YuantaiDerunlisekoere khutlonnetsepa tube na le litokelo tse fetang 63, e leng kopana le maemo a indasteri lapeng le linaheng tse ling. Sehlahisoa se fetisitse lihokelo tse fetang 200 tsa tlhahlobo ho laola boleng ba sehlahisoa.

"Ka tieo u se ke ua lumella phala ea tšepe e sa tšoaneleheng ho kena 'marakeng".

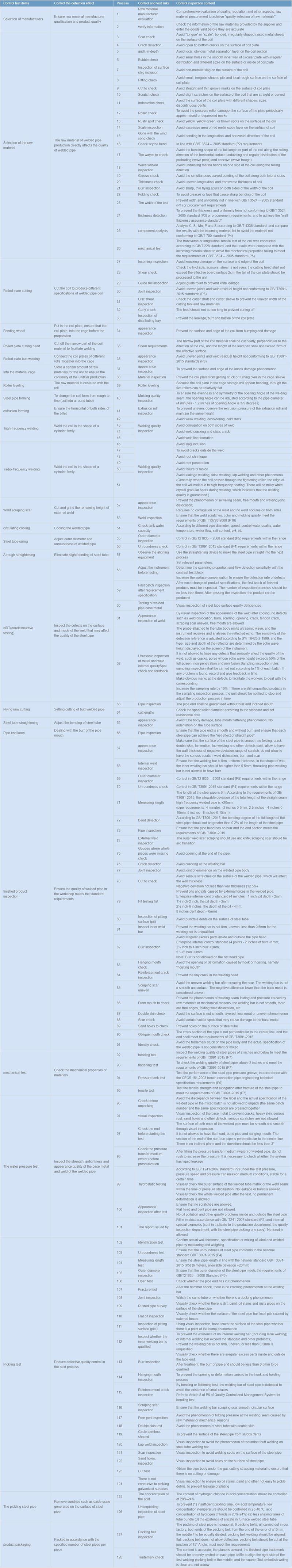

| Laola lintho tsa teko | Laola phello ea ho lemoha | Tshebetso | Lihokelo tsa taolo le liteko | Laola dikahare tsa tlhahlobo |

| Khetho ea bahlahisi | Netefatsa thuto ea moetsi oa thepa e tala le boleng ba sehlahisoa | 1 | Tlhahlobo ea moetsi oa thepa e tala | Tlhahlobo e felletseng ea boleng, botumo le likarolo tse ling, theko ea thepa e tala ho fihlela "khetho ea boleng ba lisebelisoa tse tala" |

| 2 | netefatsa litaba | Sheba lintlha tsa lisebelisoa tse tala tse fanoeng ke morekisi 'me u kenye jarete ea thepa pele li nepahetse | ||

| Khetho ea thepa e tala | Thepa e tala ea tlhahiso ea welded pipe e ama ka ho toba boleng ba phala e cheselitsoeng | 3 | Tlhahlobo ea lebala | Qoba "leleme" kapa "scale", lishiti tsa tšepe tse phahamisitsoeng ka sebopeho se sa tloaelehang holim'a khoele. |

| 4 | Ho lemoha leqheka | Qoba mapetsong a ntlha a bulehileng holim'a poleiti ea coil | ||

| 5 | hlahloba ka botebo | Qoba lesela la karohano ea tšepe ea sebakeng seo, e hlakileng karolong ea coil | ||

| 6 | Bubble hlahloba | Qoba masoba a manyane leboteng le kahare le boreleli la poleiti e chitja e nang le kabo e sa tloaelehang le boholo bo fapaneng bokaholimong kapa ka hare ho poleiti ea khoele. | ||

| 7 | Tlhahlobo ea ho kenyelletsoa ha slag holim'a metsi | Qoba slag e seng ea tšepe holim'a coil | ||

| 8 | Pitting check | Qoba mekoti e menyenyane, e sa tloaelehang le sebaka se makukuno sa sebakeng se ka holim'a coil plate | ||

| 9 | Khaola ho hlahloba | Qoba matšoao a otlolohileng le a masesaane a groove holim'a poleiti ea coil | ||

| 10 | Hlahloba | Qoba mengoako e nyane holim'a khoele e otlolohileng kapa e kobehileng | ||

| 11 | Tlhahlobo ea indentation | Qoba holim'a poleiti ea coil e nang le libopeho tse fapaneng, boholo, li-dents tse sa khaotseng | ||

| 12 | Roller hlahloba | Ho qoba tšenyo ea lirolara tsa khatello, bokaholimo ba poleiti nako le nako bo hlaha matšoao a phahamisitsoeng kapa a tepeletseng maikutlo | ||

| 13 | Ho hlahloba sebaka se mafome | Qoba matheba a mosehla, a botala bo bosehla, kapa a sootho ka holim'a khola | ||

| 14 | Tlhahlobo ea sekhahla | Qoba sebaka se feteletseng sa lera e khubelu ea tšepe holim'a coil | ||

| 15 | E tsamaile ka ho hlahloba pina ea moea | Qoba ho kobeha ka tsela ea longitudinal le e rapameng ea khoele | ||

| 16 | Sheba scythe bend | Tumellanong le litlhoko tsa GB/T 3524 -- 2005 standard (P2). | ||

| 17 | Maqhubu a ho hlahloba | Qoba sebopeho se kobehang sa bolelele bo felletseng kapa karolo ea khoele haufi le tsela e bilikang ea bokaholimo bo otlolohileng le kabo e tloaelehileng ea karolo e hlahelletseng (tlhoro ea leqhubu) le khoho (leqhubu la leqhubu) | ||

| 18 | Leqhubu la tlhahlobo ea wrinkles | Qoba ho kobeha ha marina ka lehlakoreng le leng la khoele ka tsela e bilikang | ||

| 19 | Groove hlahloba | Qoba ho kobeha ha khola ka nako e le 'ngoe ka mahlakoreng ka bobeli | ||

| 20 | Tlhahlobo ea botenya | Qoba botenya bo sa leka-lekaneng ba li-longitudinal le tse pharallang | ||

| 21 | Burr tlhahlobo | Qoba li-spurs tse bohale, tse tšesaane tse fofang mahlakoreng ka bobeli a bophara ba khoele | ||

| 22 | Ho phutha cheke | Ho qoba makukuno a bakang ho kobeha ha khoele | ||

| 23 | Bophara ba teko | Thibela bophara le ho tšoana ho sa tsamaellaneng le GB/T 3524 -- 2005 standard (P4) kapa litlhoko tsa theko | ||

| 24 | ho lemoha botenya | Ho thibela botenya le ho ts'oana ho se lumellane le GB/T 3524 -- 2005 standard (P3) kapa litlhoko tsa theko, le ho fihlela "tekanyetso ea netefatso ea botenya ba lebota" | ||

| 25 | tlhahlobo ea karolo | Sekaseka C, Si, Mn, P le S ho latela maemo a GB/T 4336, 'me u bapise liphetho le lethathamo la lisebelisoa tse kenang ho qoba thepa e sa lumellaneng le maemo a GB/T 700 (P4) | ||

| 26 | teko ea mechine | Teko e fapaneng kapa ea longitudinal tensile ea coil e entsoe ho latela maemo a GB/T 228, 'me liphetho li ile tsa bapisoa le leqephe la thepa e kenang ho qoba thepa ea mochini e sitoang ho fihlela litlhoko tsa GB/T 3524 -- 2005 standard (P5). | ||

| Ho poma poleiti | Khaola khoele ho hlahisa lintlha tse fapaneng tsa khoele ea phala e cheselitsoeng | 27 | Tlhahlobo e kenang | Qoba ho senya ts'enyo holim'a metsi le moeling oa coil |

| 28 | Cheka e kuta | Sheba lisekere tsa hydraulic, ho kuta ha ho joalo, hlooho ea ho itšeha ha ea lokela ho feta bokaholimo bo sebetsang ba 2cm, mohatla oa poleiti ea coil o lokela ho sebetsoa ho ea yuniti. | ||

| 29 | Tlhahlobo ea moqolo oa tataiso | Fetola rolara e tataisang ho thibela ho dutla ha thipa | ||

| 30 | Tlhahlobo e kopanetsoeng | Qoba manonyeletso a sa lekaneng le bophahamo ba masala a weld bo sa lumellaneng le litekanyetso tsa GB/ T3091-2015 (P8) | ||

| 31 | Tlhahlobo ea ho kuta ka disc | Lekola shaft ea cutter le sleeve ea cutter ho thibela bophara bo sa lekanang ba sesebelisoa sa ho itšeha le lisebelisoa tse tala | ||

| 32 | Curly hlahloba | Lijo ha lia lokela ho ba telele haholo ho thibela ho kobeha | ||

| 33 | Tlhahlobo ea terei ea ho aba | Thibela ho lutla, burr le buckle ea coil plate | ||

| Lebili la ho fepa | Kenya poleiti ea coil, etsa bonnete ba hore poleiti ea coil, e kene ka har'a lesaka pele ho ho lokisoa | 34 | tlhahlobo ea ponahalo | Thibela bokaholimo le ntlha ea khoele hore e se thulane le ho senyeha |

| Hlooho e sehang poleiti | Khaola karolo e moqotetsane ea lisebelisoa tsa coil ho nolofatsa welding | 35 | Litlhoko tsa ho kuta | Karolo e moqotetsane ea thepa ea li-coil e tla khaoloa ka makhethe, e pota-potile ka lehlakoreng la coil, 'me bolelele ba karolo e etellang pele ha boa lokela ho feta 2cm ea sebaka se sebetsang hantle. |

| Ho tjheseletsa butt ka poleiti | Kopanya lipoleiti tsa coil tsa meqolo e fapaneng Hammoho ka har'a lesaka | 36 | tlhahlobo ea ponahalo | Qoba manonyeletso a sa lekaneng le bophahamo ba masala a weld bo sa lumellaneng le litekanyetso tsa GB/ T3091-2015 (P8) |

| Ka har'a lesaka la lintho tse bonahalang | Boloka palo e itseng ea lisebelisoa tse tala bakeng sa yuniti ho netefatsa tsoelo-pele ea tlhahiso ea unitCar | 37 | tlhahlobo ea ponahalo | Ho thibela bokaholimo le moeli oa ts'enyo ea kokota |

| 38 | Tlhahlobo ea thepa | Thibela poleiti ea coil hore e se ke ea qaoa kapa ea fetoha ka har'a letsoho la cage | ||

| Ho leka-lekanya lirolara | Thepa e tala e tsepamisitsoe le moqolo | 39 | Ho leka-lekanya lirolara | Hobane poleiti coil ka gorole polokelo tla hlaha kobang, ka rollers tse hlano e ka ba batlang e bataletse |

| Ho etsa lipeipi tsa tšepe | Ho fetola sebopeho sa coil ho tloha ho se thata ho ea ho se setle (coil ho tube e chitja) | 40 | Tlhahlobo ea boleng ba ho bopa | Ho etsa bonnete ba hore ho lekana le ho lekana ha Angle ea ho bula ea seam welding, Angle ea ho bula e ka fetoloa ho ea ka bophara ba pipe. (Metsotso e 4 - 1.2 inches ea ho bula Angle ke likhato tse 3-5) |

| ho etsa extrusion | Netefatsa hore mahlakore ka bobeli a billet a tšekaletse | 41 | Tlhahlobo ea moqolo oa Extrusion | Ho thibela ho se lekane, hlokomela khatello ea extrusion ea roll ea extrusion mme u boloke bophahamo bo lekanang |

| tjheseletsa e phahameng ya maqhubu | Weld coil ka sebōpeho sa silindara ka tieo | 42 | Tlhahlobo ea boleng ba welding | Qoba tjheseletsa e fokolang, desoldering, batang stack |

| 43 | Qoba corrugation mahlakoreng ka bobeli a weld | |||

| 44 | Qoba ho phatloha ha weld le crack e tsitsitseng | |||

| 45 | Qoba ho theha mela ea weld | |||

| radio-frequency welding | Weld coil ka sebōpeho sa silindara ka tieo | 46 | Tlhahlobo ea boleng ba welding | Qoba ho kenyelletsa slag |

| 47 | Ho qoba mapatso ka ntle ho weld | |||

| 48 | Qoba ho honyela ha metso | |||

| 49 | Qoba ho kenella ha metso | |||

| 50 | Qoba ho hlōleha ha fusion | |||

| 51 | Qoba ho tjheseletsa ha leakage, welding ya bohata, welding lap le dintho tse ding. (Ka kakaretso, ha khoele e feta ka har'a roller e tiisang, ntlha ea khoele e tla qhibiliha ka lebaka la ho futhumala ha maqhubu a phahameng. Ho tla ba le tlhase e tšoeu ea milky crystal granular spark nakong ea welding, e bonts'ang hore boleng ba welding bo tiisitsoe.) | |||

| Weld scraping scar | Khaola 'me u sila bolelele bo setseng ba weld ea ka ntle | 52 | tlhahlobo ea ponahalo | Thibela ketsahalo ea seam swiveling, molomo o lokolohileng le ho tjheseletsa manonyeletso a dislocation; Ha e hloke corrugation ea weld 'me ha ho na li-nodule tsa weld mahlakoreng ka bobeli. |

| 53 | Tlhahlobo ea weld | Netefatsa hore mengoallo ea weld, 'mala le boleng ba ho bopa li fihlela litlhoko tsa GB/ T13793-2008 (P10) | ||

| phodiso e potolohang | Ho pholisa phala e cheselitsoeng | 54 | Lekola boholo ba metsi a tanka | Ho ea ka bophara bo fapaneng ba pipe, lebelo, taolo ea boleng ba metsi, mocheso oa metsi, phallo ea metsi, letsoai, pH, joalo-joalo |

| Sekhahla sa tube ea tšepe | Fetola bophara ba ka ntle le ho se pota-potile ha phala e cheselitsoeng | 55 | Tlhahlobo ea bophara ba kantle | Taolo ho GB/T21835 -- litlhoko tsa maemo a 2008 (P5) kahare ho sebaka |

| 56 | Tlhahlobo ea ho se pota-potile | Taolo ka litlhoko tse tloaelehileng tsa GB/ T3091-2015 (P4) ka har'a marang-rang | ||

| Ho otlolla ka thata | Tlosa ho kobeha hanyenyane ha tube ea tšepe | 57 | Ela hloko lisebelisoa tsa ho tsamaisana | Sebelisa sesebelisoa sa ho otlolla ho etsa phala ea tšepe e otlolohileng ts'ebetsong e latelang |

| NDT(teko e sa senyeheng) | Hlahloba mefokolo holim'a metsi le ka hare ho weld e ka amang boleng ba phala ea tšepe | 58 | Fetola sesebelisoa pele u etsa tlhahlobo | Beha liparamente tse amehang; Etsa qeto ea tekanyo ea ho hlahloba le ho lemoha liphoso ka boloko ea teko ea ho bapisa; Eketsa matšeliso a holim'a metsi ho netefatsa sekhahla sa ho lemoha mefokolo |

| 59 | Tlhahlobo ea pele ea sehlopha ka mor'a hore ho behoe lintlha tse ncha | Kamora phetoho e 'ngoe le e' ngoe ea litlhaloso tsa sehlahisoa, sehlopha sa pele sa lihlahisoa tse felileng se tlameha ho hlahlojoa. Palo ea makala a tlhahlobo ha ea lokela ho ba ka tlase ho tse tharo. Ka mor'a ho feta tlhahlobo, sehlahisoa se ka hlahisoa | ||

| 60 | Teko ea tšepe ea motheo ea lipeipi tse cheselitsoeng | Tlhahlobo ea pono ea mefokolo ea boleng ba boleng ba tube ea tšepe | ||

| 61 | Tlhahlobo ea ponahalo ea weld | Ka tlhahlobo ea pono ea ponahalo ea weld ka mor'a ho pholile, ha ho na likoli tse kang ho senyeha ha weld, ho chesa, ho senya, ho bula, ho phatloha, ho phatloha ha tendon, ho senya lebali le sa tšoaneng, molomo oa mahala o lumelloa. | ||

| 62 | Ultrasonic tlhahlobo ea tšepe le weld ka hare qualitySpot hlahloba le maikutlo | Probe e khomaretsoeng 'meleng oa tube e ntša leqhubu la ultrasonic,' me sesebelisoa se amohela le ho hlahloba molumo o bonahalang. Boikutlo ba sesupo sa ho lemoha bo lokisoa ho latela SY/ T6423.2-1999, 'me mofuta, boholo le botebo ba sesupo li khethoa ke bophahamo ba maqhubu a echo bo bontšitsoeng skrineng sa sesebelisoa. Ha e lumelloe ho ba le mefokolo e amang boleng ba weld ka ho teba, joalo ka mapetsong, li-pores tseo bophahamo ba maqhubu a echo bo fetang 50% ea skrineng se felletseng, ho se kenelle le ho se kopane. Melao ea tlhahlobo ea sampole: tlhahlobo ea sampole e tla etsoa ho latela 1% ea sehlopha ka seng. Haeba bothata leha e le bofe bo fumanoa, ngola 'me u fane ka maikutlo ka nako. Etsa matšoao a hlakileng ka mefokolo ho thusa basebetsi ho sebetsana le tse tsamaellanang; Eketsa sekhahla sa lisampole ka 10%. Haeba ho ntse ho na le lihlahisoa tse sa tšoaneleheng ts'ebetsong ea tlhahlobo ea sampole, yuniti e lokela ho tsebisoa ho emisa le ho lokisa ts'ebetso ea tlhahiso ka nako. | ||

| Flying saw cut | Ho seha phala ea butt-welded | 63 | Tlhahlobo ea lipeipi | Bofelo ba lipeipi bo tla tiisetsoa ntle le burr le molomo o sekametseng |

| 64 | kgaola bolelele | Sheba bophara ba rolara ea lebelo ho latela maemo a tloaelehileng mme u behe data e utloahalang | ||

| Ho otlolla tube ea tšepe | Fetola ho kobeha ha tube ea tšepe | 65 | tlhahlobo ea ponahalo | Qoba ho senyeha ha 'mele oa tube, ketsahalo ea ho bata molomo oa tube; Ha ho indentation holim'a tube |

| Pipe end boloka | Ho sebetsana le burr ea molomo oa pipe | 66 | Tlhahlobo ea lipeipi | Etsa bonnete ba hore pheletso ea pipe e boreleli ebile ha e na burr, 'me u netefatse hore pipe e' ngoe le e 'ngoe ea tšepe e ka finyella "phello ea letlooa la pipe e otlolohileng". |

| tlhahlobo ea lihlahisoa tse felileng | Etsa bonnete ba hore boleng ba phala e cheselitsoeng ka har'a workshop e kopana le litlhoko tse tloaelehileng | 67 | tlhahlobo ea ponahalo | Etsa bonnete ba hore holim'a phala ea tšepe e boreleli, ha ho na ho phutha, ho phunyeha, letlalo le habeli, lamination, lap welding le liphoso tse ling, ho lumella ho ba le botenya ba lebota la mefuta e sa tšoaneng ea ho kheloha, u se ke ua lumella ho ba le moqolo o tebileng, ho senyeha ha weld, ho chesa le lebali. |

| 68 | Tlhahlobo ea ka hare ea weld | Netefatsa hore mochini oa tjheseletsa o tiile, o botenya bo ts'oanang, ka sebopeho sa terata, mohala o ka hare oa welding o lokela ho ba holimo ho feta 0.5mm, mohala oa welding oa phala ha oa lumelloa ho ba le burr. | ||

| 69 | Tlhahlobo ea bophara ba kantle | Taolo ho GB/T21835 -- litlhoko tsa maemo a 2008 (P5) kahare ho sebaka | ||

| 70 | Tlhahlobo ea ho se pota-potile | Taolo ka litlhoko tse tloaelehileng tsa GB/ T3091-2015 (P4) ka har'a marang-rang | ||

| 71 | Ho lekanya bolelele | Bolelele ba phala ea tšepe ke 6m. Ho ea ka litlhoko tsa GB/ T3091-2015, ho kheloha ho lumelloeng ha bolelele bohle ba phala e otlolohileng ea seam high-frequency welded pipe ke +20mm. (litlhoko tsa phala: metsotso e 4 - 2 inches 0-5mm, 2.5 inches - 4 inches 0-10mm, 5 inches - 8 inches 0-15mm) | ||

| 72 | Koba ho lemoha | Ho latela GB/ T3091-2015, tekanyo e kobehang ea bolelele bo felletseng ba phala ea tšepe ha ea lokela ho ba kholo ho feta 0.2% ea bolelele ba phala ea tšepe. | ||

| 73 | Tlhahlobo ea lipeipi | Etsa bonnete ba hore hlooho ea pipe ha e na burr 'me karolo ea ho qetela e finyella litlhoko tsa GB/ T3091-2015 | ||

| 74 | Tlhahlobo ea weld ea kantle | The ka ntle weld scar scraping e lokela ho sebelisa arc thipa, scraping scaring e lokela ho ba arc transition. | ||

| 75 | Li-Gouges moo likotoana kaofela li neng li le sieo | Qoba ho bula qetellong ea phala | ||

| 76 | Ho lemoha leqheka | Qoba ho petsoha sebakeng sa welding bar | ||

| 77 | Tlhahlobo e kopanetsoeng | Qoba ketsahalo e kopanetsoeng holim'a 'mele oa phala e cheselitsoeng | ||

| 78 | Khaola ho hlahloba | Qoba likhoele tse tebileng holim'a phala e cheselitsoeng, e tla ama botenya ba lerako. Phapang e mpe eseng ka tlase ho botenya ba lebota (12.5%) | ||

| 79 | Mokoti oa teko o bataletseng | Thibela likoti le likoti tse bakoang ke matla a ka ntle ho phala e cheselitsoeng. Tekanyetso ea taolo ea kahare ea khoebo (metsotso e 4 - 1 inch, botebo ba sekoti <2mm; 1¼ inch-2 inch, botebo ba sekoti <3mm; 2½-inch-6 inches, botebo ba sekoti <4mm; botebo ba lisenthimithara tse 8 <6mm) | ||

| 80 | Tlhahlobo ea bokaholimo ba likoti (mokoti) | Qoba li-punctate dents holim'a tube ea tšepe | ||

| 81 | Hlahloba bar e ka hare ea weld | Thibela bar ea welding ha e tiile, e sa lekane, e ka tlase ho 0.5mm bakeng sa bar ea welding ha e tšoanelehe. | ||

| 82 | Burr tlhahlobo | Qoba likarolo tse sa tloaelehang tse feteletseng ka hare le ka ntle ho hlooho ea phala. Tekanyetso ea taolo ea kahare ea khoebo (lintlha tse 4 - 2 inches ea burr <1mm; 2½ inch ho isa ho 4 inch burr <2mm; 5 "- 8" burr <3mm. Tlhokomeliso: Burr ha e lumelloe phala ea hlooho ea nete. | ||

| 83 | Ho hlahloba molomo o leketlileng | Qoba ho bula kapa ho senyeha ho bakoang ke hook kapa hoisting, e leng "hoisting mouth" | ||

| 84 | Tlhahlobo ea ho matlafatsa marako | Thibela lepetso le lenyane la sefaha se tjheseletsang | ||

| 85 | Ho hohla leqeba le sa lekana | Qoba ho se leka-lekane bareng ka mor'a ho scraping lebali. The welding bar ha se sebaka se boreleli sa arc. Phapang e mpe e tlase ho feta tšepe ea motheo e nkoa e sa lekana | ||

| 86 | Ho tloha molomong ho ea hlahloba | Thibela ketsahalo ea ho phutha seam le khatello e bakoang ke lisebelisoa tse tala kapa mabaka a mochini, mochini oa welding ha o boreleli, ho na le methati ea mahala, ho phutha weld dislocation, jj. | ||

| 87 | Ho hlahloba letlalo habeli | Qoba bokaholimo ha bo boreleli, bo rarolohile, nama e fokolang kapa ntho e sa lekanyetsoang | ||

| 88 | Tlhahlobo ea lebala | Qoba matheba a holim'a solder a ka bakang tšenyo ea tšepe ea motheo | ||

| 89 | Likoti tsa lehlabathe ho hlahloba | Thibela masoba holim'a tube ea tšepe | ||

| 90 | Ho hlahloba molomo oa oblique | Karolo ea sefapano sa pipe ha e lumellane le mohala o bohareng, 'me qetello e tla finyella litlhoko tsa GB/ T3091-2015. | ||

| 91 | Tlhahlobo ea boitsebiso | Qoba letšoao la khoebo le khomaretsoeng holim'a 'mele oa phala mme litlhaloso tsa sebele tsa phala e cheselitsoeng ha li lumellane kapa li kopane. | ||

| teko ea mechine | Sheba thepa ea mochine oa thepa | 92 | teko ea ho kobeha | Lekola boleng ba tjheseletso ba liphaephe tsa tšepe tsa lisenthimithara tse peli ho ea tlase ho fihlela litlhoko tsa GB/ T3091-2015 (P7) |

| 93 | teko e bataletseng | Ho hlahloba boleng ba tjheseletsa ba liphaephe tsa tšepe ka holimo ho lisenthimithara tse peli le ho finyella litlhoko tsa GB/ T3091-2015 (P7) | ||

| 94 | Teko ea tanka ea khatello | Lekola ts'ebetso ea groove ea khatello ea lipeipi tsa tšepe, ho latela litlhoko tsa tekheniki tsa tekheniki ea CECS 151-2003 (P9) | ||

| 95 | teko ea tsitsipano | Lekola matla le bolelele ka mor'a ho robeha ha phala ea tšepe ho fihlela litlhoko tsa GB/ T3091-2015 (P7) | ||

| Teko ea khatello ea metsi | Hlahloba matla, moea le ponahalo ea boleng ba tšepe ea motheo le weld ea phala e cheselitsoeng | 96 | Hlahloba pele o phutholla | Qoba phapang pakeng tsa label le tlhaloso ea sebele ea peipi e cheselitsoeng kapa beche e tsoakiloeng ha e lumelloe ho phutholla (nomoro e tšoanang ea batch le litlhaloso tse tšoanang li hatelloa hammoho. |

| 97 | tlhahlobo ya pono | Tlhahlobo ea pono ea tšepe ea motheo ho thibela mapetsong, letlalo le boima, mafome a tebileng, masoba a lehlabathe le litšitiso tse ling, li-scratches tse tebileng ha lia lumelloa. | ||

| 97 | Sheba qetello pele u qala tlhahlobo | Bokaholimo ba lipheletsong tse peli tsa phala e cheselitsoeng e tlameha ho ba boreleli le boreleli ka tlhahlobo ea pono. Ha ea lumelloa ho ba le hlooho e bataletseng, phaephe e kobehileng le molomo o leketlileng. Karolo ea qetello ea pipe e sa burr e na le perpendicular ho ea bohareng ba mohala. Ha ho na sefofane se sekametseng mme ho kheloha ho lokela ho ba ka tlase ho 3 ° | ||

| 98 | Sheba mokhoa oa ho fetisa khatello (metsi) pele ho khatello | Ka mor'a ho tlatsa mochine o fetisang khatello (metsi) oa pipe e cheselitsoeng, u se ke ua potlakela ho eketsa khatello. Hoa hlokahala ho hlahloba hore na tsamaiso e na le ho lutla ha metsi | ||

| 99 | tlhahlobo ea hydrostatic | Ho latela maemo a GB/ T241-2007 (P2) tlas'a khatello ea teko, lebelo la khatello le maemo a mahareng a phetisetso ea khatello, a tsitsitse ka nako e itseng. Sheba bokantle bo ka ntle ba matrix a welded tube kapa seam weld nakong ea khatello ea khatello. Ha ho dutla kapa ho phatloha ho dumelletsweng. Sheba ka mahlo phala eohle e cheselitsoeng ka mor'a tlhahlobo, ha ho na deformation e sa feleng e lumelloang | ||

| 100 | Tlhahlobo ea ponahalo ka mor'a tlhahlobo | Netefatsa hore ha ho mengwapo e lumelletsoeng; Hlooho e bataletseng le pipe e kobehileng ha e lumelloe. Ha ho na tšilafalo ea oli le mathata a mang a boleng ka hare le ka ntle ho phala ea tšepe | ||

| 101 | Tlaleho e fanoeng ke | Tlatsa ka tieo ho latela maemo a GB/ T241-2007 (P2) le mehlala e khethehileng ea ka hare (e rometsoeng ka makhetlo a mararo lefapheng la tlhahiso, lefapha la tlhahlobo ea boleng, ka pipe ea tšepe e khang kopi e le 'ngoe). Ha ho boqhekanyetsi bo lumelletsoeng | ||

| Pickling teko | Fokotsa taolo ea boleng bo fosahetseng ts'ebetsong e latelang | 102 | Tlhahlobo ea boitsebiso | Netefatsa botenya ba 'nete ba lebota, sebopeho kapa ho tsoakoa ha leibole le peipi e cheselitsoeng ka ho metha le ho bekha |

| 103 | Teko ea ho se pota-potile | Etsa bonnete ba hore ho se pota-potile ha pipe ea tšepe ho lumellana le maemo a naha a GB/T 3091-2015 (P4) | ||

| 104 | Teko ea ho lekanya bolelele | Netefatsa bolelele ba phala ea tšepe ho latela maemo a naha a GB/T 3091-2015 (P5) (limithara tse 6, ho kheloha ho lumelletsoeng +20mm) | ||

| 105 | Tlhahlobo ea bophara ba kantle | Etsa bonnete ba hore bophara bo ka ntle ba phala ea tšepe bo finyella litlhoko tsa GB/T21835 -- 2008 Standard (P5) | ||

| 106 | Teko e bulehileng | Sheba hore na pheletso ea pipe e na le ts'ebetso e khaotsoeng | ||

| 107 | Teko ea ho robeha | Ka mor'a ho tsosoa ha hamore, ha ho na ts'ebetso e phunyehang sebakeng sa welding bar | ||

| 108 | Tlhahlobo e kopanetsoeng | Sheba tube e tšoanang hore na ho na le ketsahalo ea docking | ||

| 109 | Tlhahlobo ea lipeipi tse rusitseng | Sheba ka mahlo hore na ho na le litšila, pente, matheba a oli le liphaephe tse mafome holim'a phala ea tšepe | ||

| 110 | Tlhahlobo ea sekoti se bataletseng | Sheba ka mahlo hore na bokaholimo ba phala ea tšepe bo na le likoti tsa lehae tse bakoang ke matla a kantle | ||

| 111 | Tlhahlobo ea bokaholimo ba likoti (likoti) | U sebelisa tlhahlobo ea pono, tšoara letsoho holim'a phala ea tšepe hore na ho na le ntlha ea ketsahalo ea bump | ||

| 112 | Lekola hore na bar e ka hare ea welding e ea tšoaneleha | Ho thibela boteng ba ho se be le bareng tjheseletsa ka hare (ho kenyeletsoa tjheseletsa bohata) kapa ka hare tjheseletsa bar feta maemo le mathata a mang; Thibela tjheseletsa bar ha e tiile, e sa lekane, kapa e ka tlase ho 0.5mm ha e tšoanelehe | ||

| 113 | Burr tlhahlobo | Sheba ka mahlo hore na ho na le likarolo tse sa tloaelehang tse feteletseng ka hare le ka ntle ho qetellong ea tube. Ka mor'a kalafo, burr ea pheletso ea liphaephe e lokela ho ba tlase ho 0.5mm hore e tšoanelehe | ||

| 114 | Ho hlahloba molomo o leketlileng | Ho thibela ho buleha kapa ho senyeha ho bakoang ke hook le hoisting process | ||

| 115 | Tlhahlobo ea ho matlafatsa marako | Ka teko ea ho khumama kapa ho batalla, mohala oa welding oa pipe ea tšepe o fumanoa ho qoba ho ba teng ha mapetsong a manyenyane. Sheba Article 8 ea P6 ea Quality Control and Management System bakeng sa teko ea ho kobeha | ||

| 116 | Tlhahlobo ea leqeba | Netefatsa hore sebaka sa tjheseletsa se hohlang lebadi le boreledi, sedikadikwe | ||

| 117 | Tlhahlobo ea mahala ea boema-kepe | Qoba ketsahalo ea ho phutha khatello ho seam welding e bakoang ke lisebelisoa tse tala kapa mabaka a mochini | ||

| 118 | Teko ea letlalo habeli | Qoba ts'ebetso ea tube ea tšepe e nang le letlalo le habeli | ||

| 119 | Selika-likoe ka sebopeho sa bamboo | Ho thibela bokaholimo ba phala ea tšepe ho tloha ho slubby dents | ||

| 120 | Tlhahlobo ea lap weld | Tlhahlobo ea pono ho qoba ts'ebetso ea ho chesella butt e sa sebetseng holim'a tšepe ea tšepe | ||

| 121 | Tlhahlobo ea leqeba | Tlhahlobo ea pono ho qoba matheba a ho tjheseletsa holim'a phala ea tšepe | ||

| 122 | Likoti tsa lehlabathe, ho hlahloba | Tlhahlobo ea pono ho qoba masoba holim'a phala ea tšepe | ||

| 123 | Khaola teko | Fumana 'mele oa liphaephe tlas'a thepa ea ho khaola khase ho netefatsa hore ha ho na ho itšeha kapa ho senya | ||

| 124 | Ha ho na monyetla oa ho khetha li-sundries tsa galvanized | Tlhahlobo ea pono ho netefatsa hore ha ho na matheba a oli, pente le tse ling tse seng bonolo ho li khetha, ho thibela ho lutla ha plating. | ||

| Pipe ea tšepe ea pickling | Tlosa li-sundries tse kang oxide scale tse hlahisitsoeng holim'a phala ea tšepe | 125 | Khatello ea asiti | Likahare tsa hydrogen chloride ka har'a mahloriso a acid li lokela ho laoloa ho 20-24% |

| 126 | Tlhahlobo ea underpickling ea pipe ea tšepe | Ho thibela (1) nako e sa lekaneng ea pickling, mocheso o tlase oa asiti, khatello e tlase (mocheso o lokela ho laoloa ka 25-40 ℃, motsoako oa acid ea hydrogen chloride ke 20% -24%) (2) linako tse fokolang tsa ho sisinyeha ha li-tube bundle (3) ho ba teng ha silicate ka seboping se entsoeng ka tšepe. | ||

| sephutheloana sa lihlahisoa | E tletse ho latela palo e boletsoeng ea liphaephe tsa tšepe ka sengoathoana | 127 | Ho hlahloba lebanta la ho paka | Ho paka ha phala ea tšepe ho na le hexagonal, mabanta a 6 a ho paka, kaofela a etsoa fekthering ea rona, lipheletsong ka bobeli tsa lebanta la ho paka ho tloha pheletsong ea phoso ea ± 10mm, bohareng ba 4 ho aroloa ka ho lekana, tjheseletsa ea lebanta e tlamahanngoa, e bataletse, lebanta la ho paka ha le lumelle ho kheloha, lebanta la ho paka le lokela ho khaoloa, 45 ° mohokahanyi o tlameha ho khaoloa. |

| 128 | Hlahloba letšoao la khoebo | Likahare li nepahetse, sefofane se holimo, letšoao la khoebo le phethiloeng la phala le lokela ho kenngoa ka nepo holim'a phala e 'ngoe le e' ngoe ea phala ho hokahanya lehlakoreng le letona la lebanta la pele la tjheseletsa bohareng, 'me mohloli oa Ted embellish ho ngola o hlakile ebile ha o na botsitso. |