ERW welded steel pipe

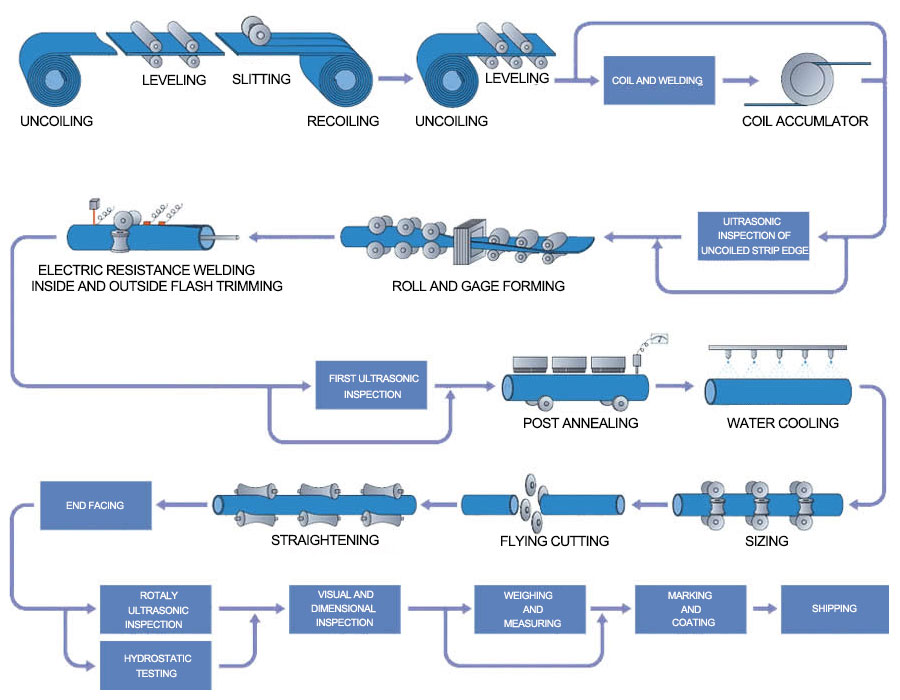

The manufacturing process of ERW steel pipes includes HFW. ERW welding includes low, medium, and high frequency welding, while HFW is particularly suitable for high-frequency resistance welding.

ERW pipe: resistance welded pipeOuter diameter (outer diameter): 10.3mm-609mm, thickness: 0.5-20mm or customized. For larger pipelines, submerged arc welding will be used for manufacturing. "

HFW pipe: high frequency welded pipe

What is HFW steel pipe?

It should be noted that HFW pipe is a kind of ERW pipe.

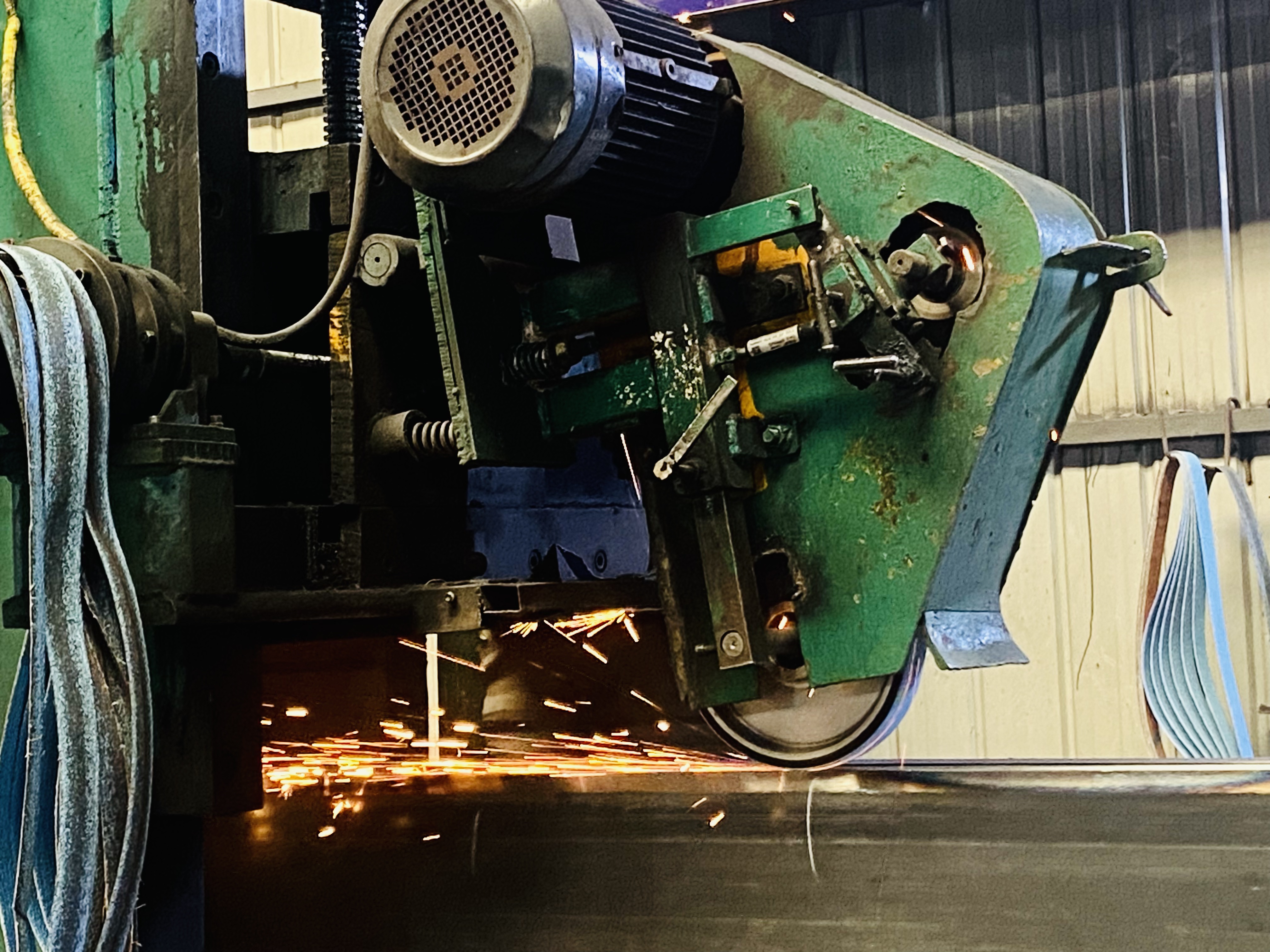

High frequency welded (HFW) steel pipe refers to ERW pipe with a welding current frequency equal to or greater than 70kHZ. Through the high frequency current welding resistance, the heat generated when contacting the object causes the surface of the object to be heated to a plastic state, and then forging is performed or not to achieve the combination of steel. HFW is a solid resistance heat energy. When high frequency current passes through a metal conductor, two special effects, skin effect and proximity effect, will occur. The HFW process uses the skin effect to concentrate on the surface of the steel object and the proximity effect to control the position and power of the high-frequency current flow path. Due to the high speed, the edges of the contacting plates can be heated and melted on the shore, and then extruded through the butt process.

It should be noted that the HFW tube is a type of ERW tube.

High-frequency welding (HFW) is a solid resistance heat energy. Through the high-frequency current welding resistance, heat is generated in the contact object, so that the surface of the object is heated to a plastic state, and then forged or not forged to achieve the combination of steel.

Application and advantages of ERW steel pipe

ERW stands for resistance welding, which has the characteristics of high production efficiency, low cost, material saving, and easy automation. Therefore, it is widely used in various industrial sectors such as aviation, aerospace, energy, electronics, automotive, and light industry, and is one of the important welding processes.

Advantages of HFW tube

During the welding process, HFW steel pipes do not require the addition of filler metal. Therefore, the welding speed is fast and the production efficiency is high. HFW pipes are widely used in oil and gas transportation, oil well pipelines, building structures, and various mechanical pipelines. However, the quality of HFW steel pipes is affected by various factors such as raw materials and processes. And production quality control has become difficult. So the yield and welding process still need to be continuously improved.

The difference between ERW (straight seam resistance welding) and HFW (high-frequency welding) is mainly the principle.

Resistance welding, as the name implies, is a method of welding by applying pressure through electrodes after the weldment is combined, and using the resistance heat generated by the current passing through the contact surface and adjacent areas of the joint. High-frequency welding: When high-frequency current passes through a metal conductor, two peculiar effects will be produced: skin effect and proximity effect. High-frequency welding uses these two effects to weld steel pipes. These two effects are the basis for realizing high-frequency welding of metals.

High-frequency welding uses the skin effect to concentrate the energy of high-frequency current on the surface of the workpiece; and uses the proximity effect to control the position and range of the high-frequency current flow path. The speed of the current is very fast. It can heat and melt the edges of adjacent steel plates in a very short time, and achieve docking through extrusion. Each has its own advantages and disadvantages. Generally, it is necessary to analyze and select according to the specific situation.

Post time: Jan-06-2025