Skont l-Istandard tal-Istitut Amerikan tal-Petroleum API SPEC 5CT1988 l-ewwel edizzjoni, il-grad tal-azzar tal-pajp tal-kisi taż-żejt API 5CT jista' jinqasam f'għaxar tipi, inklużi H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 u Q-125. Aħna nipprovdu l-pajp tal-kisi & API 5CT K55 Casing Tubing akkumpanjati bil-kamin u l-akkoppjar, jew noffru l-prodott tagħna skont il-forom li ġejjin għall-għażla.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Speċifikazzjonijiet tat-Tubi tal-Kisi API 5CT K55

| SPEĊIFIKAZZJONIJIET TAT-TUBING TAL-KISING API 5CT K55 | ||

| Daqsijiet Disponibbli | Dijametru ta' Barra ta' 2 3/8″, 2 7/8″ u 3 ½” | |

| Gradi | J55, J55-FBNAU, N80, L80, P110 | |

| Tubi | 1 1/4 “ – 2 1/16” Nom. | |

| Standards | SPEĊIFIKAZZJONI API 5CT | |

| Mudell fl-Użu Komuni | 2-3/8″, 2-7/8″, 3-1/2″, 4″, 4-1/2″ | |

| Firxa tat-Tul | R1(6.10-7.32m), R2(8.53-9.75m), R3(11.58-12.8m) | |

| Grad tal-Azzar (Gradi tal-Kisi, Gradi tat-Tubi) | J55, K55, N80-1, N80-Q, L80, P110 | |

| Tip ta' Ħajt tal-Kamin | Tarf bil-kamin mhux imqalleb (NUE), Tarf bil-kamin estern imqalleb (EUE) | |

| Speċjalitajiet |

| |

| Tmiem l-Irfinar | Truf Esterni Mqalleb (EUE), Ġonta Flush, PH6 (u konnessjonijiet ekwivalenti), Ġonta Integrali (IJ) | |

Rekwiżit tat-Tensjoni u l-Ebusija tat-Tubi tal-Kisi API 5CT K55

| Grupp | Grad | Tip | It-titwil totali taħt tagħbija % | Saħħa tar-rendiment MPa | Saħħa tat-tensjoni minima MPa | Ebusija massima. | Ħxuna tal-ħajt speċifikata mm | Varjazzjoni permessa tal-ebusija b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| minuta | massimu. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| Ċ90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 sa 19.04 19.05 sa 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 sa 19.04 19.05 sa 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| Ċ110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 sa 19.04 19.05 sa 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 sa 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aF'każ ta' tilwima, l-ittestjar tal-ebusija Rockwell C tal-laboratorju għandu jintuża bħala l-metodu ta' referenza. bM'hemm l-ebda limiti ta' ebusija speċifikati, iżda l-varjazzjoni massima hija ristretta skont 7.8 u 7.9 tal-API Spec. 5CT. | ||||||||||

Dimensjonijiet tat-Tubi tal-Kisi K55

| Daqsijiet tal-Kisi tal-Pajpijiet, Daqsijiet tal-Kisi tal-Qasam taż-Żejt u Daqsijiet tad-Drift tal-Kisi | |

|---|---|

| Dijametru ta' Barra (Daqsijiet tal-Pajpijiet tal-Kisi) | 4 1/2″-20″, (114.3-508mm) |

| Daqsijiet Standard tal-Kisi | 4 1/2″-20″, (114.3-508mm) |

| Tip ta' Ħajt | Kisi tal-ħajta tal-buttress, Kisi tal-ħajta tonda twila, Kisi tal-ħajta tonda qasira |

| Funzjoni | Jista' jipproteġi l-pajp tat-tubi. |

Tubu taż-Żejt għall-Industriji tal-Petrolju u l-Gass Naturali

| Isem tal-Pajpijiet | Speċifikazzjoni | Grad tal-Azzar | Standard | ||

|---|---|---|---|---|---|

| D | (S) | (T) | |||

| (mm) | (mm) | (m) | |||

| Pajp tal-Kisi tal-Petrolju | 127-508 | 5.21-16.66 | 6-12 | J55M55.K55. L80. N80P110. | Speċifikazzjoni tal-API 5CT (8) |

| Tubi tal-Petrolju | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | Speċifikazzjoni tal-API 5CT (8) |

| Igganċjar | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | Speċifikazzjoni tal-API 5CT (8) |

Karatteristiċi tat-Tubi tal-Kisi API 5CT K55

- It-Tubi tal-Kisi API 5CT K55 huma offruti b'firxa ta' tul liberu minn 8m sa 13m abbażi tal-istandard SY/T6194-96. Madankollu, huma wkoll disponibbli b'tul ta' mhux inqas minn 6m u l-kwantità tagħhom m'għandhiex tkun aktar minn 20%.

- Id-deformazzjonijiet imsemmija hawn fuq mhumiex permessi li jidhru fuq il-wiċċ ta' barra tal-akkoppjar tat-Tubi tal-Kisi API 5CT K55.

- Kwalunkwe deformazzjoni bħal linja tax-xagħar, separazzjoni, tikmix, xquq jew qoxra mhijiex aċċettabbli kemm fuq l-uċuħ ta' ġewwa kif ukoll ta' barra tal-prodott. Dawn id-difetti kollha għandhom jitneħħew kompletament u l-fond imneħħi m'għandux jaqbeż it-12.5% tal-ħxuna nominali tal-ħajt.

- Il-wiċċ tal-ħajta tal-akkoppjar u t-Tubi tal-Kisi tal-API 5CT K55 għandu jkun lixx mingħajr ebda tħin, tiċrita jew difetti oħra li jistgħu jkollhom impatt negattiv fuq is-saħħa u l-konnessjoni mill-qrib.

Huwa importanti għall-operaturi taż-żejt u l-gass li jipproteġu l-kisi tal-bir tal-produzzjoni tagħhom mill-korrużjoni bi protezzjoni katodika & API 5CT OilField Tubing iservi primarjament biex jittrasferixxi ż-żejt u l-gassijiet.

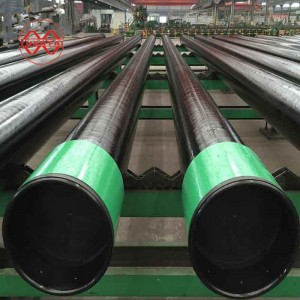

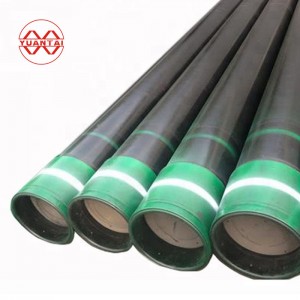

Kodiċi tal-Kulur tal-Azzar tat-Tubi tal-Kisi tal-API 5CT Grad K55

| Isem | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Kisi | strixxa ħadra jgħajjat | żewġ strixxi ħodor jgħajtu | strixxa ħamra jgħajjat | strixxa ħamra jgħajjat + strixxa ħadra | strixxa ħamra + strixxa kannella | strixxa bajda jgħajjat |

| Igganċjar | akkoppjar aħdar kollu + strixxa bajda | akkoppjar aħdar kollu | akkoppjar aħmar kollu | akkoppjar aħmar kollu + strixxa ħadra | akkoppjar aħmar kollu + strixxa kannella | akkoppjar abjad kollu |

Speċifikazzjonijiet tal-kisi ISO/API/Tubi tal-kisi API 5CT K55

| Kodea | Dijametru ta' barra | Piż nominali (bil-ħajta u akkoppjar) b,ċ | Ħxuna tal-Ħajt | Tip ta' pproċessar finali | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N801 | Ċ90d | P110 | Q125d | ||

| In | Lb/ft | K55 | Ċ95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| Kodiċi tal-pajp tal-kisi API 5CT | Pajp tal-kisi API 5CT Dijametru ta' barra | Pajp tal-kisi API 5CT Piż nominali (bil-ħajta u akkoppjar) b,ċ | Ħxuna tal-ħajt tal-pajp tal-kisi API 5CT | Tip ta' pproċessar tat-tarf tal-pajp tal-kisi API 5CT | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m² | mm | H40 | J55 | M65 | L80 | N80 | Ċ90d | P110 | Q125d | ||

| In | Lb/ft | K55 | Ċ95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Ħajta tonda qasira, L-Ħajta tonda twila, B-Ħajta ta' rinforz | ||||||||||||

| a. Il-kodiċi jintuża għar-referenza tal-ordni. | ||||||||||||

| b. Il-piż nominali tal-kisi bil-kamin u akkoppjat (kolonna 2) huwa muri għal referenza biss. | ||||||||||||

| c. L-azzar tal-kromju martensitiku (L80 9Cr u 13Cr) huwa differenti mill-azzar tal-karbonju fid-densità. Il-piż muri tal-azzar tal-kromju martensitiku mhuwiex valur eżatt. Jista' jintuża l-fattur ta' korrezzjoni tal-massa ta' 0.989. | ||||||||||||

| d. Il-kisi tal-azzar C90, T95 u Q125 għandu jiġi fornut skont l-ispeċifikazzjoni, il-piż u l-ħxuna tal-ħajt elenkati fit-tabella jew fl-ordni ta' hawn fuq. | ||||||||||||

Kompożizzjoni Kimika tal-API 5CT K55

| Grupp | Grad | Tip | C | Mn | Mo | Cr | Ni massimu. | Massimu ta' Cu. | P massimu. | S massimu. | Jekk massimu. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| minuta | massimu | minuta | massimu | minuta | massimu | minuta | massimu | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 ċ | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| Ċ90 | 1 | - | 0.35 | - | 1.2 | 0.25 biljun | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 jum | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| Ċ110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Il-kontenut ta' karbonju għal L80 jista' jiżdied sa massimu ta' 0.50% jekk il-prodott ikun imkessaħ biż-żejt. b Il-kontenut tal-molibdenu għall-Grad C90 Tip 1 m'għandu l-ebda tolleranza minima jekk il-ħxuna tal-ħajt hija inqas minn 17.78 mm. c Il-kontenut ta' karbonju għal R95 jista' jiżdied sa massimu ta' 0.55% jekk il-prodott ikun imkessaħ biż-żejt. d Il-kontenut tal-molibdenu għat-T95 Tip 1 jista' jitnaqqas għal minimu ta' 0.15% jekk il-ħxuna tal-ħajt tkun inqas minn 17.78 mm. e Għall-Grad EW P110, il-kontenut tal-fosfru għandu jkun massimu ta' 0.020% u l-kontenut tal-kubrit massimu ta' 0.010%. NL = bla limitu. L-elementi murija għandhom jiġu rrappurtati fl-analiżi tal-prodott. | |||||||||||||||

Proprjetajiet Mekkaniċi tal-API 5CT k55 Gr.

| Standard tal-Kisi tal-API 5CT | Tip | Qawwa tat-Tensile tal-Kisi tal-API 5CT MPa | Qawwa tar-Rendiment tal-Kisi tal-API 5CT MPa | Ebusija tal-Kisi tal-API 5CT Massimu. |

|---|---|---|---|---|

| SPEĊIFIKAZZJONI API 5CT | J55 | ≥517 | 379 ~ 552 | —- |

| K55 | ≥517 | ≥655 | — | |

| N80 | ≥689 | 552 ~ 758 | — | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | —- |

B'produzzjoni annwali ta' 5 miljun tunnellata, Yuantai Derun hija l-akbar manifattur ta' pajpijiet kwadri ERW, pajpijiet rettangolari, pajpijiet vojta minn ġewwa, pajpijiet galvanizzati u pajpijiet iwweldjati spirali fiċ-Ċina. Il-bejgħ annwali laħaq il-$15-il biljun. Yuantai Derun għandha 59 linja ta' produzzjoni ta' pajpijiet suwed ERW, 10 linji ta' produzzjoni ta' pajpijiet galvanizzati u 3 linji ta' produzzjoni ta' pajpijiet iwweldjati spirali. Pajpijiet kwadri 20 * 20 * 1mm sa 500 * 500 * 40MM, pajpijiet tal-azzar rettangolari 20 * 30 * 1.2mm sa 400 * 600 * 40MM, pajpijiet spirali Ø 219-1420mm jistgħu jkunu magħmula minn gradi ta' azzar minn Q (s) 195 sa Q (s) 345B / gr.a-gr.d. Yuantai Derun tista' tipproduċi tubi rettangolari kwadri skont ASTM A500, JIS g3466, en10219, din2240 u as1163. Yuantai Derun għandha l-akbar inventarju ta' tubi rettangolari kwadri fiċ-Ċina, li jista' jissodisfa d-domanda tax-xiri dirett tal-klijenti.

Merħba lil kulħadd biex tikkuntattja lil Yuantai Derun, E-mail:sales@ytdrgg.com, u impjant ta' spezzjoni ta' konnessjoni f'ħin reali jew żjara fil-fabbrika!

| Prodott | Api 5L X42/X52/X60/X70 |

| Standard | Api 5L |

| Grad | X42, X52, X60, X65, X70 |

| Teknika | Irrumblat fil-kesħa |

| Dijametru estern mm | 21.3mm2032mm |

| Piż mm | 0.5mm-60mm |

| Tul | 5.8m/6m/11.8m/12m jew kif meħtieġ |

| Wiċċ | Pittura sewda/Galvanizzata/Verniċ/Kisi 3LPE/Barra |

| Post tal-oriġini | Ċina (Kontinentali) |

| Applikazzjoni | 1. Pajp tal-Fluwidu |

| 2. Pajp taż-Żejt | |

| 3. Pajp tal-Gass | |

| 4. Tubi tal-Bojler | |

| 5. Pajp tal-Istruttura | |

| 6. Tubu tal-fertilizzant eċċ. | |

| Ippakkjar | Pajpijiet ta’ taħt it-8 pulzieri jkunu f’mazz. Pajpijiet ta’ fuq ikunu bl-ingrossa. |

| Termini Kummerċjali | FOB, CFR, CIF, CIP eċċ. |

| Terminu tal-Ħlas | 1.30% avvanz TT u l-bilanċ imħallas wara l-ispezzjoni |

| 2.LC mal-vista | |

| Ħin tal-Kunsinna | 7-30 jum tax-xogħol wara li tirċievi ħlas bil-quddiem jew LC |

SPETTAKLU TAL-ĦADDIEMA TAL-FABBRIKA

In-nisa mhumiex inferjuri għall-irġiel.

Il-persistenza konsistenti kisbet champion wieħed ta' kategorija

Iż-żmien jista’ jbiddel kollox, imma ż-żmien jista’ ma jbiddel xejn, pereżempju, il-qalb inizjali

Nies Yuantai jiġġieldu f'diversi postijiet

WIRI TAL-WORKSHOP TAL-FABBRIKA

PREŻENTAZZJONI TAT-TIM TAL-KLIJENTI

TWASSIL U LOĠISTIKA

Il-kumpanija tagħti importanza kbira lill-kwalità tal-prodotti, tinvesti ħafna fl-introduzzjoni ta' tagħmir u professjonisti avvanzati, u tagħmel minn kollox biex tissodisfa l-bżonnijiet tal-klijenti f'pajjiżhom u barra minn pajjiżhom.

Il-kontenut jista' jinqasam bejn wieħed u ieħor fi: kompożizzjoni kimika, saħħa tar-rendiment, saħħa tat-tensjoni, proprjetà tal-impatt, eċċ.

Fl-istess ħin, il-kumpanija tista' wkoll twettaq skoperta ta' difetti onlajn u ttemprar u proċessi oħra ta' trattament bis-sħana skont il-bżonnijiet tal-klijent.

https://www.ytdrintl.com/

Indirizz elettroniku:sales@ytdrgg.com

Tianjin YuantaiDerun Grupp tal-Manifattura tat-Tubi tal-Azzar Co., Ltd.hija fabbrika tal-pajpijiet tal-azzar iċċertifikata minnEN/ASTM/ JISspeċjalizzata fil-produzzjoni u l-esportazzjoni ta' kull tip ta' pajp rettangolari kwadru, pajp galvanizzat, pajp iwweldjat ERW, pajp spirali, pajp iwweldjat b'ark mgħaddas, pajp b'ħjata dritta, pajp mingħajr saldatura, kolja tal-azzar miksija bil-kulur, kolja tal-azzar galvanizzat u prodotti oħra tal-azzar. B'trasport konvenjenti, hija 190 kilometru 'l bogħod mill-Ajruport Internazzjonali Kapitali ta' Beijing u 80 kilometru 'l bogħod minn Tianjin Xingang.

Whatsapp:+8613682051821

Ibgħatilna l-messaġġ tiegħek:

-

Pajp tal-azzar taż-żejt BEJGĦ KOLLHA

-

Pajp tond tal-azzar iwweldjat bil-karbonju iswed irrumblat bis-sħana u b'protezzjoni għolja għall-korrużjoni

-

Kisi API 5CT SMLS K55-N80

-

Pajp tal-linja API 5L SMLS X42-X70

-

Pajp iwweldjat ASTM A53 A106 API 5L li jinbiegħ bis-sħana

-

Pajp tal-Linja tal-Azzar Żgħir Api 5L X42/X46/X60/X70