Sida laga soo xigtay American Petroleum Institute Standard API SPEC 5CT1988 daabacaadda 1st, darajada birta ee API 5CT tuubada daasadaha saliidda waxaa loo qaybin karaa toban nooc, oo ay ku jiraan H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 iyo Q-125. Waxaan bixinaa tuubada daasadaha & API 5CT K55 Casing Tubing oo ay weheliso dunta iyo isku xidhka, ama waxaanu bixinaa alaabtayada si waafaqsan foomamka soo socda ee ikhtiyaarka ah.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

API 5CT K55 Tilmaamaha Tuubbooyinka Casing

| API 5CT K55 QAABKA TUBEESHA KAASING | ||

| OD | 10.3mm-2032mm | |

| Heerarka | API 5CT,API 5L,ASTM A53,ASTM A106 | |

| Dhererka dhererka | 3-12M ama sida looga baahan yahay macmiilka | |

| Fasalka Birta (Darajooyinka Kasarka, Dhibcaha Tuubooyinka) | Gr.A,Gr.B,Gr.C,X42,X52,X60,X65,X70 | |

| Nooca Isku-xidhka Isku-xidhka | Dhammaadka dunta aan xanaaqsanayn (NUE), dhamaadka dunta xanaaqsan ee dibadda (EUE) | |

| Takhasusyada |

| |

| Dhamaystirka Dhamaystirka | Kacsi Dibadeedku wuu dhamaanayaa (EUE), Isku-dhafka Dareemida, PH6 (iyo isku xidhka u dhigma), Wadajirka Isku-dhafka ah (IJ) | |

API 5CT K55 Kaasing Tubing Tensile & Shardiga Adag

| Kooxda | Darajo | Nooca | Wadarta dhererka culeyska saaran % | Awood soo saar MPa | Xoogga xamaasada min. MPa | Adaggu waa max. | Dhumucdiisuna waxay cayiman tahay mm | Kala duwanaanshaha qallafsanaanta la oggol yahay b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max . | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 ilaa 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 ilaa 19.04 19.05 to 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 ilaa 19.04 19.05 ilaa 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 ilaa 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aHaddi khilaaf yimaado, shaybaadhka Rockwell C baadhista adkaanta waa in loo isticmaalaa habka garsooraha. bMa jiro xad adag oo la cayimay, laakiin kala duwanaanshaha ugu badan ayaa xaddidan si waafaqsan 7.8 iyo 7.9 ee API Spec. 5CT. | ||||||||||

K55 Cabbirrada Tuubbada Casing

| Cabbirrada Dabooska Tubooyinka, Cabbirrada Dabooska Goobta Saliidda & Cabbirrada Dabooska | |

|---|---|

| Dhexroorka Duleedka | 4 1/2 "-20", (114.3-508mm) |

| Cabbirrada Casing-ka caadiga ah | 4 1/2 "-20", (114.3-508mm) |

| Nooca dunta | Duubista dunta barida, Daabka dunta wareegta dheer, Daabka dunta wareegsan ee gaaban |

| Shaqada | Waxay ilaalin kartaa tuubada tuubada. |

Dhuumaha Saliidda ee Warshadaha Shidaalka iyo Gaaska Dabiiciga ah

| Magaca Tubooyinka | Tilmaamid | Heerka Birta | Heerka | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Dhuumaha Dabooska Shidaalka | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | API Spec 5CT (8) |

| Tuubooyinka Shidaalka | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

| Isku-xidhka | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

API 5CT K55 Tilmaamaha Tubbooyinka Casing

- API 5CT K55 Casing Tubing waxaa lagu bixiyaa dhererka bilaashka ah ee u dhexeeya 8m ilaa 13m iyadoo lagu salaynayo heerka SY/T6194-96. Si kastaba ha ahaatee, sidoo kale waa la heli karaa wax aan ka yarayn dhererka 6m iyo tirada waa in aanay ka badnayn 20%.

- Qalloocyada aan kor ku soo sheegnay lama oggola inay ka soo baxaan dusha sare ee API 5CT K55 Casing Tubing coupling.

- Qallooc kasta sida timaha timaha, kala soocida, xuubka, dildilaaca ama qoloftu maaha mid la aqbali karo gudaha iyo dibadda dusha alaabta. Dhammaan cilladahan waa in gebi ahaanba meesha laga saaraa oo qoto dheer ee la saaray waa in aanay ka badnayn 12.5% dhumucda derbiga magacaaban.

- Dusha sare ee dunta isku xidhka iyo API 5CT K55 Casing Tubing waa in ay ahaataa mid siman iyada oo aan lahayn wax jeexan, jeexan ama cillado kale oo saameyn xun ku yeelan kara xoogga iyo isku xirnaanta dhow.

Waxaa muhiim u ah hawl-wadeennada saliidda iyo gaaska inay ka ilaaliyaan wax-soo-saarkooda si fiican u daxalka ilaalinta cathodic & API 5CT OilField Tubing ayaa ugu horreyn u adeegta gudbinta saliidda iyo gaaska.

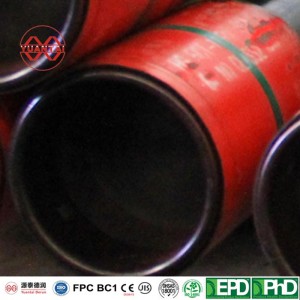

API 5CT Fasalka K55 Casing Tubing Steel Color Code

| Magaca | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | band cagaaran dhalaalaya | laba saf oo cagaar dhalaalaya | koox guduudan oo dhalaalaya | koox guduudan oo dhalaalaya + band cagaaran | koox guduudan + koox bunni ah | koox cad oo dhalaalaya |

| Isku-xidhka | isku dhafka cagaaran oo dhan + koox cad | isku xidhka cagaaran oo dhan | isku xidhka cas oo dhan | isku xidhka cas oo dhan + band cagaaran | isku dhafka cas oo dhan + koox bunni ah | isku xidhka cad oo dhan |

ISO/API dacas/ API 5CT K55 Tilmaamaha Tubbooyinka Casing

| Codea | Dia dibadda | Miisaanka magacaaban (oo leh dun iyo isku-xidhka) b,c | Dhumucda darbiga | Dhammaadka nooca habaynta | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Dhuumaha Casing Codea | API 5CT Dhuumaha dabada dhexroorka dibadda | API 5CT Tuubbada Casing Miisaanka magacaaban (oo leh dun iyo isku-xidhka) b,c | API 5CT Dhumucda gidaarka | API 5CT tuubada kasarka Dhammaadka nooca habaynta | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| Dufan wareeg gaaban oo S-Gaaban, dun wareeg ah oo dheer, dunta barafka B | ||||||||||||

| a. Koodhka waxaa loo isticmaalaa dalbashada tixraaca. | ||||||||||||

| b. Miisaanka magaca ah ee dunta dunta ah iyo daakad isku-xidhan (column 2) ayaa lagu muujiyay tixraac kaliya. | ||||||||||||

| c. Birta chromium ee Martensitic (L80 9Cr iyo 13Cr) waxay kaga duwan tahay birta kaarboon cufnaanta. Miisaanka la muujiyay ee birta chromium ee martensitic maaha qiimo sax ah. Qodobka sixitaanka ballaaran ee 0.989 waa la isticmaali karaa. | ||||||||||||

| d. C90, T95 iyo Q125 daasadda darajada birta ah waa in la keenaa iyadoo loo eegayo qeexitaanka, miisaanka iyo dhumucda gidaarka ee ku taxan shaxda sare ama nidaamka. | ||||||||||||

API 5CT K55 Halabuurka Kiimikada

| Kooxda | Darajo | Nooca | C | Mn | Mo | Cr | Waa max. | Cu max. | P max | S max | Si max | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max | min. | max | min. | max | min. | max | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 ah | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Kaarboonka L80 waxaa laga yaabaa in la kordhiyo ilaa 0.50 % ugu badnaan haddii alaabtu tahay mid saliid ah. b Maaddada molybdenum-ka ee darajada C90 Nooca 1 ma laha dulqaad ugu yar haddii dhumucda gidaarka ay ka yar tahay 17.78 mm. c Waxa ku jira kaarboon ee R95 waxa laga yaabaa in la kordhiyo ilaa 0.55 % ugu badnaan haddii sheyga saliid la demiyay. d Waxa ku jira molybdenum-ka ee T95 Nooca 1 waxa laga yaabaa in hoos loo dhigo 0.15 % ugu yaraan haddii dhumucda gidaarka ay ka yar tahay 17.78 mm. e Fasalka EW P110, ka kooban fosfooraska waa in uu ahaadaa 0.020 % ugu badnaan iyo 0.010 % ugu badnaan baaruudda. NL = xad malaha. Walxaha la muujiyo waa in lagu soo warbixiyaa falanqaynta alaabta. | |||||||||||||||

API 5CT k55 Gr. Guryaha Makaanikada

| API 5CT Casing Standard | Nooca | API 5CT Quwadda Dabacsanaanta Casing MPa | API 5CT Xoog Wax-soosaarka Kasbashada MPa | API 5CT Casing Hardness Max. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Shirkaddu waxay muhiimad gaar ah siisaa tayada badeecadaha, waxayna si aad ah u maalgelisaa soo bandhigida qalab casri ah iyo xirfadlayaal, waxayna u baxdaa dhammaan si ay u daboosho baahiyaha macaamiisha gudaha iyo dibadda.

Waxa ku jira ayaa qiyaas ahaan loo qaybin karaa: Halabuurka kiimikaad, xoogga wax-soo-saarka, xoogga adkaysiga, hantida saamaynta, iwm

Isla mar ahaantaana, shirkadu waxay sidoo kale samayn kartaa ogaanshaha cilladaha on-line iyo ka saarida iyo hababka kale ee daaweynta kulaylka iyadoo loo eegayo baahida macaamiisha.

https://www.ytdrintl.com/

iimayl:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.waa warshad tuubooyin bir ah oo ay shahaado u tahayEN/ASTM/ JISku takhasusay wax soo saarka iyo dhoofinta ee dhammaan noocyada kala duwan ee tuubo afar geesle ah, tuubada galvanized, ERW tuubada welded, tuubada wareegyada, quusin arc welded tuubada, tuubada tollayn toosan, tuubbada aan xuduud lahayn, gariiradda steel midabka dahaarka ah, gariiradda bir galvanized iyo alaabta kale ee steel.With ku habboon gaadiidka, waa 190 kiiloomitir fog ka Beijing Capital Xingang kilomitir ka Airport International Airport iyo Ti.80 km.

Whatsapp:+8613682051821