YuantaiDerunsquare rectangular chubhu ine anopfuura makumi matanhatu nematatu patents, ayo anosangana nemaindasitiri zviyero kumba nekune dzimwe nyika. Chigadzirwa chacho chapfuura zvinopfuura mazana maviri ekuongorora zvinongedzo kudzora mhando yechigadzirwa.

"Zvakasimba usarega pombi yesimbi isina kukodzera kupinda mumusika".

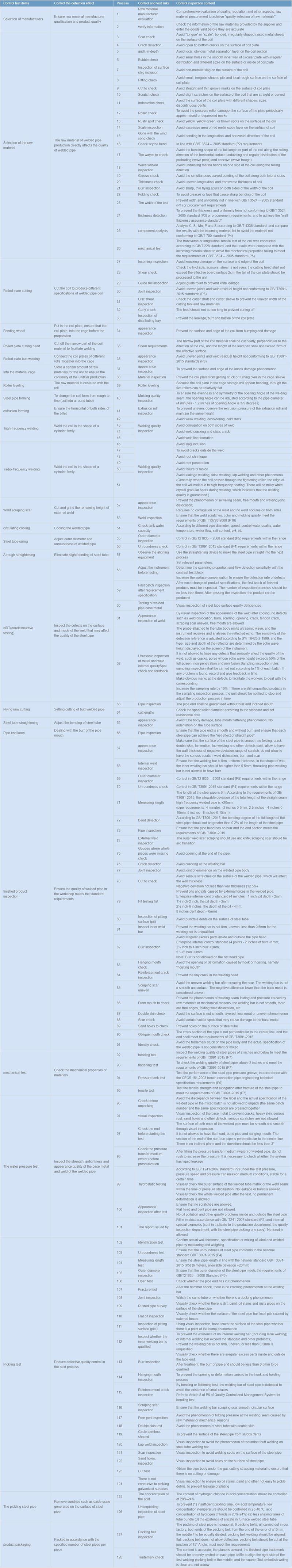

| Kudzora bvunzo zvinhu | Dzora maitiro ekuona | Process | Kudzora uye test link | Kudzora kuongorora zvinyorwa |

| Kusarudzwa kwevagadziri | Ita shuwa kuti raw material mugadziri anokodzera uye chigadzirwa mhando | 1 | Raw material mugadziri evaluation | Kuongororwa kwakadzama kwemhando, mukurumbira uye zvimwe zvinhu, kuwanikwa kwezvinhu zvakasvibirira kuti uwane "kusarudzwa kwemhando yezvigadzirwa" |

| 2 | simbisa ruzivo | Tarisa ruzivo rwezvakagadzirwa zvakapihwa nemutengesi uye pinda muyadhi yezvinhu zvisati zvaitika | ||

| Kusarudzwa kwezvinhu zvakasvibiswa | Iyo mbishi ye welded pombi kugadzirwa inokanganisa zvakananga kunaka kwe welded pombi | 3 | Scar check | Dzivisa "rurimi" kana "chiyero", akasungwa, asina kuumbwa akasimudzwa masheets esimbi pamusoro pecoil. |

| 4 | Kuona mutswe | Dzivisa kuvhurika kuzasi kwemuromo kutsemuka pamusoro pecoil plate | ||

| 5 | odhita-yakadzama | Dzivisa yemunharaunda, pachena simbi kupatsanura layer pane coil chikamu | ||

| 6 | Bubble cheki | Dzivisa maburi madiki mumadziro akatsetseka emukati edenderedzwa ndiro ine kugovera kusingaenzaniswi uye hukuru hwakasiyana pamusoro kana mukati mecoil plate. | ||

| 7 | Kuongororwa kwepamusoro slag kubatanidzwa | Dzivisa asiri-metallic slag pamusoro peiyo coil | ||

| 8 | Pitting check | Dzivisa makomba madiki, asina kurongeka uye nzvimbo yakakasharara pamusoro pemakoiri plate | ||

| 9 | Cheka kutarisa | Dzivisa mavara akatwasuka uye akatetepa egorofu pamusoro pecoil plate | ||

| 10 | Scratch check | Dzivisa kukwenya kudiki pamusoro peiyo coil yakatwasuka kana yakakombama | ||

| 11 | Indentation cheki | Dzivisa pamusoro peiyo coil plate ine akasiyana maumbirwo, saizi, discontinuous dents | ||

| 12 | Roller cheki | Kuti udzivise kukuvara kwekumanikidza roller, iyo pamusoro peplate nguva nenguva inoratidzika yakasimudzwa kana yakaora mwoyo mamakisi | ||

| 13 | Rusty spot check | Dzivisa mavara eyero, yero-girinhi, kana mashava pamusoro pecoil | ||

| 14 | Scale kuongorora | Dzivisa nzvimbo yakawandisa yered metal oxide layer pamusoro pecoil | ||

| 15 | Gone with the wind song check | Dzivisa kukotama mune longitudinal uye yakatwasuka nzira yecoil | ||

| 16 | Tarisa scythe bend | Zvinoenderana neGB/T 3524 -- 2005 standard (P2) zvinodiwa | ||

| 17 | Mafungu ekutarisa | Dzivisa chimiro chekupeta chehurefu hwakazara kana chikamu checoil parutivi rwekutenderedza kwenzvimbo yakachinjika inotenderedza uye kugadzika kugovera kweinobudikira (wave peak) uye concave (wave trough) | ||

| 18 | Wave wrinkle kuongorora | Dzivisa kunyungudika marina anokotama kune rimwe divi rekoiri achitevedza nzira inomonereka | ||

| 19 | Groove check | Dzivisa kukotama kwakakombama panguva imwe chete yekoiri nemativi ese eparutivi | ||

| 20 | Kuongorora ukobvu | Dzivisa kusaenzana longitudinal uye kuchinjika ukobvu hwecoil | ||

| 21 | Burr kuongorora | Dzivisa zvinopinza, zvitete zvinobhururuka zvinobhururuka kumativi ose maviri ehupamhi hwekoiri | ||

| 22 | Kupeta cheki | Kuti udzivise kukwenya kana makumbo anokonzera kukotama kwakapinza kwecoil | ||

| 23 | Upamhi hwebvunzo | Dzivirira hupamhi uye kufanana kusingaenderane neGB/T 3524 -- 2005 standard (P4) kana zvinodiwa zvekutenga. | ||

| 24 | kuona ukobvu | Kudzivirira ukobvu uye kufanana kubva mukusaenderana neGB/T 3524 -- 2005 standard (P3) kana zvinodiwa zvekutenga, uye kuzadzisa "wall thickness assurance standard" | ||

| 25 | chikamu chekuongorora | Ongorora C, Si, Mn, P uye S zvinoenderana neGB/T 4336 yakajairwa, uye enzanisa mibairo nerunyorwa rwezvinhu zvinouya kudzivirira izvo zvisingaenderane neGB/T 700 standard (P4) | ||

| 26 | mechanical test | Iyo yakachinjika kana longitudinal tensile bvunzo yecoil yakaitwa zvinoenderana neGB/T 228 yakajairwa, uye mibairo yacho yakaenzaniswa nebepa rezvinhu zvinopinda kudzivirira iyo mechaniki zvivakwa kutadza kuzadzisa zvinodiwa zveGB/T 3524 -- 2005 standard (P5). | ||

| Yakakungurutswa ndiro yekucheka | Cheka iyo coil kuti ibudise zvakasiyana-siyana zve welded pombi coil | 27 | Incoming inspection | Dzivisa kugogodza kukanganisa pamusoro uye kumucheto kwecoil |

| 28 | Shear cheki | Tarisa iyo hydraulic scissors, shear haina kana, musoro wekucheka haufanire kupfuura inoshanda bhodhi pamusoro 2cm, muswe wecoil plate unofanirwa kugadziridzwa kune iyo unit. | ||

| 29 | Guide roll kuongorora | Gadzirisa roller yemutungamiri kudzivirira kubuda kwebanga | ||

| 30 | Kuongorora pamwe chete | Dzivisa majoini asina kuenzana uye weld yakasara kureba isingaenderane neGB/ T3091-2015 zviyero (P8) | ||

| 31 | Disc shear kuongorora | Tarisa cutter shaft uye cutter sleeve kudzivirira hupamhi husina kuenzana hwekucheka chishandiso uye mbishi | ||

| 32 | Curly cheki | Chikafu hachifanirwe kunge chakareba kuti chidzivirire kumonereka | ||

| 33 | Kuongororwa kwekugovera tray | Dzivirira kubuda, burr uye buckle yecoil plate | ||

| Kudyisa vhiri | Isa mundiro yecoil, simbisa kuti coil ndiro, mukeji isati yagadzirira | 34 | kuongorora chitarisiko | Dzivirira pamusoro uye kumucheto kwecoil kubva pakuputsika uye kukuvara |

| Yakakungurutswa ndiro yekucheka musoro | Cheka chikamu chakamanikana checoil zvinhu kuti zvifambise welding | 35 | Shear zvinodiwa | Iyo yakamanikana chikamu cheiyo coil zvinhu ichachekwa zvakanaka, perpendicular kugwara rekoiri, uye kureba kwechikamu chinotungamira hachipfuure 2cm yenzvimbo inoshanda. |

| Yakakungurutswa ndiro butt welding | Batanidza mahwendefa ecoil emapumburu akasiyana Pamwe chete mukeji | 36 | kuongorora chitarisiko | Dzivisa majoini asina kuenzana uye weld yakasara kureba isingaenderane neGB/ T3091-2015 zviyero (P8) |

| Mukeji yezvinhu | Chengetedza humwe huwandu hwezvigadzirwa zveyuniti kuti uve nechokwadi chekuenderera kweiyo unitCar kugadzirwa | 37 | kuongorora chitarisiko | Kudzivirira pamusoro uye kumucheto kwekugogodza kukuvadza chiitiko |

| 38 | Kuongorora kwezvinhu | Dzivirira kuti coil plate isabatike kana kupinduka mucheshi sleeve | ||

| Roller leveling | Iyo mbishi inoiswa pakati nemupumburu | 39 | Roller leveling | Nekuti iyo coil ndiro mukeji yekuchengetera ichaita seyakakotama, kuburikidza nema roller mashanu anogona kunge akati sandarara |

| Simbi pombi kugadzira | Kushandura fomu recoil kubva pakushata kuenda kune yakanaka (coil kuita chubhu yakatenderera) | 40 | Molding quality kuongorora | Kuti ive nechokwadi chekuenzana uye symmetry yekuvhura Angle yewelding seam, iyo yekuvhura Angle inogona kugadziriswa zvinoenderana nedhayamita yepombi. (Maminetsi mana - 1.2 inches yekuvhura Angle ndeye 3-5 madhigirii) |

| extrusion kugadzira | Ita shuwa kuti yakatwasuka mativi ese ebhillet | 41 | Extrusion roll kuongorora | Kuti udzivise kusaenzana, cherechedza iyo extrusion pressure ye extrusion roll uye chengetedza hurefu hwakafanana |

| high-frequency welding | Weld coil muchimiro checylinder zvakasimba | 42 | Welding quality yekuongorora | Dzivisa kupera simba welding, desoldering, inotonhora stack |

| 43 | Dzivisa corrugation pamativi ese e weld | |||

| 44 | Dzivisa weld kuputika uye static crack | |||

| 45 | Dzivisa weld line kuumbwa | |||

| redhiyo-frequency welding | Weld coil muchimiro checylinder zvakasimba | 46 | Welding quality yekuongorora | Dzivisa slag kubatanidzwa |

| 47 | Kudzivirira kutsemuka kunze kwe weld | |||

| 48 | Dzivisa kudzikira kwemidzi | |||

| 49 | Dzivisa kupinda kwemidzi | |||

| 50 | Dzivisa kukundikana kwefusion | |||

| 51 | Dzivisa leakage welding, welding yenhema, lap welding uye zvimwe zviitiko. (Kazhinji, kana coil inopfuura nepainosimbisa roller, kumucheto kwecoil kunonyunguduka nekuda kwekudziya kwakanyanya. Pachave nemukaka chena crystal granular spark panguva yewelding, izvo zvinoratidza kuti welding quality inovimbiswa.) | |||

| Weld scraping vanga | Cheka uye geya kukwirira kwasara kwekunze weld | 52 | kuongorora chitarisiko | Dzivirira chiitiko che swiveling seam, muromo wakasununguka uye welding joint dislocation; Izvo hazvidi corrugation ye weld uye hapana weld nodules pamativi ese. |

| 53 | Weld kuongorora | Ita shuwa kuti weld scratches, ruvara uye kuumbwa kwemhando zvinosangana nezvinodiwa zveGB/ T13793-2008 (P10) | ||

| kutenderera kutonhora | Kutonhodza pombi yakasungwa | 54 | Tarisa tangi yemvura kugona | Zvinoenderana neyakasiyana pombi dhayamita, kumhanya, kudzora mhando yemvura, tembiricha yemvura, kuyerera kwemvura, munyu wemukati, pH, nezvimwe |

| Simbi chubhu saizi | Rongedza dhayamita rekunze uye kusatenderera kwepombi yakashongedzwa | 55 | Kuongorora kwekunze kwedhayamita | Kudzora muGB/T21835 -- 2008 yakajairwa (P5) zvinodiwa mukati mechikamu |

| 56 | Unroundness check | Kudzora muGB/ T3091-2015 chiyero (P4) zvinodiwa mukati meiyo renji | ||

| Kutwasanuka kwakakasharara | Bvisa kukotama zvishoma kwechubhu yesimbi | 57 | Tarisa midziyo yekubatanidza | Shandisa chigadziro chekururamisa kugadzira pombi yesimbi yakananga mune inotevera maitiro |

| NDT (nondestructive test) | Ongorora kukanganisa kwepamusoro uye mukati me weld iyo inogona kukanganisa kunaka kwepombi yesimbi | 58 | Rongedza chiridzwa usati waedza | Seta ma parameter akakodzera; Sarudza chikamu chekuongorora uye kukanganisa kwekuona kunzwisiswa neyakasiyana bvunzo block; Wedzera muripo wepamusoro kuti uve nechokwadi chekuonekwa kwehurema |

| 59 | Chekutanga batch ongororo mushure mekutsiviwa kutaurwa | Mushure mekuchinja kwega kwega kwezvakatemwa zvechigadzirwa, batch yekutanga yezvigadzirwa zvakapedzwa inofanira kuongororwa. Nhamba yematavi ekuongorora inofanira kunge isiri pasi pematatu. Mushure mekupfuura kuongororwa, chigadzirwa chinogona kugadzirwa | ||

| 60 | Kuedzwa kwe welded pipe base metal | Kuongororwa kwekuona kwesimbi chubhu pamusoro pehuhu husina kunaka | ||

| 61 | Kuonekwa kwekuongorora weld | Nekutarisa kwekutarisa kwechimiro che weld mushure mekutonhora, hapana chakaremara senge weld dislocation, kupisa, mavanga, kuvhurika, kutsemuka, tendon crack, kukwenya vanga risina kuenzana, muromo wakasununguka unobvumidzwa. | ||

| 62 | Ultrasonic kuongororwa kwesimbi uye weld yemukati qualitySpot cheki uye mhinduro | Iyo probe yakasungirirwa kumuviri wechubhu inoburitsa ultrasonic wave, uye chiridzwa chinogamuchira uye chinoongorora iyo inoratidzwa echo. Kunzwa kwekutarisa kwekutarisa kunogadziriswa zvinoenderana neSY/ T6423.2-1999, uye mhando, saizi uye kudzika kweiyo reflector inotarwa neiyo echo wave urefu inoratidzwa pachiratidziro chechiridzwa. Hazvibvumirwi kuva nezvikanganiso zvinokanganisa zvakanyanya kunaka kweweld, zvakadai sekutsemuka, pores ayo echo wave urefu inopfuura 50% yehwindo rakazara, risina kupinda mukati uye risina fusion.Mitemo yekuongorora sampuli: kuongorora sampling kuchaitwa maererano ne1% yebatch imwe neimwe. Kana paine dambudziko rawanikwa, rekodha uye upe mhinduro nenguva. Ita mamaki akajeka pane zvakakanganisika kufambisa vashandi kuti vatarise zvinoenderana; Wedzera sampling rate ne10%. Kana pachine zvigadzirwa zvisina kukodzera mukuita sampling yekuongorora, iyo unit inofanirwa kuziviswa kumira uye kugadzirisa maitiro ekugadzira nenguva. | ||

| Flying saw cutting | Kugadzika kutema butt-weld pipe | 63 | Kuongorora kwepombi | Iyo pombi inopera ichave yakavimbiswa isina burr uye yakarerekera muromo |

| 64 | cheka kureba | Tarisa iyo yekumhanyisa roller dhayamita zvinoenderana neyakajairwa uye isa data inonzwisisika | ||

| Simbi chubhu kutwasanudza | Gadzirisa kukotama kwechubhu yesimbi | 65 | kuongorora chitarisiko | Dzivisa kukuvadzwa kwechubhu yemuviri, chubhu muromo flattening chiitiko; Hapana indentation pane chubhu pamusoro |

| Pipe end keep | Kutarisana neburr yemuromo wepombi | 66 | Kuongorora kwepombi | Ita shuwa kuti pombi inopera yakatsetseka uye isina burr, uye ive nechokwadi chekuti pombi imwe neimwe yesimbi inogona kuwana "mambure maitiro epombi yakatwasuka". |

| kuongorora chigadzirwa | Ita shuwa kuti mhando ye welded pombi mumusangano inosangana nezvinodiwa | 67 | kuongorora chitarisiko | Ita shuwa kuti pamusoro pepombi yesimbi yakatsetseka, hapana kupeta, kutsemuka, kaviri ganda, lamination, lap welding uye humwe hurema huripo, bvumidza kuve nemadziro emadziro ehusina kunaka kutsauka kwakasiyana-siyana, usabvumire kuve nekukwenya kwakakomba, weld dislocation, kupisa uye vanga. |

| 68 | Internal weld kuongorora | Ita shuwa kuti welding bar yakasimba, yunifomu ukobvu, muchimiro chewaya, iyo yemukati welding bar inofanira kunge yakakwira kupfuura 0.5mm, kupinza pombi welding bar hakubvumidzwe kuve neburr. | ||

| 69 | Kuongorora kwekunze kwedhayamita | Kudzora muGB/T21835 -- 2008 yakajairwa (P5) zvinodiwa mukati mechikamu | ||

| 70 | Unroundness check | Kudzora muGB/ T3091-2015 chiyero (P4) zvinodiwa mukati meiyo renji | ||

| 71 | Kuyera kureba | Kureba kwepombi yesimbi ndeye 6m. Zvinoenderana nezvinodiwa zveGB/ T3091-2015, kutsauka kunobvumirwa kwehurefu hwese kweiyo yakatwasuka seam yakakwirira-frequency welded pombi ndeye +20mm. (pombi zvinodiwa: 4 maminetsi - 2 inches 0-5mm, 2.5 inches - 4 inches 0-10mm, 5 inches - 8 inches 0-15mm) | ||

| 72 | Bend kuona | Zvinoenderana neGB/ T3091-2015, dhigirii rekukotama rehurefu hwakazara hwepombi yesimbi haifanire kunge yakakura kupfuura 0.2% yehurefu hwepombi yesimbi. | ||

| 73 | Kuongorora kwepombi | Ita shuwa kuti musoro wepombi hauna burr uye chikamu chekupedzisira chinosangana nezvinodiwa zveGB/ T3091-2015 | ||

| 74 | Kuongorora kwekunze weld | Iyo yekunze weld scar scraping inofanirwa kushandisa arc banga, kukwesha vanga rinofanira kunge riri arc transition. | ||

| 75 | Gouges apo zvidimbu zvose zvakanga zvisipo cheki | Dzivisa kuvhura pamagumo epombi | ||

| 76 | Kuona mutswe | Dzivisa kuputika pane welding bar | ||

| 77 | Kuongorora pamwe chete | Dzivisa kubatana kwechiitiko pane welded pombi muviri | ||

| 78 | Cheka kutarisa | Dzivisa kukwenya kwakakomba pamusoro peiyo welded pombi, izvo zvinokanganisa kukora kwemadziro. Negative kutsauka kwete pasi pemadziro ukobvu (12.5%) | ||

| 79 | Gomba rekuongorora flat | Dzivirira makomba nemakomba anokonzerwa nemasimba ekunze mupombi yakasungwa. Enterprise yemukati kudzora mwero (4 maminetsi - 1 inch, gomba kudzika <2mm; 1¼ inch-2 inch, gomba rakadzika <3mm; 2½ inch-6 inches, kudzika kwegomba <4mm; 8 inches dent kudzika <6mm) | ||

| 80 | Kuongororwa kwegomba pamusoro (gomba) | Dzivisa punctate dents pamusoro pamusoro simbi chubhu | ||

| 81 | Ongorora mukati weld bar | Dzivirira iyo welding bar haina kusimba, isina kuenzana, isingasviki 0.5mm yewelding bar haina kukodzera. | ||

| 82 | Burr kuongorora | Dzivisa zvisina kujairika zvikamu zvakawandisa mukati uye kunze kwemusoro wepombi. Enterprise yemukati kudzora mwero (4 mapoinzi - 2 inches yeburr <1mm; 2½ inch kusvika 4 inch burr <2mm; 5 "- 8" burr <3mm. Ongorora: Burr haibvumidzwe pane net musoro pombi. | ||

| 83 | Kurembera muromo kutarisa | Dzivisa kuvhurika kana deformation inokonzerwa nechirauro kana kusimudza, kureva "hoisting muromo" | ||

| 84 | Kusimbisa kuputika kwekuongorora | Dzivirira kutsemuka kudiki-diki mubedhi yewelding | ||

| 85 | Kukwenya vanga risina kuenzana | Dzivisa iyo isina kuenzana welding bar mushure mekukwesha vanga. Iyo welding bar haisi yakatsetseka arc pamusoro. Musiyano wakashata wakaderera pane simbi yepasi unoonekwa seusina kuenzana | ||

| 86 | Kubva pamuromo kutarisa | Dzivirira chiitiko chewelding seam kupeta uye kumanikidzwa kunokonzerwa neyakagadzirwa zvinhu kana zvikonzero zvemuchina, iyo welding bar haina kutsetseka, kune emahara mipendero, kupeta weld dislocation, nezvimwe. | ||

| 87 | Kuongorora kweganda kaviri | Dzivisa pamusoro haisi yakatsetseka, yakaturikidzana, nyama shoma kana kusaenzana chiitiko | ||

| 88 | Scar check | Dzivisa pamusoro solder makwapa anogona kukonzera kukuvara kune base simbi | ||

| 89 | Makomba ejecha kutarisa | Dzivirira maburi pamusoro pesimbi chubhu | ||

| 90 | Oblique muromo cheki | Chikamu chemuchinjiko chepombi hachina perpendicular kumutsara wepakati, uye magumo achasangana nezvinodiwa zveGB/ T3091-2015. | ||

| 91 | Chitupa cheki | Dzivisa mucherechedzo wakanamira pane pombi muviri uye iyo chaiyo yakatarwa pombi yakashongedzwa haina kuenderana kana kusanganiswa. | ||

| mechanical test | Tarisa ma mechanical properties yezvinhu | 92 | bending test | Ongorora kunaka kwewelding yemapombi esimbi e2 inches uye pazasi kuti usangane nezvinodiwa zveGB/ T3091-2015 (P7) |

| 93 | flattening test | Kutarisa kunaka kwewelding yemapombi esimbi pamusoro pe2 inches uye kusangana nezvinodiwa zveGB/ T3091-2015 (P7) | ||

| 94 | Pressure tank test | Edza mashandiro esimbi pombi pressure groove, zvinoenderana neECCS 151-2003 trench yekubatanidza pombi engineering tekinoroji zvinodiwa (P9) | ||

| 95 | tensile test | Edza kusimba kwesimba uye kureba mushure mekutsemuka kwepombi yesimbi kuti isangane nezvinodiwa zveGB/ T3091-2015 (P7) | ||

| The water pressure test | Ongorora kusimba, kusapinda kwemhepo uye kutaridzika kwemhando yesimbi yepasi uye weld yepombi yakashongedzwa | 96 | Tarisa usati wasunungura | Dzivisa mutsauko pakati peiyo label uye iyo chaiyo yakatarwa pombi yakasungwa kana iyo yakasanganiswa batch haibvumidzwe kuburitsa (iyo imwechete batch nhamba uye yakafanana yakatarwa inotsikirirwa pamwechete. |

| 97 | kuongorora kwekuona | Kuongororwa kwechigadziko chesimbi kudzivirira kutsemuka, ganda rinorema, ngura yakakomba, maburi ejecha uye humwe hurema, zvikwambo zvakakomba hazvibvumidzwe. | ||

| 97 | Tarisa magumo usati watanga bvunzo | Pamusoro pemigumo miviri yepombi yakashongedzwa inofanira kunge yakatsetseka uye yakatsetseka kuburikidza nekutarisa kwekuona. Hazvibvumirwi kuva nemusoro wakatsetseka, kubhenda pombi uye muromo wakarembera. Chikamu chekuguma kwepombi isiri-burr inotenderera kune mutsara wepakati. Iko hakuna ndege yakarerekera uye kutsauka kunofanira kunge kuri pasi pe3 ° | ||

| 98 | Tarisa svikiro rekufambisa svikiro (mvura) usati wadzvanya | Mushure mekuzadza svikiro rekufambisa svikiro (mvura) yepombi yakashongedzwa, usamhanye kuwedzera kumanikidza. Izvo zvinodiwa kuti utarise kana iyo system ine liquid leakage | ||

| 99 | kuongorora hydrostatic | Zvinoenderana neGB/ T241-2007 yakajairwa (P2) pasi pekumanikidzwa kwekuyedzwa, kumhanyisa kumhanya uye kudzvanywa kwepakati mamiriro, yakagadzikana kwenguva yakati. Tarisa kunze kwekunze kwewelded chubhu matrix kana weld seam mukati menguva yekumanikidza kugadzikana. Hapana kubuda kana kuputika kunobvumirwa. Visally tarisa iyo yose welded pombi mushure mekuedzwa, hapana deformation yekusingaperi inobvumidzwa | ||

| 100 | Kuongororwa kwekuonekwa mushure mekuedzwa | Ita shuwa kuti hapana zvikwambo zvinotenderwa; Musoro wakatsetseka uye pombi yakakotama hazvibvumidzwe. Hapana kusvibiswa kwemafuta uye mamwe matambudziko emhando mukati nekunze kwepombi yesimbi | ||

| 101 | Chirevo chakabudiswa na | Zadza zvakanyatsoenderana neGB/ T241-2007 chiyero (P2) uye yemukati yakakosha mienzaniso (yakatumirwa katatu kudhipatimendi rekugadzira, dhipatimendi rekuongorora mhando, nesimbi pombi inonhonga imwe kopi). Hapana chitsotsi chinotenderwa | ||

| Pickling test | Deredza kukanganisa kwehutano hwehutano mune inotevera maitiro | 102 | Chitupa bvunzo | Simbisa ukobvu chaihwo hwemadziro, kutsanangurwa kana kusanganiswa kwelabel uye welded pombi nekuyera nekuyera. |

| 103 | Unroundness test | Ita shuwa kuti kusatenderedza kwepombi yesimbi kunoenderana neiyo yenyika chiyero GB/T 3091-2015 (P4) | ||

| 104 | Kuyera kureba bvunzo | Ita shuwa kuti hurefu hwepombi yesimbi inoenderana neyenyika chiyero GB/T 3091-2015 (P5) (mamita matanhatu, inotenderwa kutsauka +20mm) | ||

| 105 | Kuongorora kwekunze kwedhayamita | Ita shuwa kuti dhayamita yekunze yepombi yesimbi inosangana nezvinodiwa zveGB/T21835 -- 2008 Standard (P5) | ||

| 106 | Open test | Tarisa kana pombi inopera yakacheka chiitiko | ||

| 107 | Kuputsika bvunzo | Mushure mekuvhunduka kwesando, hapana chinoputika chiitiko pane welding bar | ||

| 108 | Kuongorora pamwe chete | Tarisa iyo imwechete chubhu pane kana pane docking phenomenon | ||

| 109 | Rusted pombi ongororo | Tarisa uone kana pane tsvina, pendi, mavara emafuta nemapombi ane ngura pamusoro pepombi yesimbi | ||

| 110 | Kuongororwa kwegomba rakadzika | Tarisa uone kana pamusoro pepombi yesimbi ine makomba emunharaunda anokonzerwa nemasimba ekunze | ||

| 111 | Kuongorora kwegomba pamusoro (makomba) | Uchishandisa ongororo yekuona, bata ruoko pamusoro pepombi yesimbi kana paine poindi yebump phenomenon. | ||

| 112 | Ongorora kana iyo yemukati welding bar inokodzera | Kudzivirira kuvapo kwemukati welding bar (kusanganisira welding yenhema) kana mukati welding bar inodarika mwero uye mamwe matambudziko; Kudzivirira iyo welding bar haina kusimba, isina kuenzana, kana isingasviki 0.5mm haina kukodzera | ||

| 113 | Burr kuongorora | Tarisa uone kana paine zvisina kujairika zvikamu zvakawandisa mukati nekunze kwechubhu kupera. Mushure mekurapwa, iyo burr yepombi kupera inofanira kunge isingasviki 0.5mm kuti ikwane | ||

| 114 | Kurembera muromo kuongorora | Kudzivirira kuvhura kana deformation yakakonzerwa muhoko nekusimudza maitiro | ||

| 115 | Kusimbisa kuputika kwekuongorora | Nekukotama kana kupepeta bvunzo, iyo welding bar yepombi yesimbi inoonekwa kudzivirira kuvepo kwekutsemuka kudiki. Tarisa kuChinyorwa 8 cheP6 cheKudzora Hunhu uye Management System yekubhenda bvunzo | ||

| 116 | Kukwenya mavanga ekuongorora | Ita shuwa kuti welding bar inokwenya vanga rakatsetseka, rakatenderera | ||

| 117 | Kuongororwa kwemahara kwechiteshi | Dzivisa chiitiko chekupeta kumanikidza pane welding seam inokonzerwa neyakagadzirwa zvinhu kana zvikonzero zvemuchina | ||

| 118 | Kuongorora kweganda kaviri | Dzivisa chiitiko chesimbi chubhu ine kaviri ganda | ||

| 119 | Denderedzwa semushenjere | Kudzivirira pamusoro pepombi yesimbi kubva kune slubby dents | ||

| 120 | Lap weld kuongorora | Kuongorora kwekuona kudzivirira chiitiko chekuwedzeredza butt welding pane simbi chubhu welding bar | ||

| 121 | Kuongororwa kwevanga | Kuongorora kwekuona kudzivirira makwapa ekushongedza pamusoro pepombi yesimbi | ||

| 122 | Makomba ejecha, kuongorora | Kuongorora kwekuona kudzivirira maburi pamusoro pepombi yesimbi | ||

| 123 | Cheka bvunzo | Tora muviri wepombi pasi pegasi rekucheka tambo zvinhu kuti uone kuti hapana kucheka kana kukuvara | ||

| 124 | Iko hakuna kunobatsira kunhonga galvanized sundries | Kuongorora kwekuona kuona kuti hapana mavara emafuta, pendi uye zvimwe zvisiri nyore kunhonga marara, kudzivirira kuvuza kweplating. | ||

| The pickling simbi pombi | Bvisa sundries senge oxide scale inogadzirwa pamusoro pesimbi pombi | 125 | Iko kusanganiswa kweasidhi | Izvo zviri mukati me hydrogen chloride mu acid concentration inofanira kudzorwa pa20% -24% |

| 126 | Underpickling kuongorora kwesimbi pombi | Kudzivirira (1) kusakwana kwekuchera nguva, kuderera kweasidhi tembiricha, kudzika kwakadzika (tembiricha inofanira kudzorwa mu25-40 ℃, acid concentration yehydrogen chloride iri 20% -24%) (2) nguva shoma yekuzunungusa yechubhu bundle (3) kuvepo kwesilicate muchoto chakasungwa simbi chubhu. | ||

| chigadzirwa kurongedza | Yakarongedzwa maererano nenhamba yakatarwa yemapombi esimbi pachidimbu | 127 | Kurongedza bhandi kuongorora | Kutakura kwepombi yesimbi kune hexagonal, 6 mabhandi ekutakura, ose akaitwa mufekitari yedu, magumo ose ebhandi rekutakura kubva kumagumo ekukanganisa kwe ± 10mm, yepakati 4 kuti igove yakakamurwa zvakaenzana, kutakura bhanhire kusungirirwa kunofanira kuenzaniswa, flat, bhandi rekutakura haritenderi kutsauka, bhanhire rekutakura rinofanira kutemwa pakusangana kwe45 ° |

| 128 | Cheki yechiratidzo | Zviri mukati ndezvechokwadi, ndege iri kumusoro, iyo yakapedzwa pombi trademark inofanirwa kunamirwa zvakanaka pane imwe neimwe pombi baffle kuti ienderane nerudyi rwekutanga welding bhandi repakati, uye kwakabva Ted embellish kunyora kwakajeka uye kwete kubvunza. |