Geméiss dem American Petroleum Institute Standard API SPEC 5CT1988 1. Editioun kann de Stolgrad vun API 5CT Uelegmantelrohren an zéng Typen agedeelt ginn, dorënner H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 a Q-125. Mir liwweren d'Mantelrohr & API 5CT K55 Mantelrohren zesumme mat Gewënn a Kupplung, oder mir bidden eis Produkter am Aklang mat de folgende Formen als Optioun un.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

API 5CT K55 Gehäuseröhrchen Spezifikatiounen

| API 5CT K55 Gehäuserohr Spezifikatiounen | ||

| OD | 10,3 mm - 2032 mm | |

| Standarden | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Längtberäich | 3-12M oder no Client Ufuerderungen | |

| Stolqualitéit (Gehäusequalitéiten, Réierqualitéiten) | Gr. A, Gr. B, Gr. C, X42, X52, X60, X65, X70 | |

| Aart vun der Schraufgewinde | Net verstäerkt Gewënnend (NUE), extern verstäerkt Gewënnend (EUE) | |

| Spezialitéiten |

| |

| Ennveraarbechtung | Extern Stuckend (EUE), Spannverbindung, PH6 (an gläichwäerteg Verbindungen), Integralverbindung (IJ) | |

API 5CT K55 Gehäuseschlauch Zuch- a Härtefuerderung

| Grupp | Grad | Typ | Gesamtdehnung ënner Belaaschtung % | Streckgrenz MPa | Zuchfestigkeit min. MPa | Häert maximal. | Spezifizéiert Wanddicke mm | Zulässlech Härtheetsvariatioun b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Minutt | max. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0,5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0,5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0,5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0,5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0,5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0,5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0,5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0,5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 bis 19.04 19.05 bis 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0,5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 bis 19.04 19.05 bis 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0,7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 ze 19.04 19.05 ze 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0,6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0,65 | 862 | 1034 | 931 | b | - | ≤ 12,70 12,71 bis 19,04 ≥ 19,05 | 3.0 4.0 5.0 |

| aAm Fall vun engem Sträit soll d'Rockwell C-Härtheetester am Laboratoire als Arbittermethod benotzt ginn. bEt gi keng Härtegrenze spezifizéiert, awer déi maximal Variatioun ass limitéiert am Aklang mat 7.8 an 7.9 vun der API Spec. 5CT. | ||||||||||

Dimensiounen vum K55-Gehäuse

| Gréissten vun de Päifmantelen, Gréissten vun den Uelegfeldmantelen a Gréissten vun der Drift vum Mantel | |

|---|---|

| Äusseren Duerchmiesser (Gréissten vun de Gehäuserohre) | 4 1/2"-20", (114,3-508 mm) |

| Standard Gehäusegréissten | 4 1/2"-20", (114,3-508 mm) |

| Fuedemtyp | Supporter Gewënngehäuse, Laangt ronnt Gewënngehäuse, Kuerzt ronnt Gewënngehäuse |

| Funktioun | Et kann d'Schlauchleitung schützen. |

Uelegröhrchen fir d'Pëtrols- an d'Äerdgasindustrie

| Numm vun de Päifen | Spezifikatioun | Stolqualitéit | Standard | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Pëtrolsmantel Päif | 127-508 | 5.21-16.66 | 6-12 | J55M55.K55. L80. N80P110. | API Spezifikatioun 5CT (8) |

| Pëtrolsréier | 26,7-114,3 | 2,87-16,00 Auer | 6-12 | J55. M55. K55. L80. N80. P110. | API Spezifikatioun 5CT (8) |

| Kupplung | 127-533.4 | 12,5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spezifikatioun 5CT (8) |

API 5CT K55 Gehäuse-Réier Eegeschafte

- API 5CT K55 Gehäuserohr gëtt mat enger fräier Längt vun 8m bis 13m op Basis vun der SY/T6194-96 Norm ugebueden. Si sinn awer och mat enger Längt vun op d'mannst 6m verfügbar an hir Quantitéit däerf net méi wéi 20% sinn.

- Deformatiounen, déi uewe genannt sinn, däerfen net op der äusserer Uewerfläch vun der API 5CT K55 Gehäuse-Réierkupplung optrieden.

- All Deformatioun wéi Hoerlinn, Trennung, Falten, Rëss oder Schuppen ass net akzeptabel souwuel op der bannenzeger wéi och op der baussenzeger Uewerfläch vum Produkt. All dës Mängel solle komplett ewechgeholl ginn an d'Entfernungsdéift däerf net méi wéi 12,5% vun der nomineller Wanddicke sinn.

- D'Uewerfläch vum Gewënn vun der Kupplung an dem API 5CT K55 Gehäuseschlauch soll glat sinn, ouni Grat, Tréinen oder aner Mängel, déi en negativen Afloss op d'Festigkeet an déi enk Verbindung kënnen hunn.

Et ass wichteg fir Ueleg- a Gasbetreiber, hir Produktiounsbuermantel mat kathodeschem Schutz virun Korrosioun ze schützen, & API 5CT Uelegfeldschläich déngen haaptsächlech fir den Transport vun Ueleg a Gaser.

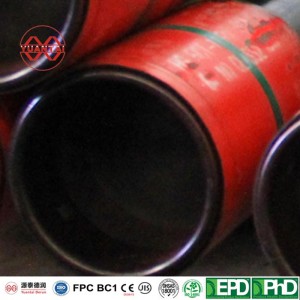

API 5CT Grad K55 Gehäuse-Réierstahl Faarfcode

| Numm | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Gehäuse | e hellgréngt Band | zwee hellgréng Bänner | e hellrout Band | e knallrout Band + e gréngt Band | e roude Band + e brongt Band | e hellwäisse Band |

| Kupplung | ganz gréng Kupplung + e wäisst Band | ganz gréng Kupplung | ganz rout Kupplung | ganz rout Kupplung + e gréngt Band | ganz rout Kupplung + e brongt Band | ganz wäiss Kupplung |

Spezifikatioune vun ISO/API-Gehäuse/API 5CT K55-Gehäuseschlauch

| Codea | Äusseren Duerchmiesser | Nenngewiicht (mat Fuedem an Kopplung) b,c | Wanddicke | Typ vun der Endveraarbechtung | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Pond/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9,5 | 114,3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114,3 | 15,63 | 5,69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114,3 | 17.26 | 6,35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13,5 | 114,3 | 20.09 | 7,37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114,3 | 22.47 | 8,56 | - | - | - | - | - | - | LB | LB |

| 5 | 11,5 | 127 | 17.11 | 5,59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 Auer | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7,52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26,79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31,85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34,53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35,86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139,7 | 20,83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15,5 | 139,7 | 23.07 | 6,98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139,7 | 25.3 | 7,72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139,7 | 29,76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139,7 | 34,23 | 10,54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168,28 | 29,76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168,28 | 35,72 | 8,94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168,28 | 41,67 | 10,59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168,28 | 47,62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177,8 | 25.3 | 5,87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177,8 | 29,76 | 6,91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177,8 | 34,23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177,8 | 38,69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177,8 | 43,16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177,8 | 47,62 | 11,51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177,8 | 52,09 | 12,65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193,68 | 35,72 | 7,62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193,68 | 39,29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29,7 | 193,68 | 44,2 | 9,52 | - | - | LB | LB | - | |||

| 7-5-8 | 33,7 | 193,68 | 50,15 | 10,92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193,68 | 58,04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42,8 | 193,68 | 63,69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45,3 | 193,68 | 67,41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193,68 | 70,09 | 15,88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219,08 | 35,72 | 6,71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219,08 | 41,67 | 7,72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219,08 | 47,62 | 8,94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219,08 | 53,57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219,08 | 59,53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219,08 | 65,48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219,08 | 72,92 | 14.15 Auer | - | - | - | LB | LB | LB | ||

| API 5CT Mantelrohr Codea | API 5CT Mantelrohr Äusseren Duerchmiesser | API 5CT Mantelrohr Nenngewiicht (mat Fuedem a Kopplung) b,c | API 5CT Mantelrohr Wanddicke | API 5CT Mantelrohr Endveraarbechtungstyp | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Pond/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32,3 | 244,48 | 48,07 | 7,92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244,48 | 53,57 | 8,94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244,48 | 59,53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43,5 | 244,48 | 64,73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244,48 | 69,94 | 11,99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53,5 | 244,48 | 79,62 | 13,84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58,4 | 244,48 | 86,91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32,75 | 273,05 | 48,74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40,5 | 273,05 | 60,27 | 8,89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45,5 | 273,05 | 67,71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273,05 | 75,9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55,5 | 273,05 | 82,59 | 12,57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60,7 | 273,05 | 90,33 | 13,84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65,7 | 273,05 | 97,77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298,45 | 62,5 | 8,46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298,45 | 69,94 | 9,53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298,45 | 80,36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298,45 | 89,29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339,72 | 71,43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54,5 | 339,72 | 81.1 | 9,65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339,72 | 90,78 | 10,92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339,72 | 101,19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339,72 | 107,15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406,4 | 96,73 | 9,53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406,4 | 111,61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406,4 | 125,01 | 12,57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87,5 | 473,08 | 130,21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139,89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106,5 | 508 | 158,49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197,93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Kuerz ronne Gewënn, L-Laang ronne Gewënn, B-Stützegewinde | ||||||||||||

| a. De Code gëtt fir d'Bestellreferenz benotzt. | ||||||||||||

| b. Dat nominellt Gewiicht vum Gewënn- a gekoppelte Gehäuse (Kolonn 2) gëtt nëmme als Referenz ugewisen. | ||||||||||||

| c. Martensitesche Chromstol (L80 9Cr an 13Cr) ënnerscheet sech vun Kuelestol a senger Dicht. Dat ugewise Gewiicht vum martensitesche Chromstol ass keen exakte Wäert. De Massekorrekturfaktor 0,989 kann benotzt ginn. | ||||||||||||

| d. Gehäuse aus Stolqualitéit C90, T95 an Q125 solle geméiss de Spezifikatiounen, dem Gewiicht an der Wanddicke aus der uewe genannter Tabelle oder Bestellung geliwwert ginn. | ||||||||||||

API 5CT K55 Chemesch Zesummesetzung

| Grupp | Grad | Typ | C | Mn | Mo | Cr | Net max. | Cu max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Minutt | max. | Minutt | max. | Minutt | max. | Minutt | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| R95 | - | - | 0,45 c | - | 1.9 | - | - | - | - | - | - | 0,03 | 0,03 | 0,45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - |

| L80 | 1 | - | 0,43 a | - | 1.9 | - | - | - | - | 0,25 | 0,35 | 0,03 | 0,03 | 0,45 | |

| L80 | 9Cr | - | 0,15 | 0,3 | 0,6 | 0,9 | 1.1 | 8 | 10 | 0,5 | 0,25 | 0,02 | 0,01 | 1 | |

| L80 | 13Cr | 0,15 | 0,22 | 0,25 | 1 | - | - | 12 | 14 | 0,5 | 0,25 | 0,02 | 0,01 | 1 | |

| C90 | 1 | - | 0,35 | - | 1.2 | 0,25 b | 0,85 | - | 1.5 | 0,99 | - | 0,02 | 0,01 | - | |

| T95 | 1 | - | 0,35 | - | 1.2 | 0,25 Deeg | 0,85 | 0,4 | 1.5 | 0,99 | - | 0,02 | 0,01 | - | |

| C110 | - | - | 0,35 | - | 1.2 | 0,25 | 1 | 0,4 | 1.5 | 0,99 | - | 0,02 | 0,005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0,030 e | 0,030 e | - |

| 4 | Q125 | 1 | - | 0,35 | 1,35 | - | 0,85 | - | 1.5 | 0,99 | - | 0,02 | 0,01 | - | |

| De Kuelestoffgehalt fir L80 däerf bis zu maximal 0,50 % erhéicht ginn, wann d'Produkt mat Ueleg ofgekillt gëtt. De Molybdängehalt fir Grad C90 Typ 1 huet keng Mindesttoleranz, wann d'Wanddicke manner wéi 17,78 mm ass. De Kuelestoffgehalt fir R95 däerf bis zu maximal 0,55 % erhéicht ginn, wann d'Produkt mat Ueleg gehäuscht gëtt. De Molybdängehalt fir T95 Typ 1 däerf op mindestens 0,15 % reduzéiert ginn, wann d'Wanddicke manner wéi 17,78 mm ass. Fir EW Grad P110 däerf de Phosphorgehalt maximal 0,020 % an de Schwefelgehalt maximal 0,010 % sinn. NL = keng Limit. Déi ugewise Elementer mussen an der Produktanalyse gemellt ginn. | |||||||||||||||

API 5CT k55 Gr. Mechanesch Eegeschaften

| API 5CT Gehäusestandard | Typ | API 5CT Gehäuse Zugfestigkeit MPa | API 5CT Gehäuse Streckgrenz MPa | API 5CT Gehäusehärte Max. |

|---|---|---|---|---|

| API Spezifikatioun 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

D'Firma leet groussen Wäert op d'Qualitéit vun de Produkter, investéiert staark an d'Aféierung vun fortgeschrattener Ausrüstung a Fachleit a mécht alles fir de Bedierfnesser vun de Clienten am In- an Ausland gerecht ze ginn.

Den Inhalt kann ongeféier opgedeelt ginn an: chemesch Zesummesetzung, Streckgrenz, Zugfestigkeit, Schlagfestigkeit, etc.

Gläichzäiteg kann d'Firma och Online-Feelerdetektioun an -Glühung an aner Wärmebehandlungsprozesser no de Bedierfnesser vum Client duerchféieren.

https://www.ytdrintl.com/

E-Mail:sales@ytdrgg.com

Tianjin YuantaiDerun Stolrohrfabrikatiounsgrupp Co., Ltd.ass eng zertifizéiert Stolrohrfabréck vunEN/ASTM/ JISspezialiséiert op d'Produktioun an den Export vun all Zorte vu quadratesche rechteckege Päifen, galvaniséierte Päifen, ERW geschweesste Päifen, Spiralpäifen, Tauchbogengeschweesste Päifen, geraden Nahtpäifen, nahtlosen Päifen, faarfbeschichtete Stahlspiralen, galvaniséierte Stahlspiralen an aner Stahlprodukter. Mat prakteschem Transport ass et 190 Kilometer vum Beijing Capital International Airport an 80 Kilometer vun Tianjin Xingang ewech.

WhatsApp: +8613682051821