Ho ea ka American Petroleum Institute Standard API SPEC 5CT1988 1st edition, tšepe grade API 5CT oli casing pipe e ka aroloa ka mefuta e leshome, ho akarelletsa le H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 le Q-1. Re fana ka pipe ea casing & API 5CT K55 Casing Tubing e tsamaeang le khoele le coupling, kapa re fana ka sehlahisoa sa rona ho latela liforomo tse latelang bakeng sa khetho.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Litlhaloso tsa API 5CT K55 Casing Tubing

| API 5CT K55 CASING TUBING LINTLHA TSEO | ||

| OD | 10.3mm-2032mm | |

| Litekanyetso | API 5CT,API 5L,ASTM A53,ASTM A106 | |

| Length Range | 3-12M kapa ho latela tlhokahalo ea bareki | |

| Kereiti ea tšepe (Mephato ea Casing, Kereiti ea Tubing) | Gr.A,Gr.B,Gr.C,X42,X52,X60,X65,X70 | |

| Mofuta oa Screw Thread | Non upset threaded end(NUE), External upset threaded end(EUE) | |

| Tse khethehileng |

| |

| Qetella Ho Qetela | External Upset Ends (EUE), Flush Joint, PH6 (le likhokahano tse tšoanang), Integral Joint (IJ) | |

Tlhokahalo ea API 5CT K55 Casing Tubing Tensile & Hardness

| Sehlopha | Kereiti | Mofuta | Kakaretso e telele tlas'a mojaro % | Puno e matla MPa | Tensile matla min. MPa | Ho thatafala max. | Botenya ba lebota bo boletsoeng mm | Ho lumelloa ho thatafala ho fapana b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Kr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 ho 19.04 19.05 ho 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 ho 19.04 19.05 ho 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 ho 19.04 19.05 ho 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 ho 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aHa ho na le khang, tlhahlobo ea boima ba laboratori ea Rockwell C e tla sebelisoa e le mokhoa oa moahloli. bHa ho na meeli e thata e boletsoeng, empa phapang e kholo e thibetsoe ho latela 7.8 le 7.9 ea API Spec. 5CT. | ||||||||||

K55 Casing Tubing Dimensions

| Pipe Casing Sizes, Oilfield Casing Sizes & Casing Drift Sizes | |

|---|---|

| Bophara ba Kantle (Boholo ba Pipe ea Casing) | 4 1/2"-20", (114.3-508mm) |

| Mefuta e tloaelehileng ea Casing | 4 1/2"-20", (114.3-508mm) |

| Mofuta oa Khoele | Khalase ea khoele ea buttress, Khalase e telele ea khoele e chitja, Khalase e khuts'oane e chitja |

| Mosebetsi | E ka sireletsa phala ea tubing. |

Oli Tube Bakeng sa Liindasteri tsa Petroleum le Khase ea Tlhaho

| Lebitso la Liphaephe | Tlhaloso | Kereiti ea tšepe | Standard | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Pipe ea ho boloka peterole | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | API Spec 5CT (8) |

| Peterole Tubing | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

| Ho kopanya | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

API 5CT K55 Casing Tubing Features

- API 5CT K55 Casing Tubing e fanoa ka bolelele bo sa lefelloeng ho tloha ho 8m ho ea ho 13m ho latela mokhoa o tloaelehileng oa SY/T6194-96. Leha ho le joalo, e fumaneha hape ka bolelele ba 6m mme bongata ba eona ha ea lokela ho feta 20%.

- Liphetoho tse boletsoeng ka holimo ha lia lumelloa ho hlaha ka ntle ho API 5CT K55 Casing Tubing coupling.

- Phetoho leha e le efe e kang ea moriri, karohano, crease, crack kapa scab ha e amohelehe likarolong tse ka hare le ka ntle tsa sehlahisoa. Litšitiso tsena kaofela li lokela ho tlosoa ka ho feletseng 'me botebo bo tlositsoeng ha boa lokela ho feta 12.5% ea botenya ba lebota ka lebitso.

- Bokaholimo ba khoele ea ho kopanya le API 5CT K55 Casing Tubing e lokela ho ba boreleli ntle le burr, ho taboha kapa likoli tse ling tse ka bang le tšusumetso e mpe ho matla le khokahano e haufi.

Ho bohlokoa bakeng sa basebelisi ba oli le khase ho sireletsa likhase tsa bona tsa tlhahiso ho tsoa ho kutu ka tšireletso ea cathodic & API 5CT OilField Tubing e sebeletsa ho fetisetsa oli le likhase.

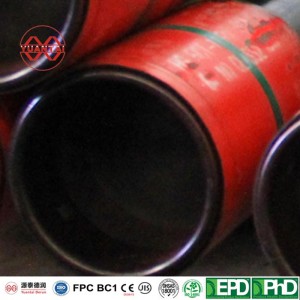

API 5CT Grade K55 Casing Tubing Steel Color Code

| Lebitso | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | sehlopha se botala bo kganyang | lihlopha tse peli tse botala bo khanyang | sehlopha se sekgubedu se kganyang | sehlopha se sefubelu se khanyang + sehlopha se setala | sehlopha se sefubelu + sehlopha se sootho | sehlopha se sesoeu se kganyang |

| Ho kopanya | ho kopanya botala kaofela + sehlopha se sesoeu | kopanelo e tala kaofela | kopanelo e kgubedu kaofela | kopano e khubelu kaofela + sehlopha se setala | kopanyo e khubelu kaofela + sehlopha se sootho | kopano e tshweu kaofela |

Litlhaloso tsa ISO/API casing/ API 5CT K55 Casing Tubing

| Codea | Dia e Ntle | Boima ba lebitso (ka khoele le coupling) b,c | Botenya ba Lerako | Qetella mofuta oa ho sebetsa | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Casing pipe Codea | API 5CT Casing pipe Bophara ba ka ntle | API 5CT Casing pipe Boima ba mabitso (ka khoele le ho kopanya) b,c | API 5CT Casing pipe Botenya ba lebota | API 5CT Casing pipe Mofuta oa ho qetela oa ho sebetsa | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Tlhalo e chitja e khuts'oane, khoele e chitja e L-Long, khoele ea B-Butress | ||||||||||||

| a. Khoutu e sebelisoa bakeng sa litšupiso tsa ho odara. | ||||||||||||

| b. Boima ba lebitso la casing e kholehileng le e kopantsoeng (khololo ea 2) e bontšoa bakeng sa litšupiso feela. | ||||||||||||

| c. Martensitic chromium steel (L80 9Cr le 13Cr) e fapane le tshepe ya carbon ka ho teteana. Boima bo bontšitsoeng ba tšepe ea martensitic chromium ha se boleng bo nepahetseng. Ntho ea khalemelo ea boima 0.989 e ka sebelisoa. | ||||||||||||

| d. Casing ea tšepe ea C90, T95 le Q125 e lokela ho fanoa ho latela litlhaloso, boima le botenya ba lebota tse thathamisitsoeng tafoleng kapa tatellano e kaholimo. | ||||||||||||

API 5CT K55 Sebopeho sa Lik'hemik'hale

| Sehlopha | Kereiti | Mofuta | C | Mn | Mo | Cr | Ke max. | Ke max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Kr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Kr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Khabone ea L80 e ka eketseha ho fihla ho 0.50 % boholo haeba sehlahisoa se tingoa ka oli. b Likahare tsa molybdenum bakeng sa Sehlopha sa 1 sa C90 ha li na mamello e fokolang haeba botenya ba lebota bo le ka tlase ho 17.78 mm. c Likahare tsa khabone bakeng sa R95 li ka eketsoa ho fihla ho 0.55 % boholo haeba sehlahisoa se tingoa ka oli. d Likahare tsa molybdenum bakeng sa T95 Mofuta oa 1 li ka fokotsoa ho isa ho 0.15 % bonyane haeba botenya ba lebota bo le ka tlase ho 17.78 mm. Bakeng sa EW Kereiti ea P110, tekanyo ea phosphorus e tla ba 0.020 % boholo le sebabole 0.010 % boholo. NL = ha ho na moeli. Lintlha tse bontšitsoeng li tla tlalehoa tlhahlobong ea lihlahisoa. | |||||||||||||||

API 5CT k55 Gr. Thepa ea Mechini

| API 5CT Casing Standard | Mofuta | API 5CT Casing Tensile Matla MPa | API 5CT Casing Yield Matla MPa | API 5CT Casing Hardness Max. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Khampani e nka bohlokoa bo boholo ho boleng ba lihlahisoa, e tsetela haholo ho kenyelletsong ha lisebelisoa tse tsoetseng pele le litsebi, 'me e tsoela pele ho finyella litlhoko tsa bareki ba hae le linaheng tse ling.

Likahare li ka aroloa ka hoo e ka bang: sebopeho sa lik'hemik'hale, matla a lihlahisoa, matla a ho tsitsa, thepa ea tšusumetso, joalo-joalo

Ka nako e ts'oanang, k'hamphani e ka boela ea etsa tlhahlobo ea bofokoli ba marang-rang le ho kenya li-anneal le mekhoa e meng ea phekolo ea mocheso ho latela litlhoko tsa bareki.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.ke feme ea phala ea tšepe e netefalitsoeng keEN/ASTM/ JISe khethehileng ka tlhahiso le ho romela thepa ea mefuta eohle ea phala lisekoere khutlonnetsepa, phala galvanized, ERW welded pipe, spiral pipe, submerged arc welded pipe, otlolohileng seam pipe, seamless pipe, color coil coil, galvanized steel coil le tse ling tsa tšepe lihlahisoa.

Whatsapp: +8613682051821