Araka ny American Petroleum Institute Standard API SPEC 5CT1988 1st fanontana, ny vy kilasy ny API 5CT menaka casing sodina azo zaraina ho folo karazana, anisan'izany H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 ary Q-125. Izahay dia manome ny casing pipe & API 5CT K55 Casing Tubing miaraka amin'ny kofehy sy ny coupling, na manolotra ny vokatray izahay mifanaraka amin'ireto endrika manaraka ireto ho safidy.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

API 5CT K55 Casing Tubing Specifications

| API 5CT K55 CASING TUBING SPECIFICATIONS | ||

| OD | 10.3mm-2032mm | |

| Fenitra | API 5CT, API 5L, ASTM A53, ASTM A106 | |

| Halavany | 3-12M na araka ny takian'ny mpanjifa | |

| Kilasy vy (Naoty casing, naoty fantsona) | Gr.A,Gr.B,Gr.C,X42,X52,X60,X65,X70 | |

| Karazana kofehy visy | Ny faran'ny kofehy tsy misavoritaka (NUE), ny fiafaran'ny kofehy diso tafahoatra (EUE) | |

| specialties |

| |

| Famaranana | External Upset Ends (EUE), Flush Joint, PH6 (sy ireo fifandraisana mitovy aminy), Integral Joint (IJ) | |

API 5CT K55 Casing Tubing Tensile & fepetra takiana

| vondrona | kilasy | Type | Total elongation ambanin'ny entana % | tanjaka MPa | Henjana min. MPa | Ny hamafin'ny max. | Ny hatevin'ny rindrina voafaritra mm | Fiovaovan'ny hamafin'ny azo ekena b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max . | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12,70 12,71 hatramin'ny 19,04 19,05 hatramin'ny 25,39 ≥ 25,40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12,70 12,71 hatramin'ny 19,04 19,05 hatramin'ny 25,39 ≥ 25,40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 hatramin'ny 19.04 19.05 hatramin'ny 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 hatramin'ny 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aRaha misy fifandirana, ny fitiliana hamafin'ny laboratoara Rockwell C dia ampiasaina ho fomban'ny mpitsara. bTsy misy fetra ny hamafin'ny voafaritra, fa ny fiovaovana ambony indrindra dia voafetra araka ny 7.8 sy 7.9 ny API Spec. 5CT. | ||||||||||

K55 Casing Tubing refy

| Haben'ny fanasan-tsodina, Haben'ny fanasan-tsolika sy ny haben'ny tondra-drano | |

|---|---|

| Savaivony ivelany (Haben'ny fantsona casing) | 4 1/2"-20", (114.3-508mm) |

| Haben'ny Casing Standard | 4 1/2"-20", (114.3-508mm) |

| Karazana kofehy | Fonon'ny kofehy bozaka, Fonon'ny kofehy boribory lava, Fonon'ny kofehy boribory fohy |

| asa | Afaka miaro ny sodina tubing. |

Tube menaka ho an'ny orinasa solika sy entona voajanahary

| Anaran'ny fantsona | famaritana | Grade vy | Malagasy | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Sodina Casing Petroleum | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | API Spec 5CT (8) |

| Tubing Petroleum | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

| anankiray efa voavitrana | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

API 5CT K55 Casing Tubing Features

- Ny API 5CT K55 Casing Tubing dia atolotra miaraka amin'ny halavam-potoana maimaim-poana avy amin'ny 8m ka hatramin'ny 13m mifototra amin'ny fenitra SY/T6194-96. Tsy latsaky ny 6m ihany koa anefa ny halavany ary tsy tokony hihoatra ny 20% ny habeny.

- Ny deformation voalaza etsy ambony dia tsy avela hiseho amin'ny ety ivelany ny API 5CT K55 Casing Tubing coupling.

- Izay deformation toy ny tady volo, fisarahana, fiketronana, triatra na scab dia tsy azo ekena amin'ny lafiny anatiny sy ivelany amin'ny vokatra. Ireo kilema rehetra ireo dia tokony hesorina tanteraka ary ny halalin'ny nesorina dia tsy tokony hihoatra ny 12,5% amin'ny hatevin'ny rindrina.

- Ny tampon'ny kofehy mifamatotra sy ny API 5CT K55 Casing Tubing dia tokony ho malama tsy misy burr, rovitra na kilema hafa mety hisy fiantraikany ratsy amin'ny tanjaka sy ny fifandraisana akaiky.

Zava-dehibe ho an'ny mpandraharaha solika sy entona ny miaro ny vata famorian-dranon'izy ireo amin'ny harafesina miaraka amin'ny fiarovana cathodic & API 5CT OilField Tubing dia miasa voalohany amin'ny famindrana solika sy entona.

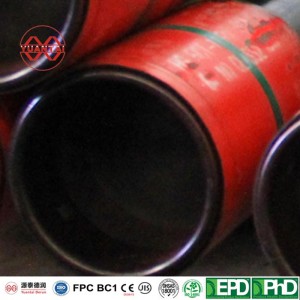

API 5CT Grade K55 Casing Tubing Steel Color Code

| Anarana | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | tarika maitso mavana | tarika maitso mavana roa | tarika mena mamiratra | tarika mena mamiratra + tarika maitso | tarika mena + tarika volontany | tarika fotsy mamirapiratra |

| anankiray efa voavitrana | coupling maitso manontolo + tarika fotsy | fitambarana maitso manontolo | coupling mena iray manontolo | coupling mena iray manontolo + tarika maitso | coupling mena iray manontolo + tarika volontany | fitambarana fotsy manontolo |

ISO/API casing/ API 5CT K55 Casing Tubing fepetra arahana

| Codea | Dia ivelany | Nominal lanja (miaraka amin'ny kofehy sy fifandraisana) b, c | Haben'ny rindrina | Karazana fanodinana faran'izay | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Casing pipe Codea | API 5CT Casing fantsona savaivony ivelany | API 5CT Casing sodina Nominal lanja (miaraka amin'ny kofehy ary mifamatotra) b, c | API 5CT Casing sodina hatevin'ny rindrina | API 5CT Casing fantsona Famaranana karazana fanodinana | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Tady boribory fohy, L-Tady boribory lava, kofehy B-Buttress | ||||||||||||

| a. Ny kaody dia ampiasaina amin'ny famandrihana reference. | ||||||||||||

| b. Ny lanja nomen'ny casing misy kofehy sy mitambatra (tsanganana 2) dia aseho ho fanondroana fotsiny. | ||||||||||||

| c. Ny vy chromium martensitic (L80 9Cr sy 13Cr) dia tsy mitovy amin'ny vy karbaona amin'ny hakitroky. Ny lanjan'ny martensitic chromium vy dia tsy sanda marina. Ny anton'ny fanitsiana faobe 0.989 dia azo ampiasaina. | ||||||||||||

| d. C90, T95 ary Q125 casing vy dia tokony omena araka ny fepetra arahana, ny lanjany sy ny hatevin'ny rindrina voatanisa ao amin'ny latabatra na ny baiko etsy ambony. | ||||||||||||

API 5CT K55 Famoronana simika

| vondrona | kilasy | Type | C | Mn | Mo | Cr | Tsy max. | Cu max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0,45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0,25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0,25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0,005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Ny votoatin'ny karbônina ho an'ny L80 dia mety hampitomboina hatramin'ny 0,50 % ambony indrindra raha toa ka vonoina menaka ny vokatra. b Ny votoatin'ny molybdène ho an'ny Grade C90 Type 1 dia tsy misy fandeferana kely indrindra raha latsaky ny 17,78 mm ny hatevin'ny rindrina. c Ny votoatin'ny karbaona ho an'ny R95 dia mety hampitomboina hatramin'ny 0,55% ambony indrindra raha toa ka vonoina menaka ny vokatra. d Ny votoatin'ny molybdène ho an'ny T95 Type 1 dia mety hidina ho 0,15% farafahakeliny raha latsaky ny 17,78 mm ny hatevin'ny rindrina. e Ho an'ny EW Grade P110, ny votoatin'ny phosphore dia tokony ho 0,020% ambony indrindra ary ny atiny solifara 0,010% ambony indrindra. NL = tsy misy fetra. Ny singa aseho dia tokony hotaterina amin'ny fanadihadiana ny vokatra. | |||||||||||||||

API 5CT k55 Gr. Toetra mekanika

| API 5CT Casing Standard | Type | API 5CT Casing Tensile Strength MPa | API 5CT Casing Yield Hery MPa | API 5CT Casing Hardness Max. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Ny orinasa dia manome lanja lehibe ny kalitaon'ny vokatra, mampiasa vola be amin'ny fampidirana fitaovana sy matihanina efa mandroso, ary manao izay rehetra ilain'ny mpanjifa eto an-toerana sy any ivelany.

Ny votoatiny dia azo zaraina amin'ny: firafitry ny simika, tanjaky ny vokatra, tanjaky ny tensile, fananana fiantraikany, sns

Amin'izany fotoana izany, ny orinasa dia afaka manatanteraka ihany koa ny fanaraha-maso ny lesoka amin'ny aterineto sy ny fanodinana ary ny fizotran'ny fitsaboana hafanana araka ny filan'ny mpanjifa.

https://www.ytdrintl.com/

mailaka:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.dia orinasa fantsona vy nohamarinin'nyEN/ASTM/ JISmanokana amin'ny famokarana sy ny fanondranana ny isan-karazany ny efamira mahitsizoro sodina, galvanized sodina, ERW welded sodina, miolakolaka sodina, sodina arka welded sodina, mahitsy seam sodina, seamless sodina, loko mifono vy coil, tafo vy coil sy ny vy products.With mety fitaterana, dia 190 kilometatra lavitra ny Beijing Renivohitra X Airport International sy 80jin kilometatra Tianjin.

Whatsapp: +8613682051821