Kulingana na toleo la 1 la Taasisi ya Petroli ya Amerika ya API SPEC 5CT1988, daraja la chuma la bomba la casing la mafuta la API 5CT linaweza kugawanywa katika aina kumi, ikiwa ni pamoja na H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 na Q-1. Tunasambaza bomba la casing & API 5CT K55 Casing Tubing ikiambatana na uzi na kuunganisha, au tunatoa bidhaa zetu kwa mujibu wa fomu zifuatazo kwa chaguo.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

Vipimo vya Mirija ya API 5CT K55

| TAARIFA ZA MIFUKO YA API 5CT K55 | ||

| OD | 10.3mm-2032mm | |

| Viwango | API 5CT,API 5L,ASTM A53,ASTM A106 | |

| Msururu wa Urefu | 3-12M au kulingana na mahitaji ya mteja | |

| Daraja la Chuma (Darasa za Casing, Daraja za Tubing) | Gr.A,Gr.B,Gr.C,X42,X52,X60,X65,X70 | |

| Aina ya Uzi wa Parafujo | Ncha isiyokasirika ya mwisho(NUE), Mwisho ulio na msisitizo wa Nje(EUE) | |

| Utaalam |

| |

| Mwisho Kumaliza | Miisho ya Nje ya Kukasirika (EUE), Mchanganyiko wa Flush, PH6 (na viunganisho sawa), Pamoja Muhimu (IJ) | |

API 5CT K55 Casing Tubing Tensile & Ugumu Mahitaji

| Kikundi | Daraja | Aina | Jumla ya urefu chini ya mzigo % | Nguvu ya mavuno MPa | Nguvu ya mkazo min. MPa | Ugumu wa juu. | Unene wa ukuta ulioainishwa mm | Tofauti inayoruhusiwa ya ugumu b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max . | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Kr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Kr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 hadi 19.04 19.05 hadi 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 hadi 19.04 19.05 hadi 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 hadi 19.04 19.05 hadi 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 hadi 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aKatika kesi ya mzozo, uchunguzi wa ugumu wa maabara ya Rockwell C utatumika kama njia ya mwamuzi. bHakuna vikomo vya ugumu vilivyobainishwa, lakini tofauti ya juu zaidi imezuiwa kwa mujibu wa 7.8 na 7.9 ya API Spec. 5CT. | ||||||||||

Vipimo vya Mirija ya Casing K55

| Ukubwa wa Casing Bomba, Ukubwa wa Casing Oilfield & Ukubwa wa Casing Drift | |

|---|---|

| Kipenyo cha Nje (Ukubwa wa Bomba la Casing) | 4 1/2"-20", (114.3-508mm) |

| Ukubwa wa Casing Kawaida | 4 1/2"-20", (114.3-508mm) |

| Aina ya Thread | Mkoba wa uzi wa buttress, Uzio mrefu wa mviringo, Uzio mfupi wa duara |

| Kazi | Inaweza kulinda bomba la bomba. |

Bomba la Mafuta kwa Viwanda vya Petroli na Gesi Asilia

| Jina la Pipe | Vipimo | Daraja la chuma | Kawaida | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Bomba la Kuweka Mafuta ya Petroli | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | API Maalum 5CT (8) |

| Mirija ya Petroli | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Maalum 5CT (8) |

| Kuunganisha | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Maalum 5CT (8) |

Vipengele vya Mirija ya API 5CT K55

- API 5CT K55 Casing Tubing inatolewa kwa masafa ya bure kutoka 8m hadi 13m kwa misingi ya kawaida ya SY/T6194-96. Hata hivyo, inapatikana pia si chini ya urefu wa 6m na wingi wake haipaswi kuwa zaidi ya 20%.

- Kasoro zilizotajwa hapo juu haziruhusiwi kuonekana kwenye uso wa nje wa kiunganishi cha API 5CT K55 Casing Tubing.

- Uharibifu wowote kama vile mstari wa nywele, utengano, mpasuko, ufa au kigaga haukubaliki kwenye nyuso za ndani na nje za bidhaa. Kasoro hizi zote zinapaswa kuondolewa kabisa na kina kilichoondolewa haipaswi kuzidi 12.5% ya unene wa ukuta wa kawaida.

- Sehemu ya uzi wa kuunganisha na API 5CT K55 Casing Tubing inapaswa kuwa laini bila burr, machozi au kasoro zingine ambazo zinaweza kuwa na athari mbaya kwa nguvu na muunganisho wa karibu.

Ni muhimu kwa waendeshaji mafuta na gesi kulinda maganda ya visima vyao vya uzalishaji dhidi ya kutu kwa ulinzi wa cathodic & Tubing ya API 5CT OilField Tubing hutumika kuhamisha mafuta na gesi.

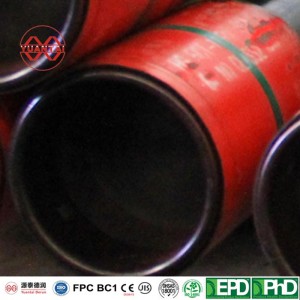

Msimbo wa Rangi wa Chuma wa API 5CT wa K55

| Jina | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | bendi ya kijani kibichi | bendi mbili za kijani kibichi | bendi ya rangi nyekundu | bendi nyekundu nyekundu + bendi ya kijani | bendi nyekundu + bendi ya kahawia | bendi nyeupe nyeupe |

| Kuunganisha | kuunganisha nzima ya kijani + bendi nyeupe | kuunganisha nzima ya kijani | muungano mzima nyekundu | kuunganisha nzima nyekundu + bendi ya kijani | kuunganisha nzima nyekundu + bendi ya kahawia | kuunganisha nyeupe nzima |

ISO/API casing/ API 5CT K55 Casing Tubing vipimo

| Codea | Dia ya Nje | Uzito wa majina (na uzi na kuunganisha) b,c | Unene wa Ukuta | Maliza aina ya usindikaji | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Casing bomba Codea | API 5CT Casing bomba Kipenyo cha nje | API 5CT Casing bomba Uzito wa jina (pamoja na thread na kuunganisha) b,c | API 5CT Casing bomba Unene wa ukuta | API 5CT Casing bomba Komesha aina ya usindikaji | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| Uzi fupi wa duara wa S-Mfupi, uzi wa mviringo wa L-Mrefu, uzi wa B-Buttress | ||||||||||||

| a. Msimbo hutumika kuagiza marejeleo. | ||||||||||||

| b. Uzito wa kawaida wa casing iliyounganishwa na iliyounganishwa (safu wima ya 2) inaonyeshwa kwa marejeleo pekee. | ||||||||||||

| c. Chuma cha chromium ya Martensitic (L80 9Cr na 13Cr) hutofautiana na msongamano wa chuma cha kaboni. Uzito ulioonyeshwa wa chuma cha chromium ya martensitic sio thamani kamili. Sababu ya kusahihisha wingi 0.989 inaweza kutumika. | ||||||||||||

| d. Kabati la daraja la chuma la C90, T95 na Q125 linapaswa kutolewa kulingana na vipimo, uzito na unene wa ukuta ulioorodheshwa kwenye jedwali au mpangilio ulio hapo juu. | ||||||||||||

API 5CT K55 Muundo wa Kemikali

| Kikundi | Daraja | Aina | C | Mn | Mo | Cr | Ni max. | Cu max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45 c | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0.43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Kr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13Kr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0.25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0.030 e | 0.030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| a Kiwango cha kaboni kwa L80 kinaweza kuongezeka hadi 0.50% kiwango cha juu ikiwa bidhaa itazimwa na mafuta. b Maudhui ya molybdenum kwa Daraja la C90 Aina ya 1 hayana uvumilivu wa chini zaidi ikiwa unene wa ukuta ni chini ya 17.78 mm. c Kiwango cha kaboni kwa R95 kinaweza kuongezeka hadi 0.55% kiwango cha juu ikiwa bidhaa itazimwa na mafuta. d Maudhui ya molybdenum kwa T95 Aina ya 1 yanaweza kupunguzwa hadi 0.15% ya chini ikiwa unene wa ukuta ni chini ya 17.78 mm. e Kwa EW Daraja la P110, maudhui ya fosforasi yatakuwa 0.020% ya juu na yaliyomo kwenye salfa 0.010% ya juu. NL = hakuna kikomo. Vipengele vilivyoonyeshwa vitaripotiwa katika uchambuzi wa bidhaa. | |||||||||||||||

API 5CT k55 Gr. Sifa za Mitambo

| API 5CT Casing Standard | Aina | API 5CT Casing Tensile Strength MPa | API 5CT Casing Yield Nguvu MPa | API 5CT Casing Ugumu Max. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | ---- |

| K55 | ≥517 | ≥655 | --- | |

| N80 | ≥689 | 552 ~ 758 | --- | |

| L80(13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | ---- |

Kampuni inatilia maanani sana ubora wa bidhaa, inawekeza sana katika kuanzishwa kwa vifaa vya hali ya juu na wataalamu, na huenda zote ili kukidhi mahitaji ya wateja nyumbani na nje ya nchi.

Yaliyomo yanaweza kugawanywa katika: muundo wa kemikali, nguvu ya mavuno, nguvu ya mkazo, sifa ya athari, nk

Wakati huo huo, kampuni pia inaweza kutekeleza ugunduzi wa dosari mtandaoni na kuziba na michakato mingine ya matibabu ya joto kulingana na mahitaji ya wateja.

https://www.ytdrintl.com/

Barua pepe :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.ni kiwanda cha mabomba ya chuma kilichothibitishwa naEN/ASTM/ JISmaalumu kwa uzalishaji na mauzo ya nje ya kila aina ya bomba mraba mstatili, bomba mabati, ERW svetsade bomba, ond bomba, iliyokuwa arc svetsade bomba, moja kwa moja mshono bomba, imefumwa bomba, coil rangi coated chuma, mabati coil na bidhaa nyingine za chuma.Pamoja na usafiri wa urahisi, ni kilomita 190 mbali na Beijing Capital Airport ya 8 kilomita kutoka Beijing.

Whatsapp:+8613682051821