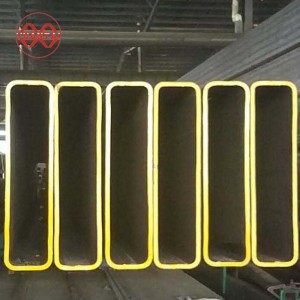

Introduction to square tube (round to square) process

Tianjin Yuantai Derun Group JCOE Φ 1420 unit can output specifications and caliber Φ 406mm to Φ 1420mm, with a maximum wall thickness of 50mm. After being put into production, it will make up for the gap in the Tianjin market of such products, which can significantly shorten the ordering period of ultra-large diameter, ultra-thick wall structure round tubes and square tube products. The double-sided submerged arc welding large straight welded pipe can be directly used for oil and gas transmission. JCOE steel pipe has been widely used in the national "West-East Gas Transmission" project. At the same time, it can be used as structural steel pipe in the construction of super high-rise steel structure projects. In addition, the "round to square" process can be used to process it into ultra-large diameter, ultra-thick wall rectangular steel pipe, which can be used in the field of large recreation facilities and heavy mechanical equipment manufacturing.

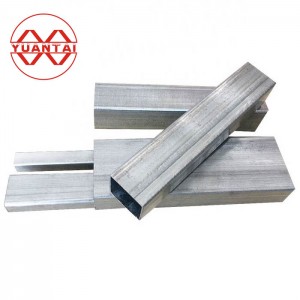

The "round to square" unit independently developed by Tianjin Yuantai Derun Group has the capacity to process the maximum diameter of 1000mm × 1000mm square tube, 800mm × The processing capacity of 1200mm rectangular tube with a maximum wall thickness of 50mm and super-large diameter and super-thick wall rectangular tube has been successfully supplied to the domestic market up to 900mm × 900mm × 46mm, outlet max. 800mm × 800mm × 36mm ultra-large diameter and ultra-thick wall products meet a variety of complex technical requirements of domestic and foreign users, including 400mm rectangular tube × 900mm × 30mm products also represent the leading level of "round to square" technology at home and abroad.

The third tallest building in the world - the super-high landmark skyscraper in Wuhan, China with a design height of 636 meters - Wuhan Greenland Center is a representative project of super-high steel structure supplied by Tianjin Yuantai Derun Group.

After years of process improvement, the outer arc of the large-diameter ultra-thick wall rectangular tube produced by the "round-to-square" process of Tianjin Yuantai Derun Group has successfully overcome the defects that are prone to crack during the round-to-square bending process and the difficulties in the control of the flatness of the tube surface during the "deformation" process, which can meet the requirements of relevant domestic and foreign standards for the product and the customer's special technical parameter control requirements. The product has been widely praised in key engineering projects exported to the Middle East, In China, it can also basically replace the "box column" products in the original assembled steel structure enterprises. Because the square tube products have only one weld, its structural stability is far better than the "box column" products welded from steel plates with four welds. This can be seen in the requirements that Party A specifies the use of "square tube" and prohibits the use of "box column" in some key foreign projects.

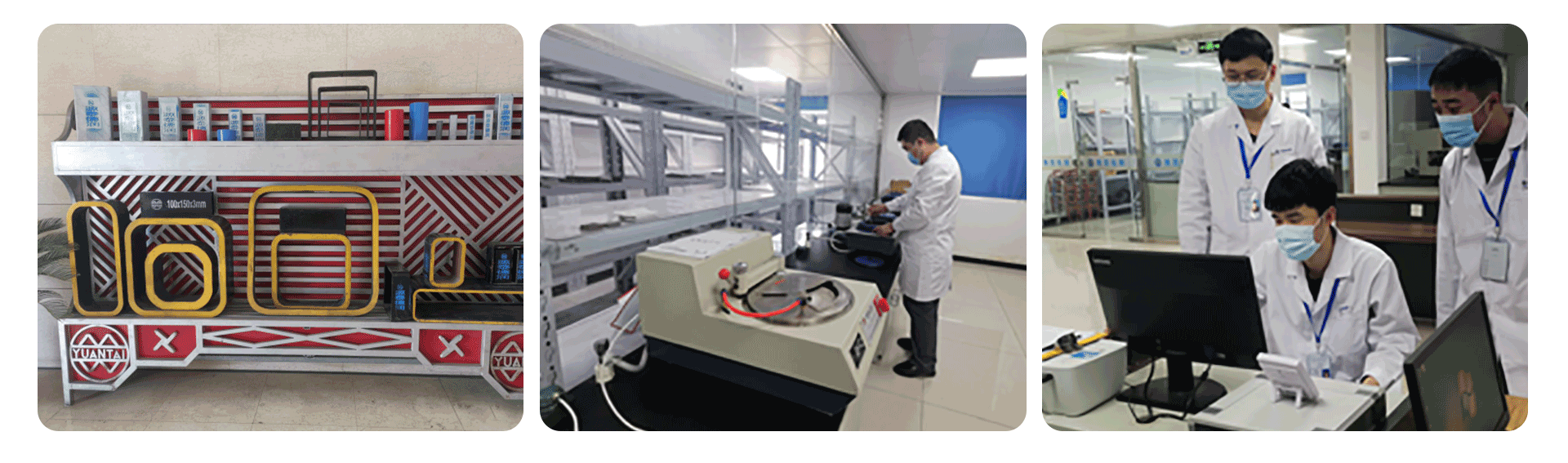

In terms of cold bending forming technology, Tianjin Yuantai Derun Group has nearly 20 years of accumulation and has the ability to customize special-shaped structural steel pipes according to customer requirements. The picture shows the "octagonal steel pipe" customized by a large amusement park in China. Due to the design parameters, it needs to be cold-formed at one time. Due to the requirements of the diameter and wall thickness of the product, the major manufacturers in China have inquired about it for more than three months. Finally, only Tianjin Yuantai Derun Group can meet its various requirements, and successfully produced nearly 3000 tons to complete all the supply services of the project alone.

Taking the "customized" route facing the market is the firm marketing strategy of Tianjin Yuantai Derun Group. For this reason, Tianjin Yuantai Derun Group, with the ultimate goal of "all square tube products Yuantai must be able to produce", insists on investing more than 50 million yuan a year in the research and development of new equipment, new molds and new processes. At present, it has introduced intelligent tempering equipment, which can be used to produce the outer arc rectangular square tube for glass curtain wall engineering, and can also be used for annealing stress relief or hot bending of square tube, It greatly enriches the processing capacity and the range of products that can be produced, and can meet customers' one-stop procurement requirements for structural steel pipes.

As we all know, box column is widely used in large steel structure buildings at home and abroad, and it has been popularized for many years abroad. Nowadays, more and more construction and design units use large rectangular tube instead of box column structure. With the increasing thickness of the former, it will fully cover the use of domestic box column in the near future.

At present, large square tube is extruded into square tube by submerged arc welding process with special equipment. Submerged arc welding is one of the mechanical welding methods with high production efficiency. Its full name is automatic submerged arc welding, also known as automatic arc welding under flux layer. The round to square tube made by this process has the following advantages:

1.High production efficiency

On the one hand, the conductive length of welding wire is shortened, and the current and current density are increased, so the arc penetration and welding wire deposition efficiency are greatly improved( On the other hand, due to the heat insulation effect of flux and slag, there is basically no heat radiation loss on the arc, and the spatter is also less. Although the heat loss for melting flux is increased, the total thermal efficiency is still greatly increased.

2.High weld quality

The welding parameters can be kept stable by automatic adjustment. The requirements for welder's technical level are not high. The weld composition is stable and the mechanical properties are good.

3.Good working conditions

In addition to reducing the labor intensity of manual welding operation, it has no arc radiation, which is the unique advantage of submerged arc welding.

4.Low processing cost

Usually, the processing cost of box column is as high as 1000 to 2000 yuan, while the processing cost of large rectangular tube is only a few hundred yuan, which is very cost-effective.

5.Safer to use

Compared with the two, the welding quantity of rectangular tube is much less than that of box column, and the welding quantity is greatly reduced.

(eg: the new landmark of Guangdong, Hong Kong and Macao, the 128 meter high super Ferris wheel "Shenzhen light" in Shenzhen, the main columns of Google new office building in Singapore, etc. are all large rectangular tube products that our group has remodeled from the factory.)

Specification of square and rectangular hollow sections

01 DERECT DEAL

We have been specialized in

producing steel for many years

- 02 COMPLETE

- SPECIFICATIONS

OD:10*10-1000*1000MM 10*15-800*1100MM

Thickness:0.5-60mm

Length:1-24M

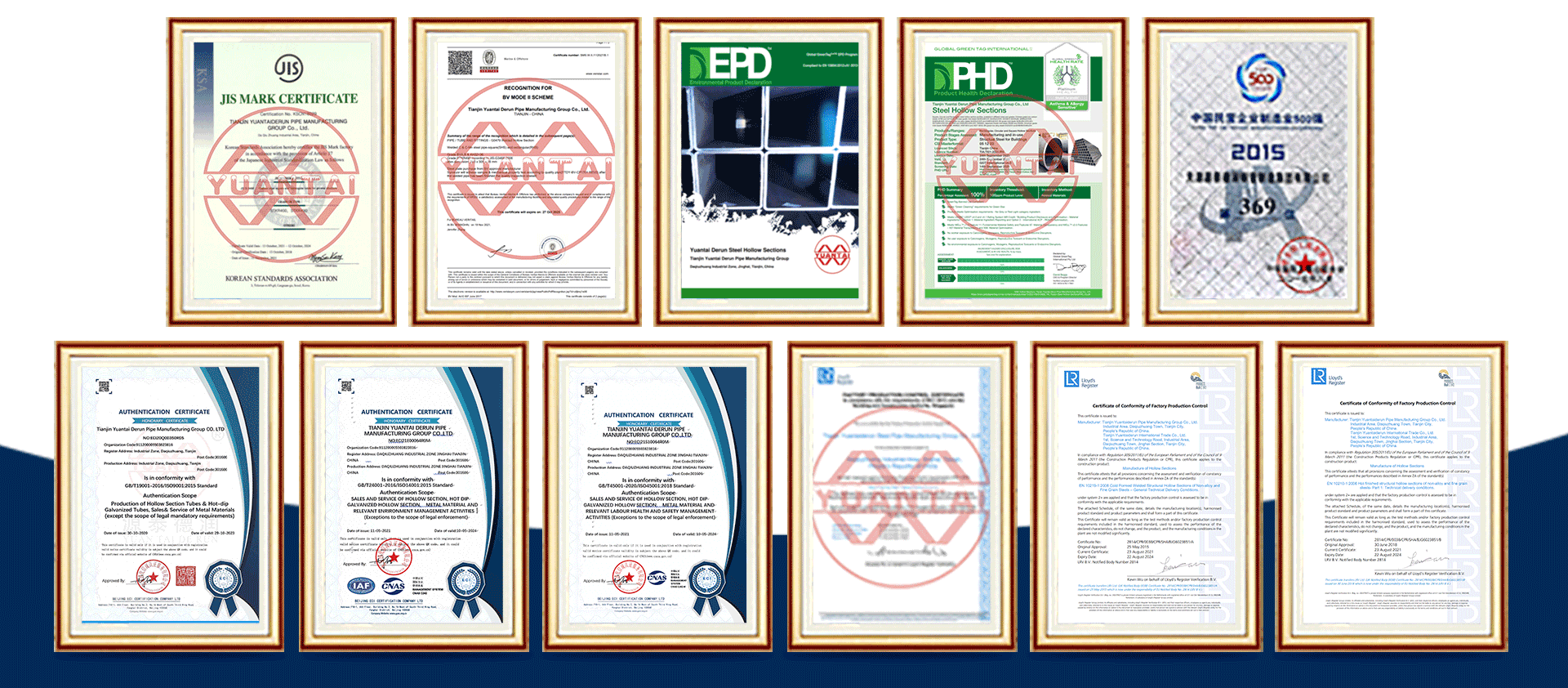

3 CERTIFICATION IS

COMPLETE

can produce steel pipe products of world

stardard,such as European standard,American standard,

Japanese standard,Astralian standard,natinal standard

and so on.

04 LARGE INVENTORY

Common specifications perennial inventory of

200000 tons

A: We are factory.

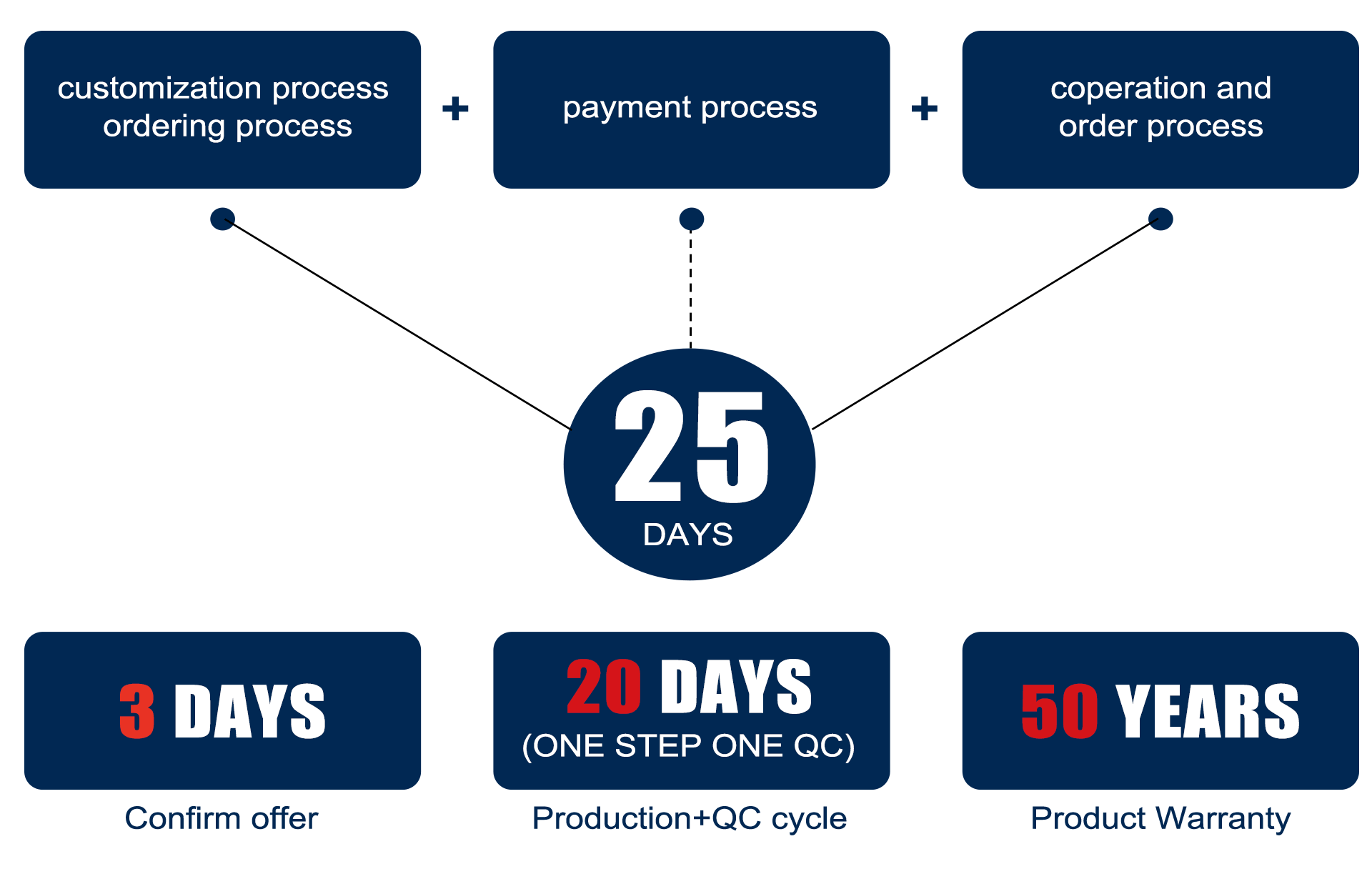

A: Generally it is 5-10 days if the goods are in stock. or it is 30 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge with the cost of freight paid by customer.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below

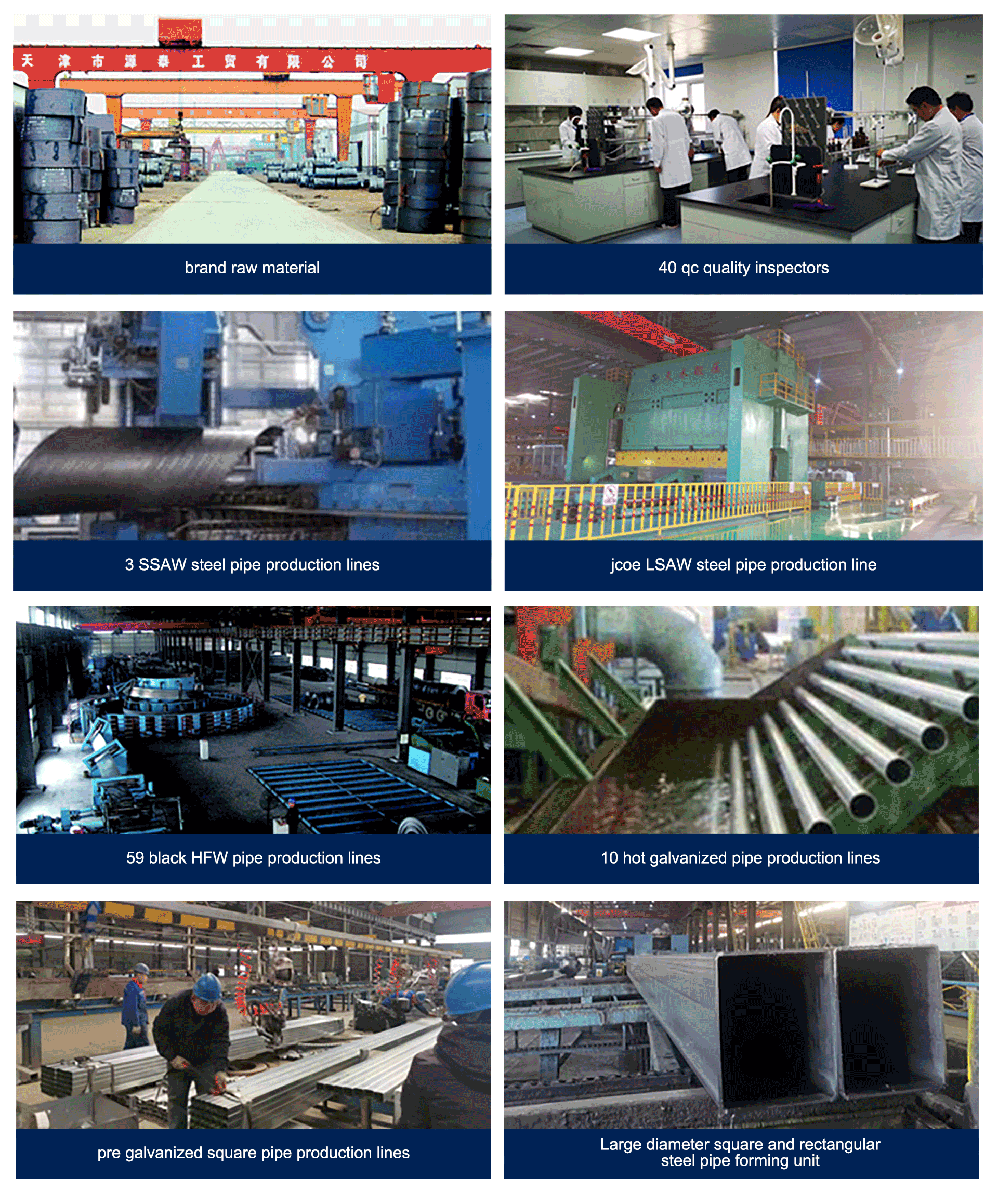

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821