Amerika Neft Instituti standarti API SPEC 5CT1988 1-nashriga ko'ra, API 5CT yog 'qog'oz quvurining po'lat navi H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 va Q-12 kabi o'nta turga bo'linishi mumkin. Biz korpus trubkasi va API 5CT K55 korpus trubasini ip va mufta bilan birga yetkazib beramiz yoki mahsulotimizni variant uchun quyidagi shakllarga muvofiq taklif qilamiz.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

API 5CT K55 korpus quvurlari texnik xususiyatlari

| API 5CT K55 KO'PLASH QUVURULARNING XUSUSIYATLARI | ||

| Mavjud o'lchamlar | 2 3/8", 2 7/8" va 3 ½" tashqi diametri | |

| Baholar | J55, J55-FBNAU, N80, L80, P110 | |

| Quvurlar | 1 1/4 “ – 2 1/16” Nom. | |

| Standartlar | API SPEC 5CT | |

| Umumiy foydalanishdagi model | 2-3/8″, 2-7/8″, 3-1/2″, 4″, 4-1/2″ | |

| Uzunlik diapazoni | R1 (6,10-7,32 m), R2 (8,53-9,75 m), R3 (11,58-12,8 m) | |

| Chelik darajasi (qopqoq navlari, quvurlar navlari) | J55, K55, N80-1, N80-Q, L80, P110 | |

| Vintli ipning turi | Buzilmagan tishli uchi (NUE), tashqi o'ralgan tishli uchi (EUE) | |

| Mutaxassisliklar |

| |

| Tugatishni tugatish | Tashqi uzilish uchlari (EUE), Flush Joint, PH6 (va ekvivalent ulanishlar), Integral birikma (IJ) | |

API 5CT K55 Korpus trubkasi valentlik va qattiqlik talabi

| Guruh | Baho | Turi | Yuklanish ostida umumiy cho'zilish % | Oqim kuchi MPa | Kuchlanish kuchi min. MPa | Qattiqlik maks. | Belgilangan devor qalinligi mm | Ruxsat etilgan qattiqlik o'zgarishi b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | maks. | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0,5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0,5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0,5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0,5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0,5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0,5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0,5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13Cr | 0,5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0,5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12,70 12,71 dan 19,04 gacha 19,05 dan 25,39 gacha ≥ 25,40 | 3,0 4,0 5,0 6,0 | |

| T95 | 1 | 0,5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12,70 12,71 dan 19,04 gacha 19,05 dan 25,39 gacha ≥ 25,40 | 3,0 4,0 5,0 6,0 | |

| C110 | - | 0,7 | 758 | 828 | 793 | 30 | 286 | ≤ 12,70 12,71 dan 19,04 gacha 19,05 dan 25,39 gacha. ≥ 25,40 | 3,0 4,0 5,0 6,0 | |

| 3 | P110 | - | 0,6 | 758 | 965 | 862 | - | - | - | - |

| 4 | 125-savol | 1 | 0,65 | 862 | 1034 | 931 | b | - | ≤ 12,70 12,71 - 19,04 ≥ 19,05 | 3,0 4,0 5,0 |

| aBahs yuzaga kelgan taqdirda, hakamlik usuli sifatida Rokvell C laboratoriya qattiqligi sinovidan foydalaniladi. bQattiqlik chegaralari ko'rsatilmagan, ammo maksimal o'zgarish API Spec 7.8 va 7.9 ga muvofiq cheklangan. 5CT. | ||||||||||

K55 Korpus quvurlari o'lchamlari

| Quvurlar korpusining o‘lchamlari, neft konining korpusining o‘lchamlari va korpusning drift o‘lchamlari | |

|---|---|

| Tashqi diametri (qopqoq quvurlari o'lchamlari) | 4 1/2″-20″, (114,3-508 mm) |

| Standart korpus o'lchamlari | 4 1/2″-20″, (114,3-508 mm) |

| Ip turi | Tayanch ipli korpus, uzun dumaloq ipli korpus, qisqa dumaloq ipli korpus |

| Funktsiya | U quvur trubasini himoya qilishi mumkin. |

Neft va tabiiy gaz sanoati uchun neft trubkasi

| Quvurlar nomi | Spetsifikatsiya | Chelik darajasi | Standart | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Neft qopqog'i quvuri | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | API Spec 5CT (8) |

| Neft quvurlari | 26,7-114,3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

| Ulanish | 127-533.4 | 12,5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

API 5CT K55 korpus quvurlari xususiyatlari

- API 5CT K55 korpus quvurlari SY/T6194-96 me'yori asosida 8 m dan 13 m gacha bo'lgan erkin uzunlik oralig'ida taklif etiladi. Shu bilan birga, u 6 m dan kam bo'lmagan uzunligi ham mavjud va uning miqdori 20% dan oshmasligi kerak.

- Yuqorida aytib o'tilgan deformatsiyalar API 5CT K55 korpus trubkasi muftasining tashqi yuzasida paydo bo'lishiga yo'l qo'yilmaydi.

- Soch chizig'i, ajralish, burma, yorilish yoki qoraqo'tir kabi har qanday deformatsiya mahsulotning ichki va tashqi yuzasida qabul qilinishi mumkin emas. Ushbu nuqsonlarning barchasi butunlay yo'q qilinishi kerak va olib tashlangan chuqurlik nominal devor qalinligining 12,5% dan oshmasligi kerak.

- Birlashma ipining yuzasi va API 5CT K55 korpus trubkasi mustahkamlik va yaqin ulanishga salbiy ta'sir ko'rsatishi mumkin bo'lgan hech qanday burma, yirtiq yoki boshqa nuqsonlarsiz silliq bo'lishi kerak.

Neft va gaz operatorlari uchun qazib olish quduqlarini korroziyadan katod himoyasi bilan himoya qilish muhim va API 5CT OilField Tubing birinchi navbatda neft va gazlarni uzatish uchun xizmat qiladi.

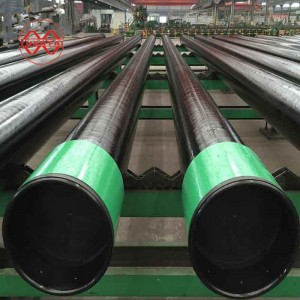

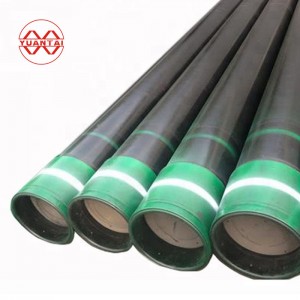

API 5CT darajasi K55 korpus quvurlari po'lat rang kodi

| Ism | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Koson | yorqin yashil tasma | ikkita yorqin yashil chiziq | yorqin qizil tasma | yorqin qizil tasma + yashil tasma | qizil tasma + jigarrang tasma | yorqin oq tasma |

| Ulanish | butun yashil birikma + oq tasma | butun yashil birikma | butun qizil birikma | butun qizil birikma + yashil tasma | butun qizil birikma + jigarrang tasma | butun oq birikma |

ISO/API korpusi/ API 5CT K55 korpus quvurlari spetsifikatsiyalari

| Codea | Tashqi dia | Nominal og'irlik (ip bilan va ulash) b, c | Devor qalinligi | Yakuniy ishlov berish turi | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177,8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177,8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177,8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177,8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177,8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177,8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177,8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72,92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Korpus quvuri Codea | API 5CT Korpus quvuri tashqi diametri | API 5CT Korpus trubkasi Nominal og'irligi (ip bilan va ulanish) b, c | API 5CT Korpus trubkasi Devor qalinligi | API 5CT Korpus trubkasi Oxirgi ishlov berish turi | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69,94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86,91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67,71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97,77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69,94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339,72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339,72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339,72 | 90,78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339,72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339,72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96,73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139,89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-qisqa dumaloq ip, L-uzun dumaloq ip, B-tugma ip | ||||||||||||

| a. Kod buyurtma ma'lumotnomasi uchun ishlatiladi. | ||||||||||||

| b. Tishli va ulangan korpusning nominal og'irligi (2-ustun) faqat ma'lumot uchun ko'rsatilgan. | ||||||||||||

| c. Martensitik xromli po'lat (L80 9Cr va 13Cr) zichligi bo'yicha karbonli po'latdan farq qiladi. Martensitik xromli po'latning ko'rsatilgan og'irligi aniq qiymat emas. Ommaviy tuzatish koeffitsienti 0,989 dan foydalanish mumkin. | ||||||||||||

| d. C90, T95 va Q125 po'latdan yasalgan korpus yuqoridagi jadval yoki tartibda ko'rsatilgan spetsifikatsiya, og'irlik va devor qalinligi bo'yicha etkazib berilishi kerak. | ||||||||||||

API 5CT K55 Kimyoviy tarkibi

| Guruh | Baho | Turi | C | Mn | Mo | Cr | Ni maks. | Cu maks. | P maks. | S maks. | Si maks. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | maks. | min. | maks. | min. | maks. | min. | maks. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - | |

| R95 | - | - | 0,45 c | - | 1.9 | - | - | - | - | - | - | 0,03 | 0,03 | 0,45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0,03 | 0,03 | - |

| L80 | 1 | - | 0,43 a | - | 1.9 | - | - | - | - | 0,25 | 0,35 | 0,03 | 0,03 | 0,45 | |

| L80 | 9Cr | - | 0,15 | 0.3 | 0,6 | 0,9 | 1.1 | 8 | 10 | 0,5 | 0,25 | 0,02 | 0,01 | 1 | |

| L80 | 13Cr | 0,15 | 0,22 | 0,25 | 1 | - | - | 12 | 14 | 0,5 | 0,25 | 0,02 | 0,01 | 1 | |

| C90 | 1 | - | 0,35 | - | 1.2 | 0,25 b | 0,85 | - | 1.5 | 0,99 | - | 0,02 | 0,01 | - | |

| T95 | 1 | - | 0,35 | - | 1.2 | 0,25 d | 0,85 | 0.4 | 1.5 | 0,99 | - | 0,02 | 0,01 | - | |

| C110 | - | - | 0,35 | - | 1.2 | 0,25 | 1 | 0.4 | 1.5 | 0,99 | - | 0,02 | 0,005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0,030 e | 0,030 e | - |

| 4 | 125-savol | 1 | - | 0,35 | 1.35 | - | 0,85 | - | 1.5 | 0,99 | - | 0,02 | 0,01 | - | |

| a L80 uchun uglerod miqdori, agar mahsulot moy bilan o'chirilgan bo'lsa, maksimal 0,50% gacha oshirilishi mumkin. b 1-toifa C90 uchun molibden miqdori devor qalinligi 17,78 mm dan kam bo'lsa, minimal bardoshlik yo'q. c R95 uchun uglerod miqdori, agar mahsulot moy bilan o'chirilgan bo'lsa, maksimal 0,55% gacha oshirilishi mumkin. d T95 1-toifa uchun molibden miqdori devor qalinligi 17,78 mm dan kam bo'lsa, minimal 0,15% gacha kamaytirilishi mumkin. e EW darajasi P110 uchun fosfor miqdori maksimal 0,020% va oltingugurt miqdori maksimal 0,010% bo'lishi kerak. NL = chegara yo'q. Ko'rsatilgan elementlar mahsulot tahlilida ko'rsatilishi kerak. | |||||||||||||||

API 5CT k55 Gr. Mexanik xususiyatlar

| API 5CT korpus standarti | Turi | API 5CT korpusning tortishish kuchi MPa | API 5CT korpusining hosildorligi MPa | API 5CT korpusning qattiqligi Maks. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | —- |

| K55 | ≥517 | ≥655 | — | |

| N80 | ≥689 | 552 ~ 758 | — | |

| L80 (13Cr) | ≥655 | 552 ~ 655 | ≤241HB | |

| P110 | ≥862 | 758 ~ 965 | —- |

Yillik ishlab chiqarishi 5 million tonna bo'lgan Yuantai Derun Xitoyda eng yirik ERW kvadrat trubkasi, to'rtburchaklar quvur, ichi bo'sh quvur, galvanizli quvur va spiral payvandlangan quvur ishlab chiqaruvchisi hisoblanadi. Yillik savdo hajmi 15 milliard dollarga yetdi. Yuantai Derunda 59 ta qora ERW quvur ishlab chiqarish liniyasi, 10 ta galvanizli quvur ishlab chiqarish liniyasi va 3 ta spiral payvandlangan quvur ishlab chiqarish liniyasi mavjud. Kvadrat quvur 20 * 20 * 1 mm dan 500 * 500 * 40MM gacha, to'rtburchaklar po'lat quvur 20 * 30 * 1,2 mm dan 400 * 600 * 40 mm gacha, spiral quvur Ø 219-1420 mm Q (s) dan 19B gacha bo'lgan po'latdan tayyorlanishi mumkin. gr.a-gr.d. Yuantai Derun ASTM A500, JIS g3466, en10219, din2240 va as1163 bo'yicha kvadrat to'rtburchaklar quvurlar ishlab chiqarishi mumkin. Yuantai Derun Xitoyda eng katta kvadrat to'rtburchaklar quvur inventariga ega bo'lib, mijozlarning to'g'ridan-to'g'ri sotib olish talabini qondira oladi.

Barchani Yuantai Derun bilan bog'lanish uchun xush kelibsiz, E-mail:sales@ytdrgg.com, va real vaqtda ulanishni tekshirish zavodi yoki zavodga tashrif buyuring!

| Mahsulot | Api 5L X42/X52/X60/X70 |

| Standart | Api 5L |

| Baho | X42, X52, X60, X65, X70 |

| Texnika | Sovuq haddelenmiş |

| OD mm | 21,3 mm 2032 mm |

| WT mm | 0,5 mm-60 mm |

| Uzunlik | 5,8m/6m/11,8m/12m yoki kerak bo'lganda |

| Yuzaki | Qora rasm / galvanizli / lak / 3LPE qoplamasi / yalang'och |

| Kelib chiqishi joyi | Xitoy (materik) |

| Ilova | 1.Suyuqlik trubkasi |

| 2. Neft quvuri | |

| 3. Gaz quvuri | |

| 4. Qozon quvurlari | |

| 5.Tuzilish quvuri | |

| 6.O'g'it trubkasi va boshqalar | |

| Qadoqlash | 8 dyuymdan pastroq quvur to'plamda bo'ladi. Yuqorida ommaviy bo'ladi. |

| Savdo shartlari | FOB, CFR, CIF, CIP va boshqalar |

| To'lov muddati | 1,30% TT avans va tekshiruvdan keyin to'langan qoldiq |

| 2.LC ko'rishda | |

| Yetkazib berish vaqti | Oldindan to'lov yoki LC olinganidan keyin 7-30 ish kuni |

FABRIK MEHMATCHILARI KO'RSATI

Ayollar erkaklardan kam emas.

Doimiy qat'iyatlilik toifadagi yagona chempionga erishdi

Vaqt hamma narsani o'zgartirishi mumkin, lekin vaqt hamma narsani o'zgartirmasligi mumkin, masalan, dastlabki yurak

Yuantay odamlari turli lavozimlarda kurashmoqda

FABRİKA SEMINAR KO'RSATI

MIJOLAR JAMOASI taqdimoti

Etkazib berish va logistika

Kompaniya mahsulot sifatiga katta ahamiyat beradi, ilg'or uskunalar va mutaxassislarni joriy etishga katta miqdorda sarmoya kiritadi va mijozlarning ichki va xorijdagi ehtiyojlarini qondirish uchun barcha imkoniyatlarni ishga soladi.

Tarkibni taxminan quyidagilarga bo'lish mumkin: kimyoviy tarkibi, oqish kuchi, valentlik kuchi, zarba xususiyati va boshqalar.

Shu bilan birga, kompaniya mijozlar ehtiyojlariga ko'ra on-layn nuqsonlarni aniqlash va tavlanish va boshqa issiqlik bilan ishlov berish jarayonlarini ham amalga oshirishi mumkin.

https://www.ytdrintl.com/

E-mail:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.tomonidan sertifikatlangan po'lat quvur zavodi hisoblanadiEN/ASTM/ JISBarcha turdagi kvadrat to'rtburchaklar quvur, galvanizli quvur, ERW payvandlangan quvur, spiral trubka, suv osti payvandlangan quvur, tekis tikuv trubkasi, choksiz quvur, rangli qoplangan po'lat rulo, galvanizli po'lat rulo va boshqa po'latdan yasalgan mahsulotlarni ishlab chiqarish va eksport qilishga ixtisoslashgan. Xingang.

Whatsapp: +8613682051821

Bizga xabaringizni yuboring:

-

YOG'LI po'lat quvur ULTIMIL SOTISH

-

Yuqori korroziyadan himoyalangan issiq haddelenmiş qora uglerodli payvandlangan po'lat dumaloq quvur

-

API 5CT SMLS korpusi K55-N80

-

API 5L SMLS liniyasi quvuri X42-X70

-

Issiq sotiladigan ASTM A53 A106 API 5L Payvandlangan quvur

-

Smls po'lat quvur liniyasi Api 5L X42/X46/X60/X70