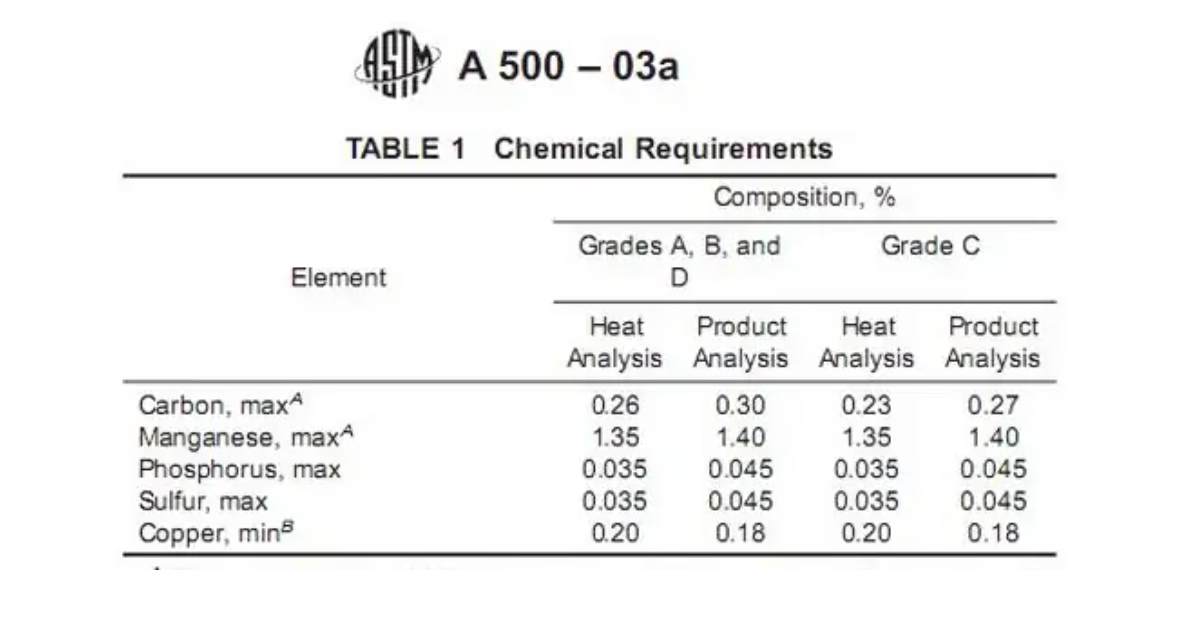

[A500] The chemical composition of A500 steel according to American astm standard is shown in the following figure:

The tensile strength of A500 steel is 400MPa, and the yield strength is 290MPa;

Compared with the national trademark Q295B and the reference standard GB/T 1591-1994 Low-alloy High-strength Structural Steel, Q295B is a low-alloy high-strength structural steel with good plasticity, weldability and impact toughness, as well as good cold and hot workability, low and medium temperature properties, and certain corrosion resistance. Q295B can be used to manufacture stamping parts of vehicles, building structural parts, medium and low pressure chemical vessels and low pressure boiler drums, sheet stamping parts, oil pipelines, oil storage tanks and projects with low temperature requirements.

A common problem is the difference between A500 and A513 steel pipe pile materials when they come. Customers often assume that the specifications are interchangeable, but when we study the specifications in depth, we see that there are significant differences.

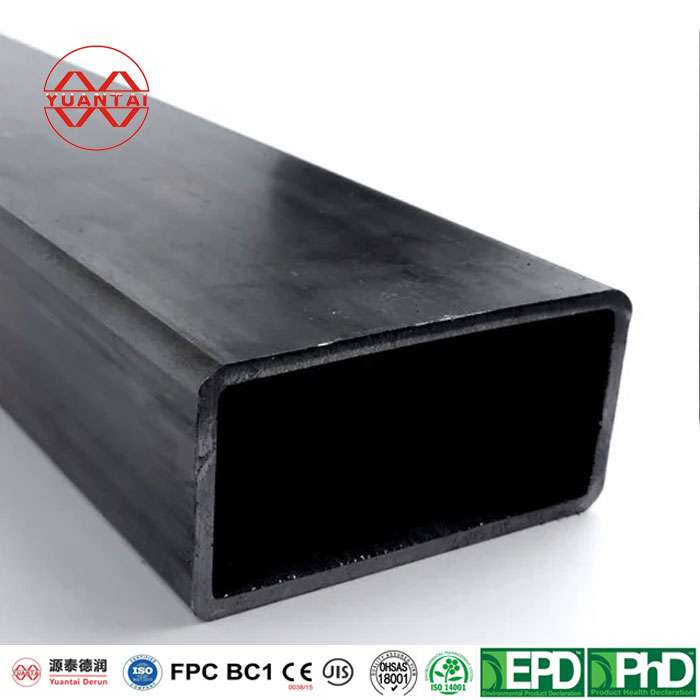

What is A500 steel pipe pile?

A500 steel pipe pile has many different names, and its shape is mostly square, rectangular and round pipe. It is also called structural pipe, or high-speed steel (or hollow structural steel). A500 steel pipe products are mostly used in applications requiring bearing. Due to its unique performance, A500 steel pipe is often used in buildings. When you order A500 steel pipe from the factory, the material test report not only shows the chemical composition of the steel coil used to manufacture the steel pipe, but also shows the relevant physical parameters such as impact, tensile and elongation. The report of physical properties is one of the main differences between A500 and A513 materials.

What is A513 steel pipe pile?

A513 steel pipe pile mechanical oil pipe, which requires more strict tolerance, does not involve the load-bearing performance of the material itself, and is mostly used in consumer-based applications. Applications of A513 can include recreational vehicles, mower handles or mechanical components.

ASTM A513 is an American standard steel

It should be the standard number of the material, resistance welded carbon steel and alloy steel mechanical steel pipe.

Chemical composition of A513 steel pipe:

carbon

c

0.18~0.23

silicon

si

0.15~0.35

manganese

mn

0.30~0.60

sulfur

s

:≤0.050

phosphorus

p

:≤0.040

chromium

cr:≤0.25

nickel

ni:≤0.25

copper

cu:≤0.25

Group overview

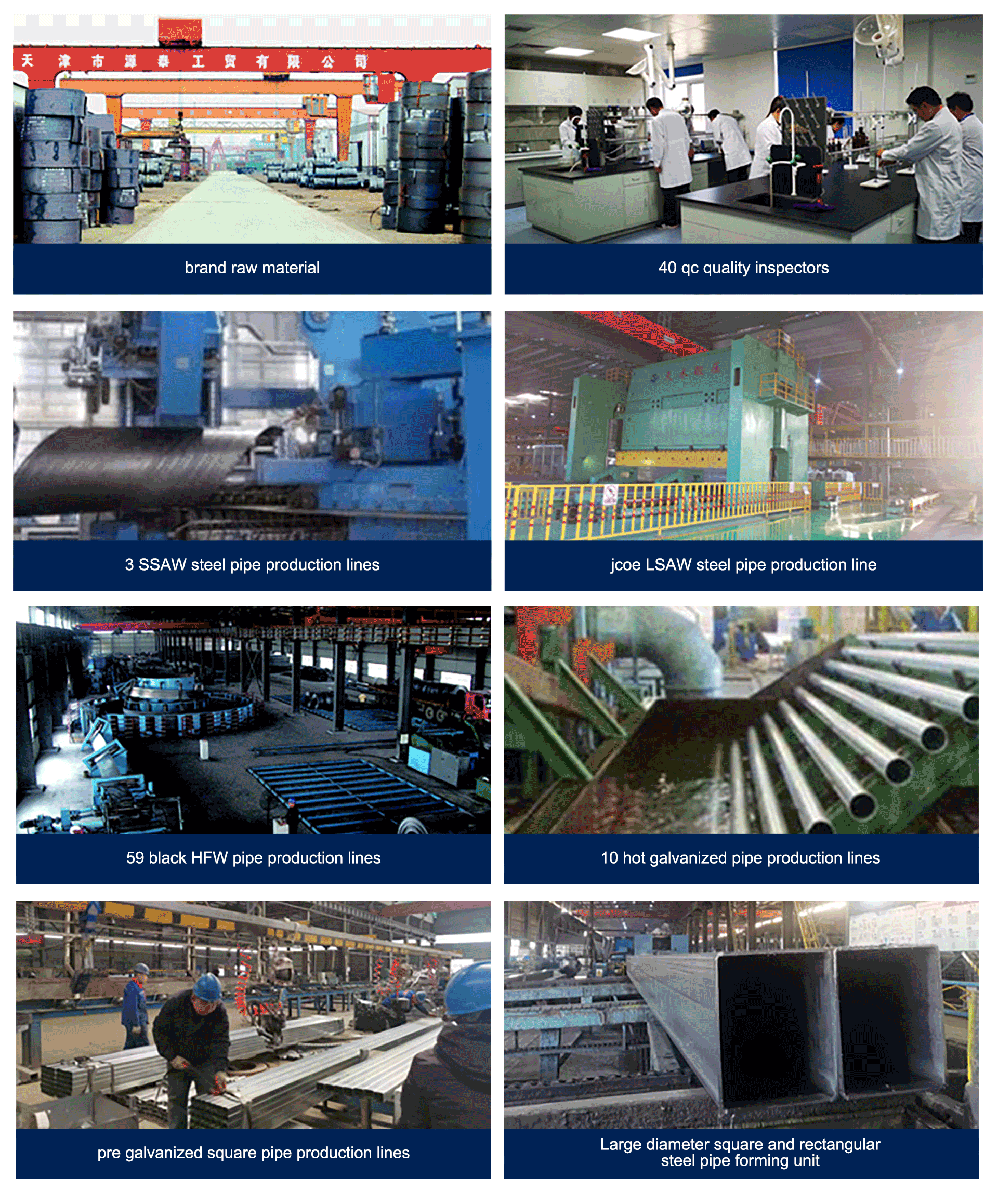

With an annual output of 10 million tons per year, Tianjin Yuantai Derun steel pipe manufacturing group is the largest manufacturer of Structural steel pipe, rectangular pipes, hollow section, galvanized pipes, LSAW steel tube and spiral tube in China.Annual sales reached 15 billion US dollars.

Yuantai Derun has 59 black ERW tubing production lines, 10 hot dip galvanized pipe production lines and 3 spiral welded steel pipe production lines.1 JCOE STEEL PIPE production line,6 pre galvanized steel tube production lines.

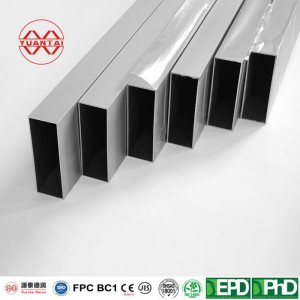

Square pipe outer diameter: 10 * 10 * 0.5 MM to 1000 * 1000 * 60 MM

rectangular steel pipe outer diameter:10 * 15 * 0.5mm to 800 * 1100 * 60MM,

LSAW steel pipe: Φ 355.6-2000mm,THICKNESS:0.5-60MM

spiral pipe :Φ 219-2032mm,THICKNESS:0.5-60MM

seamless pipe: Φ 21.3-820mm,THICKNESS:0.5-60MM。

Yuantai Derun can produce steel pipes conforming to ASTM A500/A501, JIS G3466, EN10219/10210, DIN2240 and AS1163. Yuantai Derun has the largest STEEL tube inventory 200000 tons in China, which can meet the direct purchase needs of customers. Welcome to contact Yuantai Derun, e-mail: sales@ytdrgg.com , real-time connection factory inspection or factory visit!

Specification of square and rectangular hollow sections

| OD(MM) | THICKNESS(MM) | OD(MM) | THICKNESS(MM) | OD(MM) | THICKNESS(MM) | OD(MM) | THICKNESS(MM) |

| 20*20 | 1.3 | 60*120 80*100 90*90 | 1.50 | 180*180 | 3 | 300*800 400*700 550*550 500*600 | |

| 1.4 | 1.70 | 3.5-3.75 | 9.5-9.75 | ||||

| 1.5 | 1.80 | 4.5-4.75 | 11.5-11.75 | ||||

| 1.7 | 2.00 | 5.5-7.75 | 12-13.75 | ||||

| 1.8 | 2.20 | 9.5-9.75 | 15-50 | ||||

| 2.0 | 2.5-4.0 | 11.5-11.75 | |||||

| 20*30 25*25 | 1.3 | 4.25-4.75 | 12.0-25.0 | ||||

| 1.4 | 5.0-6.3 | 100*300 150*250 200*200 | 2.75 | 300*900 400*800 600*600 500*700 | |||

| 1.5 | 7.5-8 | 3.0-4.0 | 9.5-9.75 | ||||

| 1.7 | 50*150 60*140 80*120 100*100 | 1.50 | 4.5-9.75 | 11.5-11.75 | |||

| 1.8 | 1.70 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 2.00 | 12.5-12.75 | 15-50 | ||||

| 2.2 | 2.20 | 13.5-13.75 | |||||

| 2.5-3.0 | 2.5-2.75 | 15.5-30 | |||||

| 20*40 25*40 30*30 30*40 | 1.3 | 3.0-4.75 | 150*300 200*250 | 3.75 | 300*1000 400*900 500*800 600*700 650*650 | ||

| 1.4 | 5.5-6.3 | 4.5-4.75 | |||||

| 1.5 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-16 | 9.5-9.75 | 12-13.75 | ||||

| 2.0 | 60*160 80*140 100*120 | 2.50 | 11.5-11.75 | 15-50 | |||

| 2.2 | 2.75 | 13.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 200*300 250*250 | 3.75 | 400*1000 500*900 600*800 700*700 | |||

| 3.25-4.0 | 5.5-6.3 | 4.5-4.75 | |||||

| 25*50 30*50 30*60 40*40 40*50 40*60 50*50 | 1.3 | 7.5-7.75 | 5.5-6.3 | 9.5-9.75 | |||

| 1.4 | 9.5-16 | 7.5-7.75 | 11.5-11.75 | ||||

| 1.5 | 75*150 | 2.50 | 9.5-9.75 | 12-13.75 | |||

| 1.7 | 2.75 | 11.5-11.75 | 15-50 | ||||

| 1.8 | 3.0-3.75 | 12-13.75 | |||||

| 2.0 | 4.5-4.75 | 15.5-30 | |||||

| 2.2 | 5.5-6.3 | 200*400 250*350 300*300 | 4.5-6.3 | 500*1000 600*900 700*800 750*750 | |||

| 2.5-3.0 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 3.25-4.0 | 9.5-16 | 9.5-9.75 | 11.5-11.75 | ||||

| 4.25-4.75 | 80*160 120*120 | 2.50 | 11.5-11.75 | 12-13.75 | |||

| 5.0-5.75 | 2.75 | 12-13.75 | 15-50 | ||||

| 5.75-6.3 | 3.0-4.75 | 15.5-30 | |||||

| 40*80 50*70 50*80 60*60 | 1.3 | 5.5-6.3 | 200*500 250*450 300*400 350*350 | 5.5-6.3 | 500*1100 600*900 700*800 750*750 | ||

| 1.5 | 7.5-7.75 | 7.5-7.75 | 9.5-9.75 | ||||

| 1.7 | 9.5-9.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 1.8 | 11.5-20 | 11.5-11.75 | 12-13.75 | ||||

| 2.0 | 100*150 | 2.50 | 12-13.75 | 15-50 | |||

| 2.2 | 2.75 | 15.5-30 | |||||

| 2.5-3.0 | 3.0-4.75 | 280*280 | 5.5-6.3 | 600*1100 700*1000 800*900 850*850 | |||

| 3.25-4.0 | 5.5-6.3 | 7.5-7.75 | 9.5-9.75 | ||||

| 4.25-4.75 | 7.5-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 40*100 60*80 70*70 | 1.3 | 11.5-20 | 12-13.75 | 15-50 | |||

| 1.5 | 100*200 120*180 150*150 | 2.50 | 15.5-30 | ||||

| 1.7 | 2.75 | 350*400 300*450 | 7.5-7.75 | 700*1100 800*1000 900*900 | |||

| 1.8 | 3.0-7.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 2.0 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 2.2 | 11.5-20 | 12-13.75 | 15-50 | ||||

| 2.5-3.0 | 100*250 150*200 | 3.00 | 15.5-30 | ||||

| 3.25-4.0 | 3.25-3.75 | 200*600 300*500 400*400 | 7.5-7.75 | 800*1100 900*1000 950*950 | |||

| 4.25-4.75 | 4.25-4.75 | 9.5-9.75 | 11.5-11.75 | ||||

| 5.0-6.3 | 9.5-9.75 | 11.5-11.75 | 12-13.75 | ||||

| 50*100 60*90 60*100 75*75 80*80 | 1.3 | 11.5-11.75 | 12-13.75 | 15-50 | |||

| 1.5 | 12.25 | 15.5-40 | |||||

| 1.7 | 140*140 | 3.0-3.75 | 300*600 400*500 400*400 | 7.5-7.75 | 900*1100 1000*1000 800*1200 | ||

| 1.8 | 4.5-6.3 | 9.5-9.75 | |||||

| 2.0 | 7.5-7.75 | 11.5-11.75 | 20-60 | ||||

| 2.2 | 9.5-9.75 | 12-13.75 | |||||

| 2.5-3.0 | 11.5-25 | 15.5-40 | |||||

| 3.25-4.0 | 160*160 | 3.00 | 400*600 500*500 | 9.5-9.75 | 1100*1000 1100*1100 | ||

| 4.25-4.75 | 3.5-3.75 | 11.5-11.75 | 20-60 | ||||

| 5.0-5.75 | 4.25-7.75 | 12-13.75 | |||||

| 7.5-8 | 9.5-25 | 15.5-40 |

A: We are factory.

A: Generally it is 5-10 days if the goods are in stock. or it is 30 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge with the cost of freight paid by customer.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below

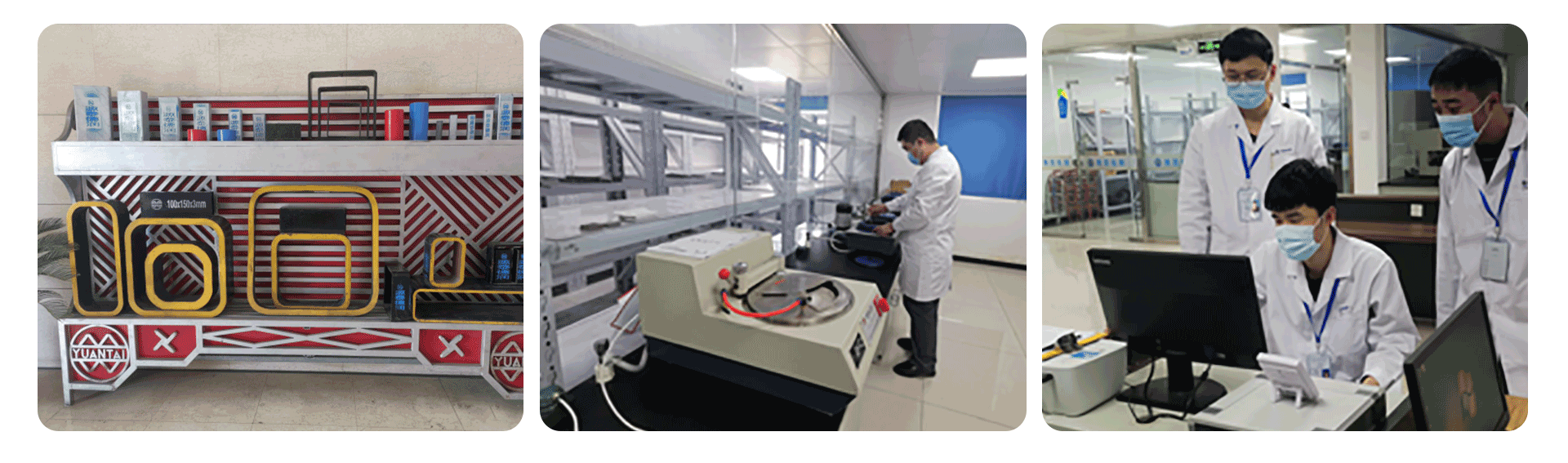

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821

Send your message to us:

-

Hot dip galvanized square tube for building structure

-

Hot dip galvanized square tube for briage

-

Hot dip galvanized square tube for airport

-

Hot dip galvanized square pipe for tower crane manufacture

-

Hot dip galvanized square pipe for road construction

-

Hot dip galvanized square pipe for prefabricated steel construction

-

Hot dip galvanized square pipe for photovoltaic project

-

Hot dip galvanized square pipe for large venues

-

Hot dip galvanized square pipe for high speed use

-

Hot dip galvanized square pipe for gymnasium

-

Hot dip galvanized square pipe for guardrail

-

Hot dip galvanized square pipe for glass curtain wall works

-

Hot dip galvanized square pipe for automobile manufacture

-

Galvanized square steel tube 100mm*100mm

-

European standard hot dip galvanized square pipe manufacturer

-

DIAMETER 50*50MM GALVANIZED SQUARE STEEL PIPE