Malinga ndi American Petroleum Institute Standard API SPEC 5CT1988 1st kope, chitsulo kalasi ya API 5CT mafuta casing chitoliro akhoza kugawidwa mu mitundu khumi, kuphatikizapo H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 ndi Q-1. Timapereka chitoliro cha casing & API 5CT K55 Casing Tubing limodzi ndi ulusi ndi kuphatikiza, kapena timapereka malonda athu molingana ndi mafomu otsatirawa kuti musankhe.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Mafotokozedwe a API 5CT K55 Casing Tubing

| API 5CT K55 CASING TUBING ZINTHU | ||

| OD | 10.3mm-2032mm | |

| Miyezo | API 5CT,API 5L,ASTM A53,ASTM A106 | |

| Utali Wautali | 3-12M kapena malinga ndi kasitomala amafuna | |

| Gulu la Zitsulo (Makalasi a Casing, Makalasi a Tubing) | Gr.A,Gr.B,Gr.C,X42,X52,X60,X65,X70 | |

| Mtundu wa Screw Thread | Non upset threaded end(NUE), External upset threaded end(EUE) | |

| Zapadera |

| |

| Kumaliza Kumaliza | External Upset Ends (EUE), Flush Joint, PH6 (ndi maulumikizidwe ofanana), Integral Joint (IJ) | |

API 5CT K55 Casing Tubing Tensile & Hardness Requirement

| Gulu | Gulu | Mtundu | Kutalikirana kwathunthu pansi pa katundu% | Zokolola mphamvu MPa | Mphamvu yolimba min. MPa | Kuuma kwa max. | Kunenepa kwa khoma mm | Kusiyanasiyana kovomerezeka kwa kuuma b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | Mtengo wa HRC | Mtengo wa HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| j55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Kr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 mpaka 19.04 19.05 mpaka 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 mpaka 19.04 19.05 mpaka 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 mpaka 19.04 19.05 mpaka 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 mpaka 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aPakakhala mkangano, kuyezetsa kuuma kwa labotale ya Rockwell C kudzagwiritsidwa ntchito ngati njira ya woweruza. bPalibe malire olimba omwe amatchulidwa, koma kusiyana kwakukulu kumaletsedwa malinga ndi 7.8 ndi 7.9 ya API Spec. 5CT. | ||||||||||

K55 Casing Tubing Dimensions

| Kukula kwa Pipe Casing, Makulidwe a Oilfield Casing & Makulidwe a Casing Drift | |

|---|---|

| Diameter Yakunja (Kukula kwa Pipe Casing) | 4 1/2"-20", (114.3-508mm) |

| Kukula kwa Casing Standard | 4 1/2"-20", (114.3-508mm) |

| Mtundu wa Ulusi | Chophimba cha ulusi wa buttress, Choyikapo ulusi wautali, Chophimba chachifupi chozungulira |

| Ntchito | Ikhoza kuteteza chitoliro cha chubu. |

Mafuta a Mafuta Opangira Mafuta ndi Gasi Wachilengedwe

| Dzina la Mapaipi | Kufotokozera | Kalasi yachitsulo | Standard | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Chitoliro cha Petroleum | 127-508 | 5.21-16.66 | 6-12 | j55. M55.K55. L80. N80. P110. | API Spec 5CT (8) |

| Mafuta a Tubing | 26.7-114.3 | 2.87-16.00 | 6-12 | j55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

| Kulumikizana | 127-533.4 | 12.5-15 | 6-12 | j55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

API 5CT K55 Casing Tubing Features

- API 5CT K55 Casing Tubing imaperekedwa ndi utali waulere kuchokera ku 8m mpaka 13m pamaziko a SY/T6194-96 chizolowezi. Komabe, imapezekanso osachepera 6m kutalika ndipo kuchuluka kwake kuyenera kukhala kosapitilira 20%.

- Zopindika zomwe tazitchula pamwambapa siziloledwa kuwonekera kunja kwa API 5CT K55 Casing Tubing coupling.

- Kupindika kulikonse monga tsitsi, kupatukana, kukwapula, mng'alu kapena nkhanambo sikuvomerezeka mkati ndi kunja kwa mankhwala. Zowonongeka zonsezi ziyenera kuchotsedwa kwathunthu ndipo kuya kochotsedwa sikuyenera kupitirira 12.5% ya makulidwe a khoma.

- Pamwamba pa ulusi wophatikizana ndi API 5CT K55 Casing Tubing iyenera kukhala yosalala popanda burr, kung'ambika kapena zolakwika zina zomwe zingakhale ndi zotsatira zoyipa pamphamvu ndi kulumikizana kwapafupi.

Ndikofunikira kuti ogwiritsa ntchito mafuta ndi gasi ateteze zopangira zawo kuti zisawonongeke ndi chitetezo cha cathodic & API 5CT OilField Tubing makamaka imathandizira kusamutsa mafuta ndi mpweya.

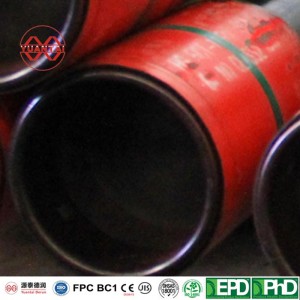

API 5CT Grade K55 Casing Tubing Steel Color Code

| Dzina | j55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | gulu lobiriwira lowala | magulu awiri obiriwira owala | gulu lofiira lofiira | gulu lofiira lofiira + gulu lobiriwira | gulu lofiira + gulu lofiirira | gulu loyera lowala |

| Kulumikizana | cholumikizira chobiriwira chonse + gulu loyera | kugwirizana konse kobiriwira | kugwirizana konse kofiira | kugwirizana konse kofiira + gulu lobiriwira | kugwirizana konse kofiira + gulu lofiirira | kugwirizana konse koyera |

ISO/API casing/ API 5CT K55 Casing Tubing specifications

| Kodi | Outer Dia | Kulemera mwadzina (ndi thread ndi kugwirizana) b, c | Makulidwe a Khoma | Mapeto processing mtundu | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | j55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Casing pipe Codea | API 5CT Casing chitoliro M'mimba mwake | API 5CT Casing chitoliro mwadzina kulemera (ndi thread ndi kugwirizana) b,c | API 5CT Casing chitoliro Wall makulidwe | API 5CT Casing chitoliro End processing mtundu | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | j55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| Ulusi Waufupi Wozungulira wa S, Ulusi Wautali Wautali wa L, Ulusi wa B-Buttress | ||||||||||||

| a. Code imagwiritsidwa ntchito poyitanitsa zidziwitso. | ||||||||||||

| b. Kulemera mwadzina kwa casing yolumikizidwa ndi ulusi (gawo 2) kumangowonetsedwa kokha. | ||||||||||||

| c. Martensitic chromium steel (L80 9Cr ndi 13Cr) imasiyana ndi chitsulo cha carbon mu kachulukidwe. Kulemera kowonetsedwa kwachitsulo cha martensitic chromium si mtengo weniweni. Kuwongolera kwakukulu 0.989 kungagwiritsidwe ntchito. | ||||||||||||

| d. C90, T95 ndi Q125 zitsulo kalasi casing ayenera kuperekedwa malinga ndi specifications, kulemera ndi makulidwe khoma zolembedwa pa tebulo pamwamba kapena dongosolo. | ||||||||||||

API 5CT K55 Chemical Composition

| Gulu | Gulu | Mtundu | C | Mn | Mo | Cr | Ndi max. | Ku max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| j55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 ndi | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Kr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Kr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25b ku | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25d ku | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 ndi | 0.030 ndi | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Mpweya wa L80 wa L80 ukhoza kuwonjezeka kufika pa 0.50 % pamlingo waukulu ngati mankhwalawo atsekedwa ndi mafuta. b Zomwe zili molybdenum za Gulu la C90 Type 1 zilibe kulekerera kochepa ngati makulidwe a khoma ndi ochepera 17.78 mm. c Mpweya wa kaboni wa R95 ukhoza kuonjezedwa kufika pa 0.55 % pamlingo waukulu ngati mankhwalawo azimitsidwa ndi mafuta. d Zomwe zili molybdenum za T95 Type 1 zitha kuchepetsedwa mpaka 0.15 % osachepera ngati makulidwe a khoma ndi osakwana 17.78 mm. e Kwa EW Grade P110, phosphorous yomwe ili pamwambayi ikhale 0.020 % pazipita ndi sulfure 0.010 % pazipita. NL = palibe malire. Zinthu zomwe zikuwonetsedwa zidzafotokozedwa pakuwunika kwazinthu. | |||||||||||||||

API 5CT k55 Gr. Mechanical Properties

| API 5CT Casing Standard | Mtundu | API 5CT Casing Tensile Strength MPa | API 5CT Casing Yield Mphamvu MPa | API 5CT Casing Hardness Max. |

|---|---|---|---|---|

| API SPEC 5CT | j55 | ≥517 | 379-552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552-758 | --- | |

| L80(13Cr) | ≥655 | 552-655 | ≤241HB | |

| P110 | ≥862 | 758-965 | ---- |

Kampaniyo imayika kufunikira kwakukulu kumtundu wazinthu, imayika ndalama zambiri poyambitsa zida zapamwamba ndi akatswiri, ndipo imapita kukakwaniritsa zosowa za makasitomala kunyumba ndi kunja.

Zomwe zilimo zitha kugawidwa m'magulu awiri: mankhwala, mphamvu zokolola, kulimba kwamphamvu, katundu wamphamvu, etc

Nthawi yomweyo, kampaniyo imathanso kuzindikira zolakwika pa intaneti ndikuwongolera ndi njira zina zochizira kutentha malinga ndi zosowa za makasitomala.

https://www.ytdrintl.com/

Imelo :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.ndi zitsulo chitoliro fakitale mbiri yabwino ndiEN/Chithunzi cha ASTM/ JISokhazikika kupanga ndi katundu wa mitundu yonse ya lalikulu amakona anayi chitoliro, kanasonkhezereka chitoliro, ERW welded chitoliro, ozungulira chitoliro, kumizidwa arc welded chitoliro, molunjika msoko chitoliro, chitoliro opanda msoko, mtundu TACHIMATA zitsulo koyilo, kanasonkhezereka zitsulo koyilo ndi zina zitsulo products.With zoyendera yabwino, ndi makilomita 190 kutali ndi Beijing Tingan International makilomita 80 kuchokera Beijing International Airport.

Watsapp: +8613682051821