctionem artam.

Operatoribus olei et gasi magni momenti est ut involucra puteorum productionis a corrosione protectione cathodica protegant, et tubi API 5CT OilField imprimis ad translationem olei et gasorum serviunt.

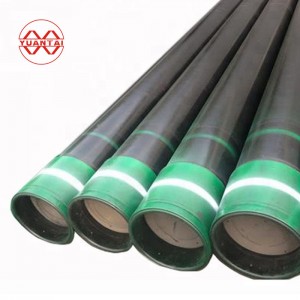

API 5CT Gradus K55 Tuborum Involucri Chalybis Color Code

| Nomen | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Involucrum | fascia viridis clara | duae fasciae virides clarae | fascia rubra clara | fascia rubra clara + fascia viridis | fascia rubra + fascia fusca | fascia alba clara |

| Copulatio | copulatio viridis integra + fascia alba | copulatio viridis tota | tota rubra copulatio | tota rubra copula + fascia viridis | tota copulatio rubra + fascia fusca | tota alba copulatio |

Specificationes tubi involucri ISO/API / API 5CT K55

| Codea | Diametros Exteriores | Pondus nominale (cum filo et copulatio) b,c | Crassitudo muri | Genus processus finis | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Librae/pedes | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | XXIII.VII | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| VI-V-VIII | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| VI-V-VIII | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| VI-V-VIII | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| VI-V-VIII | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| VII-V-VIII | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| VII-V-VIII | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| VII-V-VIII | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| VII-V-VIII | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| VII-V-VIII | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| VII-V-VIII | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| VII-V-VIII | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| VII-V-VIII | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| VIII-V-VIII | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| VIII-V-VIII | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| VIII-V-VIII | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| VIII-V-VIII | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| VIII-V-VIII | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| VIII-V-VIII | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| VIII-V-VIII | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Tubus involucri API 5CT Codea | Diametros exterior tubi involucri API 5CT | Tubus involucri API 5CT Pondus nominale (cum filo) et copulatio) b,c | Crassitudo parietis tubi involucri API 5CT | Typus processus finis tubi involucri API 5CT | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Librae/pedes | K55 | C95 | 1, Q. | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| XI-III-IV | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| XI-III-IV | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| XI-III-IV | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| XI-III-IV | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| XIII-III-VIII | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| XIII-III-VIII | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| XIII-III-VIII | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| XIII-III-VIII | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| XIII-III-VIII | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| XVIII-V-VIII | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Filum rotundum breve, L-Filum rotundum longum, B-Filum contrafulcimenti | ||||||||||||

| a. Codex ad ordinationem referentiae adhibetur. | ||||||||||||

| b. Pondus nominale involucri filetati et coniuncti (columna 2) ad referentiam tantum monstratur. | ||||||||||||

| c. Chalybs chromatus martensiticus (L80 9Cr et 13Cr) a chalybe carbonico densitate differt. Pondus chalybis chromati martensitici monstratum non est valor exactus. Factor correctionis massae 0.989 adhiberi potest. | ||||||||||||

| d. Involucra chalybis qualitatis C90, T95 et Q125 secundum specificationem, pondus et crassitudinem parietis in tabula vel ordine supra scriptas suppeditanda sunt. | ||||||||||||

Compositio Chemica API 5CT K55

| Grex | Gradus | Typus | C | Mn | Mo | Cr | Ni max. | Cu max. | P maximus. | S maximus. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | maximum | min. | maximum | min. | maximum | min. | maximum | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45°C | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 miliarda | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Contentum carbonis pro L80 usque ad 0.50% maximum augeri potest si productum oleo extinctum est. b Contentum molybdeni pro Gradu C90 Typo 1 nullam tolerantiam minimam habet si crassitudo parietis minor quam 17.78 mm est. c Contentum carbonis pro R95 usque ad 0.55% maximum augeri potest si productum oleo extinguatur. d Contentum molybdeni pro T95 Typo 1 ad minimum 0.15% reduci potest si crassitudo parietis minor quam 17.78 mm est. e Pro EW Grade P110, contentum phosphori erit maximum 0.020% et contentum sulphuris maximum 0.010%. NL = nullus limes. Elementa demonstrata in analysi producti referri debent. | |||||||||||||||

Proprietates Mechanicae API 5CT k55 Gr.

| API 5CT Involucri Norma | Typus | Robur Tensile Involucri API 5CT MPa | Robur Cedendi Involucri API 5CT MPa | Duritia Involucri API 5CT Maximus |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | —- |

| K55 | ≥517 | ≥655 | — | |

| N80 | ≥689 | 552 ~ 758 | — | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | —- |

Yuantai Derun, cum productione annua quinque milionum tonnarum, est maxima fabricatrix tuborum quadratorum ERW, tuborum rectangularium, tuborum cavorum, tuborum galvanizatorum et tuborum spiraliter consutorum in Sinis. Venditiones annuae ad quindecim miliarda dollariorum pervenerunt. Yuantai Derun habet quinquaginta novem lineas productionis tuborum nigrorum ERW, decem lineas productionis tuborum galvanizatorum et tres lineas productionis tuborum spiraliter consutorum. Tubi quadrati 20 * 20 * 1mm ad 500 * 500 * 40MM, tubi rectangulares chalybei 20 * 30 * 1.2mm ad 400 * 600 * 40MM, tubi spirales Ø 219-1420mm ex gradibus chalybis a Q(s) 195 ad Q(s) 345B / gr.a-gr.d fieri possunt. Yuantai Derun tubos quadratos rectangulares secundum ASTM A500, JIS g3466, en10219, din2240 et as1163 producere potest. Yuantai Derun maximum copiam tuborum quadratorum rectangularium in Sinis habet, quae postulationi emptionis directae clientium satisfacere potest.

Omnes ad Yuantai Derun contactum salutant. Inscriptio electronica:sales@ytdrgg.com, et inspectionem connexionis in tempore reali ad officinam vel officinam visitandam!

| Productum | Api 5L X42/X52/X60/X70 |

| Norma | Api 5L |

| Gradus | X42, X52, X60, X65, X70 |

| Ars | Frigido laminatum |

| Diametros exterior mm | 21.3mm 2032mm |

| Pondus mm | 0.5mm-60mm |

| Longitudo | 5.8m/6m/11.8m/12m vel prout requiritur |

| Superficies | Pictura Nigra/Galvanizata/Vernis/Indumentum 3LPE/Nudum |

| Locus originis | Sina (Continens) |

| Applicatio | 1. Tubus Fluidi |

| 2. Tubus Olei | |

| 3. Tubus Gasis | |

| 4. Tubi Caldarii | |

| 5. Tubus Structurae | |

| 6. Tubus stercoris etc. | |

| Sarcinatio | Tubi infra octo unciarum in fasciculo erunt. Supra autem in massa. |

| Conditiones Commerciales | FOB, CFR, CIF, CIP etc. |

| Terminus Solutionis | 1.30% TT anticipatum et reliquum post inspectionem solutum |

| 2.LC ad conspectum | |

| Tempus Traditionis | 7-30 dies operabiles post acceptum praesolutionem vel LC |

EXHIBITIO OPERARII FABRICAE

Mulieres viris non inferiores sunt.

Perseverantia constans unum campionem categoriae consecuta est.

Tempus omnia mutare potest, sed tempus non omnia mutare potest, exempli gratia, cor initiale.

Populus Yuantai in variis locis pugnat

EXHIBITIONEM OFFICINAE FABRICAE

PRAESENTATIO TURMAE CLIENTIS

TRADITIO ET LOGISTICA

Societas magni aestimat qualitatem productorum, magnopere in introductionem apparatuum et peritorum provectorum investit, et omni ope nititur ut necessitatibus clientium domi et in terris externis satisfaciat.

Contenta grosse dividi possunt in: compositionem chemicam, limitem cessionis, limitem tensile, proprietatem impactus, et cetera.

Simulenter, societas etiam detectionem vitiorum et recoctionem aliasque curationes caloris in linea secundum necessitates emptorum perficere potest.

https://www.ytdrintl.com/

Litterae Electronicae:sales@ytdrgg.com

Tianjin YuantaiDerun Societas Fabricationis Tuborum Ferreorum, Ltd.officina tuborum ferreorum est ab probataEN/ASTM/ JISin productione et exportatione omnium generum tuborum quadratorum rectangularium, tuborum galvanizatorum, tuborum ERW sudatorum, tuborum spiralium, tuborum arcu submersorum sudatorum, tuborum sutura recta, tuborum sine suturis, spiralium chalybis colore obductarum, spiralium chalybis galvanizatorum, aliorumque productorum chalybis specializata. Cum commoda vectura, 190 chiliometra ab Aëroporto Internationali Capitali Pechinensi et 80 chiliometra a Xingang Tianjin distat.

Whatsapp: +8613682051821

Mitte nobis nuntium tuum:

-

Tubus ferreus olei VENDITIO TOTA

-

Tubus rotundus chalybis carbonis nigri laminatus calidus, altae protectionis contra corrosionem, conglutinatus

-

Involucrum API 5CT SMLS K55-N80

-

Tubus linearis API 5L SMLS X42-X70

-

Tubus ferreus vendibilis ASTM A53 A106 API 5L conglutinatus

-

Tubus Ferreus Parvus Api 5L X42/X46/X60/X70