1. Papiso ea ts'ebetso ea tlhahiso

Mokhoa oa tlhahiso eaphala e otlolohileng ea tšepe ea seame batla e le bonolo. Mekhoa e ka sehloohong ea tlhahiso ke seam se otlolohileng se nang le maqhubu a phahameng-frequency weldedphala ea tšepeleka tlas'a metsi arc welded otlolohileng seam tšepe phala. Peipi ea tšepe ea seam e otlolohileng e na le ts'ebetso e phahameng ea tlhahiso, theko e tlase le nts'etsopele e potlakileng.

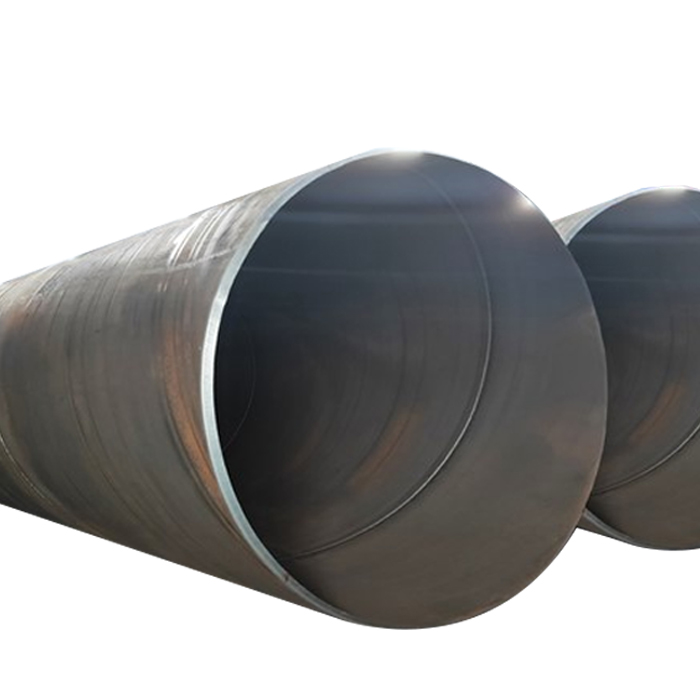

Matla aphala ea tšepe ea spiralhangata e phahame ho feta phaephe ea tšepe ea seam e otlolohileng. Mokhoa o ka sehloohong oa tlhahiso ke welding ea arc e ka tlas'a metsi. Li-tubes tsa tšepe tsa Spiral li ka hlahisa li-tubes tse cheselitsoeng tse nang le bophara bo fapaneng ba li-billet tsa bophara bo lekanang, kapali-tubes tse cheselitsoenge nang le li-diameter tse kholoanyane ho tloha ho li-billet tse moqotetsane.

Leha ho le joalo, ha ho bapisoa le liphaephe tsa tšepe tse otlolohileng tsa bolelele bo lekanang, bolelele ba welding bo eketsehile ka 30% le 100% ka ho latellana, 'me lebelo la tlhahiso le tlaase. Ka hona, liphaephe tse kholo tsa tšepe tse bophara ba tsona hangata li cheselletsoa ka li-welding tsa spiral, 'me liphaephe tse nyane tsa tšepe tse bophara ba tsona hangata li chesetsoa ka ho otloloha ha seam.

Ha o hlahisaliphaephe tsa tšepe tse nang le bophara bo boholo bo otlolohilengindastering, ho sebelisoa theknoloji ea tjheseletsa e bōpehileng joaloka T, ke hore, palo e nyenyane ea liphaephe tsa tšepe tse otlolohileng tsa seam li kopantsoe le ho kopanngoa ho kopana le bolelele bo hlokahalang ba morero. Litšitiso tsa phala ea tšepe e otlolohileng ea sebopeho sa T e tla eketseha haholo, 'me khatello e setseng ea weld e nang le sebopeho sa T e kholo. Hangata tšepe ea weld e tlas'a khatello ea triaxial, e leng ho eketsang monyetla oa ho phunyeha.

Ntle le moo, ho latela melaoana ea tekheniki ea welding ea arc e ka tlas'a metsi, weld e 'ngoe le e' ngoe e tla ba tlas'a ts'ebetso ea arc e otlang le ea ho tima arc. Leha ho le joalo, phala e 'ngoe le e' ngoe ea tšepe e ke ke ea kopana le boemo bona nakong ea ho tjheseletsa seam circumferential, kahoo ho ka 'na ha e-ba le mefokolo e eketsehileng nakong ea ho tima arc.

2. Papiso ea litekanyetso tsa ts'ebetso

Ha phala e tlas'a khatello ea ka hare, likhatello tse peli tse ka sehloohong hangata li hlahisoa leboteng la liphaephe, e leng khatello ea mahlaseli le khatello ea axial. Comprehensive stress at the weld, moo α Ke weld spiral angle ofphala ea tšepe ea spiral.

Khatello e akaretsang ho spiral weld ke khatello e kholo ea phala ea tšepe ea seam e otlolohileng. Tlas'a khatello e ts'oanang ea ts'ebetso, botenya ba lerako la liphaephe tsa tšepe tsa spiral tse nang le bophara bo lekanang ba phaephe bo nyane ho feta ba liphaephe tsa tšepe tse otlolohileng.

Nako ea poso: Jan-03-2023