Malunga nemveliso

Singakuthumelela iinkcukacha ezithe rhoqo ngenkonzo ye-LCL.

Ukupeyinta i-oyile echasene nokugqwala,

ukupeyinta ivanishi,

ipeyintiwe i-ral3000,

yenziwe igalati,

3LPE, 3PP

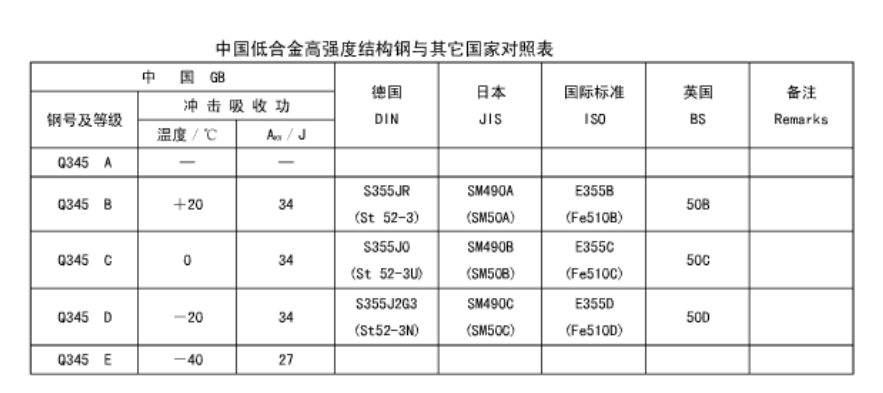

Q195 = S195 / A53 iBanga A

Q235 = S235 / A53 iBanga B / A500 iBanga A / STK400 / SS400 / ST42.2

Q345 = S355JR / A500 iBanga B iBanga C

Q235 Al wabulawa = EN39 S235GT

L245 = Api 5L / ASTM A106 iBanga B

Umbhobho omnyama ngumbhobho wentsimbi ongenanto ngaphandle kweengubo zokukhusela. Umbhobho omnyama usetyenziselwa iintlobo ezahlukeneyo zezicelo ezijikeleze ikhaya. Kuqheleke kakhulu ukubona umbhobho omnyama usetyenziselwa umgca wakho wegesi yendalo kunye nemigca yenkqubo yokutshiza. Ekubeni umbhobho omnyama awunayo into yokukhusela, unokugqwala ngokulula kwindawo emanzi okanye efumileyo. Ukumisa umbhobho ekugqumeni okanye ukubola ngaphandle, kufuneka unikeze umaleko wokukhusela ngaphandle kombhobho. Eyona ndlela ilula kukupeyinta.

EWE. Sinentsebenziswano enamandla kunye ne-SINOSURE

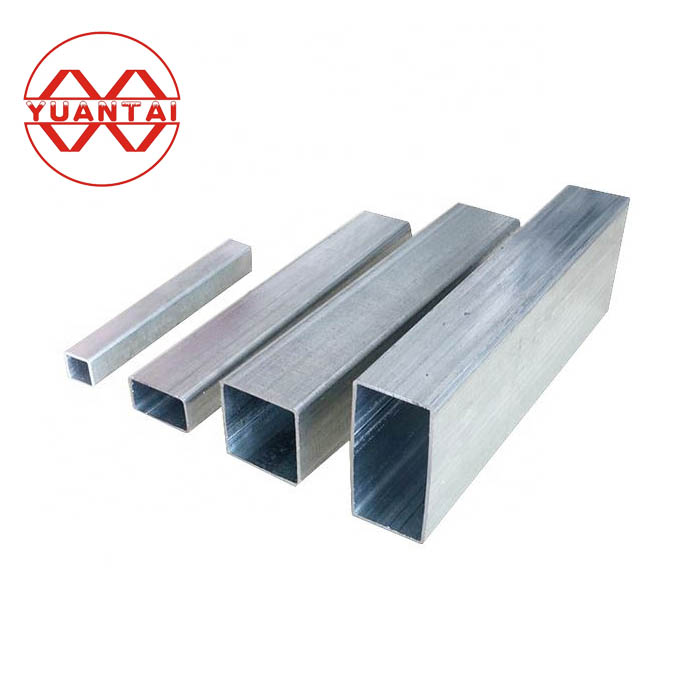

I-RHS imele iRectangular Hollow Section, engumbhobho wentsimbi oxande.

Sikwanayo nenxalenye yesikwere umngxuma umbhobho yentsimbi, ngokwemigangatho: ASTM A500, EN10219, JIS G3466, GB/T6728 ebandayo eyenziwe isikwere kunye umbhobho yentsimbi rectangular.

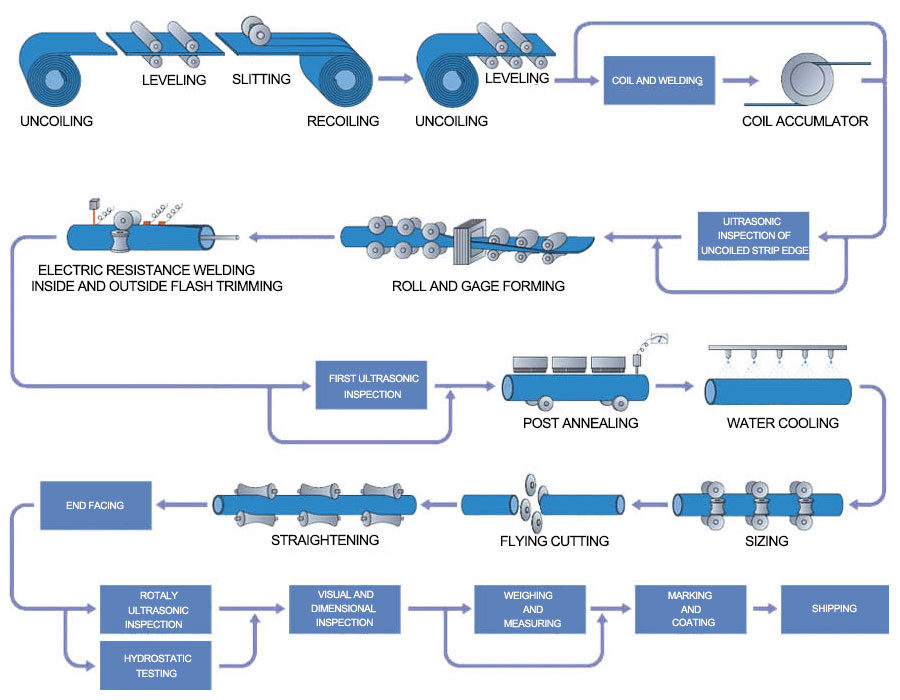

ERW umbhobho wentsimbi, umbhobho wentsimbi ye-SSAW, umbhobho wentsimbi we-LSAW, umbhobho wentsimbi, umbhobho wentsimbi, umbhobho wentsimbi, umbhobho wentsimbi, ingqiniba, isinciphisi, i-cap, ukudibanisa, i-flange, i-weldolet, umbhobho wentsimbi ongenamthungo.

TT, L / C (Ngomyalelo omkhulu, iintsuku ezingama-30-90 zingamkeleka).

Imibhobho yentsimbi eyakhiwe ngesinyithi yahlulwe yaba yimibhobho yentsimbi epholileyo ediphu kunye nemibhobho yentsimbi ediphu eshushu. Imibhobho eyenziwe ngegalati idla ngokusetyenziselwa amanzi, irhasi, i-oyile kunye neminye imibhobho yoxinzelelo oluphezulu oluqhelekileyo. Zikwasetyenziswa kwishishini le-kerosene, ngakumbi imibhobho ye-oyile kwindawo yeoyile engaselunxwemeni, iicoolers, imibhobho yokutshintshiselana ngomphunga wamalahle kunye neengqumba zemibhobho yebhulorho, imibhobho yokuxhasa umgodi, njl.

Imibhobho yentsimbi eyakhiwe ngesinyithi yahlulwe yaba yimibhobho yentsimbi epholileyo ediphu kunye nemibhobho yentsimbi ediphu eshushu. Imibhobho eyenziwe ngegalati idla ngokusetyenziselwa amanzi, irhasi, i-oyile kunye neminye imibhobho yoxinzelelo oluphezulu oluqhelekileyo. Zikwasetyenziswa kwishishini le-kerosene, ngakumbi imibhobho ye-oyile kwindawo yeoyile engaselunxwemeni, iicoolers, imibhobho yokutshintshiselana ngomphunga wamalahle kunye neengqumba zemibhobho yebhulorho, imibhobho yokuxhasa umgodi, njl.

Kuthiwa umbhobho wensimbi owenziwe ngentsimbi usetyenziselwa igesi kunye nokufudumeza. Njengombhobho wamanzi, inani elincinci lomhlwa liya kufumaneka emva kweminyaka embalwa. Ayingcolisi kuphela izinto zococeko, kodwa neebhaktheriya zikhula kudonga lwangaphakathi lombhobho. Umhlwa ubangela isiqulatho sesinyithi esiphakamileyo kumzimba wamanzi kwaye ibeka emngciphekweni impilo yabantu.

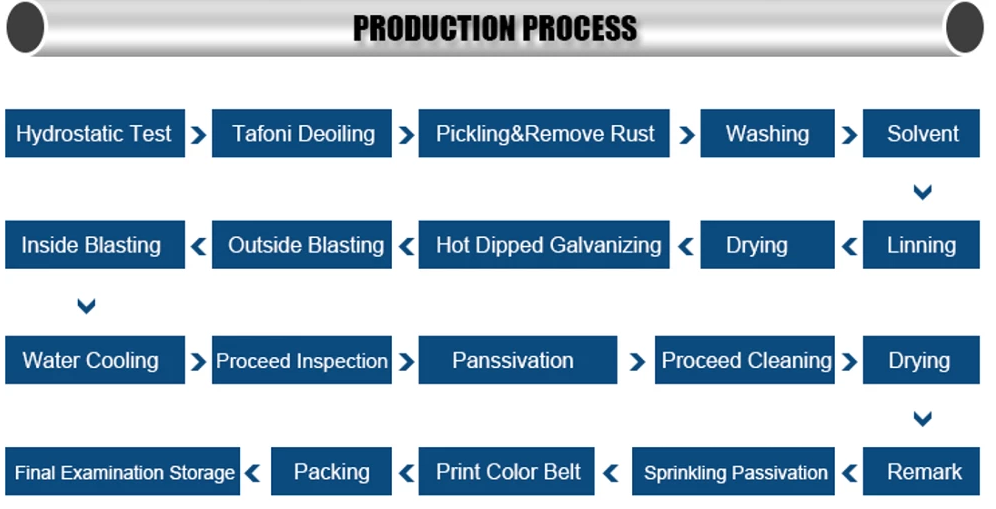

I-Hot dip galvanizing kukuntywilisela umbhobho wentsimbi kwi-asidi yokuhlamba, kwaye ulungiselele isisombululo se-aqueous nge-ammonium chloride isisombululo se-aqueous okanye i-zinc chloride kunye ne-zinc chloride, kwaye ugalele kwi-groove. Idiphu eshushu yokwambathisa iyunifomu, incamathele ngamandla kunye nobomi benkonzo ende. I-matrix ye-hot-dip galvanized steel pipe sisisombululo esinzima somzimba kunye nesinyibilikisiweyo se-electroplating, ngoko ke ukusabela kweekhemikhali kuhlanganisa ukubunjwa kwe-compact kunye nokuxhathisa ukubola. Uluhlu lwe-alloy luxutywe kunye ne-zinc ecocekileyo kunye nesiseko sombhobho wensimbi, ngoko unokumelana nokuqina kwe-corrosion.

Umbhobho obandayo owenziwe yizinki ufakwe i-electro galvanized, kwaye kukho umahluko omkhulu phakathi kokumelana nomhlwa kunye nombhobho owenziwe yizinki oshushu. Ukuze kuqinisekiswe umgangatho, uninzi lwabavelisi bolawulo lwe-galvanizing olusesikweni alusebenzisi i-electro galvanizing (i-cold plating). Loo mashishini amancinci angekho sikweni aya kusebenzisa i-electro galvanizing kuba ixabiso liphantsi kakhulu. Umaleko owenziwe ngegalvanized wombhobho wentsimbi opholileyo wediphu yingubo yokwaleka. Uluhlu lwe-zinc lufakwe ngokuzimeleyo kunye ne-matrix yombhobho wensimbi. Uluhlu lwe-zinc luncinci, oludibaniswa nje kumbhobho wensimbi kwaye kulula ukuwa. Ke ngoko, ukuxhathisa kwayo kukonakala. Ke ngoko, kweminye imibhobho engcwatywe ngokuthe ngqo, imibhobho yentsimbi eyenziwe ngamazinki eyenziwe ngabavelisi besiqhelo isasetyenziswa.

Uwususa njani umbhobho wentsimbi onomhlwa?

Okokuqala, sebenzisa i-solvent ngaphandle kwentsimbi ukuze ususe i-organic matter. Umhlwa unokususwa ngokukhethwa emva kokuxubha ukuthintela umhlwa, ukucoca okanye intsimbi, umhlwa, i-welding slag, njl. Ukugquma kwe-thermoelectric akukho lula ukugqwala kwaye ukugquma okubandayo kulula ukugqwala.

Umbhobho wangoku wokunikezelwa kwamanzi omlilo ngoku ngokusisiseko usebenzisa umbhobho we-galvanized, kwaye umaleko wangaphandle wombhobho we-galvanized usetyenziswa kuluhlu lwepeyinti. Ingabonwa ukuba umbhobho womlilo ngokwenene ufakwe i-galvanized. Kwisakhiwo sensimbi, ubunjineli be-welding inenxaxheba yayo. Ngoko ke, ukusetyenziswa rhoqo kombhobho wensimbi yensimbi kunokuthintela ukuvela kweemeko zokugqwala ixesha elide.

1. OD 219mm nangaphantsi Kwimiyanda engama-hexagonal ekulungele ulwandle epakishwe ngemicu yentsimbi, Nezilingi ezimbini zenayiloni kwimiqulu nganye

2. ngaphezulu kwe-OD 219mm ngobuninzi okanye ngokwembono yesiko

3. Iitoni ezingama-25/isikhongozeli kunye neetoni ezi-5/ubungakanani bomyalelo wokulinga;

4. Kwi-container eyi-20" ubukhulu bobude yi-5.8m;

5. Kwi-container eyi-40" ubukhulu bobude yi-11.8m.

EWE SINAYE

YUANTAIDERUN Brand TOP 500 China

Umxube osekelwe kwisinyithi uthathwa njengentsimbi ye-alloy xa i-manganese inkulu kune-1.65%, i-silicon ngaphezu kwe-0.5%, i-copper ngaphezu kwe-0.6%, okanye ezinye izinto ezincinci ze-alloying ezifana ne-chromium, i-nickel, i-molybdenum, okanye i-tungsten ikhona. Iintlobo ezininzi zeepropathi ezihlukeneyo zinokudalwa kwintsimbi ngokufaka ezi zinto kwiresiphi.

Inkqubo yokuphucula ngakumbi insimbi engenasici ngokunciphisa umxholo wekhabhoni

Ubungakanani bekhabhoni kwinsimbi engenasici kufuneka ibe ngaphantsi kwe-carbon steel okanye i-alloy iron ephantsi (oko kukuthi, intsimbi enomxholo we-alloying element ngaphantsi kwe-5%). Nangona i-electric arc furnaces (EAF) iyindlela eqhelekileyo yokunyibilika kunye nokucoca insimbi engenasici, i-AOD yongezelela ukonga, njengoko ixesha lokusebenza lifutshane kwaye amaqondo okushisa aphantsi kune-EAF steelmaking. Ukongeza, ukusebenzisa i-AOD yokusulungekisa insimbi engenasici kwandisa ukufumaneka kwe-EAF ngeenjongo zokunyibilika.

Intsimbi enyibilikisiweyo, engacocwanga idluliselwa kwi-EAF ibe yinqanawa eyahlukileyo. Umxube we-argon kunye ne-oxygen uvuthelwa ukusuka ezantsi kwenqanawa ngentsimbi enyibilikisiweyo. Ii-agent zokucoca zongezwa kwisitya kunye nezi gesi zokuphelisa ukungcola, ngelixa i-oksijini idibanisa nekhabhoni kwintsimbi engabonakaliyo ukunciphisa izinga lekhabhoni. Ubukho be-argon buphucula ubudlelwane bekhabhoni yeoksijini kwaye ngaloo ndlela buququzelela ukususwa kwekhabhoni.

I-corrosion ye-structural steel yinkqubo ye-electrochemical efuna ubukho bexesha elifanayo lokufuma kunye ne-oxygen. Xa kungekho nanye, umhlwa awenzeki. Ngokusisiseko, isinyithi kwintsimbi i-oxidised ukuvelisa i-rust, ehlala malunga namaxesha angama-6 umthamo wezinto zokuqala ezisetyenzisiweyo kwinkqubo. Inkqubo yomhlwa ngokubanzi ibonisiwe apha.Kunye nomhlwa ngokubanzi, kukho iintlobo ngeentlobo zomhlwa onokuthi zenzeke; i-bimetallic corrosion, i-corrosion ye-pitting kunye ne-crevice corrosion. Nangona kunjalo, ezi zithande ukuba zingabalulekanga kulwakhiwo lwentsimbi. Umyinge oqhubela ngawo umhlwa uxhomekeke kwinani leemeko ezinxulumene 'nemozulu encinci' ejikeleze ubume besakhiwo, ingakumbi ixesha lokumanzi kunye nenqanaba longcoliseko lomoya. Ngenxa yeeyantlukwano kwimo engqongileyo ye-atmospheri, idatha yezinga lokubola ayinakwenziwa ngokubanzi. Nangona kunjalo, iindawo ezisingqongileyo zinokuhlelwa ngokubanzi, kwaye imilinganiselo yokuthotywa kwentsimbi elinganisiweyo inika isalathiso esiluncedo samazinga okuhlwa anokubakho. Ulwazi oluninzi lunokufumaneka kwi-BS EN ISO 12944-2 kunye ne-BS EN ISO 9223

IpeyintiweI-SHS (amacandelo anomngxuma osisikwere)kunye ne-RHS (i-rectangular hollow sections) ziintsika eziphakamileyo ezibandayo ezenziwe ngentsimbi epholileyo ezipeyintiweyo zokukhusela ngexesha lokugcinwa kunye nokuphathwa.

Isiphumo somfanekiso weHot dip umbhobho wentsimbi owenziwe ngamagalvanized square

Kwixesha elide, ukubonakaliswa okuqhubekayo, ubushushu obuphezulu obucetyiswayo kwintsimbi eshushu yokudipha yi-200 °C (392 °F), ngokutsho kwe-American Galvanizers Association. Ukusetyenziswa kwentsimbi yegalvanized kumaqondo obushushu angaphezulu koku kuya kubangela ukuxobulwa kwe-zinc kwi-inter metallic layer.

Lithetha icandelo elisisikwere elihollow elishunqulelwe njenge-SHS

Lithetha icandelo elijikelezayo elinomngxuma, elishunqulelwe njenge-SHS.

Malunga nokuhanjiswa

Ngokubanzi ziintsuku ezi-3-5 ukuba iimpahla zikhoyo. okanye malunga neentsuku ezingama-25 ukuba iimpahla azikho kwisitokhwe kwaye oko kuhambelana nemfuno yeodolo.

Ukuya eMzantsi Afrika: iintsuku ezingama-45

Ukuya kuMbindi Mpuma: iintsuku ezingama-30

Ukuya kuMzantsi Merika: iintsuku ezingama-60

Ukuya kuMntla Merika: iintsuku ezingama-30

Ukuya eRashiya: iintsuku ezisi-7

Ukuya eYurophu: iintsuku ezingama-45

Ukuya eMzantsi Korea: iintsuku ezi-5

Ukuya eJapan: iintsuku ezi-5

Ukuya eVietnam: iintsuku ezili-15

Ukuya eThailand: iintsuku ezili-15

Ukuya eIndiya: iintsuku ezingama-30

Ukuya eIndonesia: iintsuku ezili-15

Ukuya eSingapore: iintsuku ezili-10

Malunga nenkonzo

I-YUANTAIDERUN UMGANGATHO OLUNGILEYO IXABISO INKONZO ELUNGILEYO.

Sinebhubhoratri yobungcali,

Nabasebenzi bovavanyo abaqeqeshiweyo.

Amabango oMgangatho/uMyinge: Umthengi unelungelo lokwenza ibango lomgangatho kunye nobungakanani ngokubhaliweyo ngokuchasene noMthengisi kwiintsuku ezingama-90 emva kokufika kwizibuko lendawo.

EN210 EN219 BC1 API UL ISO FPC CE EPD PHD JIS3466 GB

A: 1.Sigcina umgangatho omhle kunye nexabiso elikhuphisanayo ukuze siqinisekise inzuzo yabathengi bethu.

2.Sihlonipha wonke umthengi njengomhlobo wethu kwaye senza ishishini ngokunyanisekileyo kwaye senze ubuhlobo nabo, kungakhathaliseki ukuba bavela phi.

Ewe, ungafumana iisampulu ezifumanekayo kwisitokhwe sethu.Sisimahla kwiisampulu zokwenyani, kodwa abathengi kufuneka bahlawule iindleko zothutho.

Amathuba okusebenzisa intsimbi kwizakhiwo kunye neziseko zophuhliso azinamda. Ezona zicelo zixhaphakileyo zidweliswe ngezantsi.Kwizakhiwo Amacandelo esakhiwo: ezi zibonelela ngesakhelo esomeleleyo, esomeleleyo kwisakhiwo kwaye zenza i-25% yokusetyenziswa kwentsimbi kwizakhiwo.Imivalo yokuqinisa: ezi zongeza amandla okuqina kunye nokuqina kwikhonkrithi kwaye zenza i-44% yokusetyenziswa kwentsimbi kwizakhiwo. Intsimbi isetyenziswa kuba ibophelela kakuhle kwikhonkrithi, inomlinganiselo ofanayo wokwandisa i-thermal kwaye yomelele kwaye ingabizi kakhulu. Ikhonkrithi eyomeleziweyo ikwasetyenziselwa ukubonelela ngeziseko ezinzulu kunye namagumbi angaphantsi kwaye okwangoku isesona siseko siphambili sokwakha emhlabeni. Iimveliso zeshiti: i-31% ikwimveliso yephepha efana nophahla, i-purlins, iindonga zangaphakathi, iisilingi, i-cladding, kunye neepaneli zokukhusela ngaphandle kweendonga. iileyili, iishelufa kunye nezinyuko nazo zenziwe ngentsimbi. Kwiziseko ezingundoqo Uthungelwano lwezothutho: intsimbi iyafuneka kwiibhulorho, itonela, isiporo sikaloliwe nasekwakheni izakhiwo ezifana nezikhululo zamafutha, izikhululo zikaloliwe, amazibuko nezikhululo zeenqwelomoya. Malunga ne-60% yokusetyenziswa kwentsimbi kwesi sicelo injenge-rebar kwaye intsalela ngamacandelo, iipleyiti kunye nomzila kaloliwe.Izinto ezisetyenziswayo (amafutha, amanzi, amandla): ngaphezu kwe-50% yentsimbi esetyenzisiweyo kwesi sicelo ikwimibhobho engaphantsi komhlaba yokuhambisa amanzi ukuya nokubuya kwizindlu, kunye nokuhambisa igesi. Eminye iyindawo yerebar yezikhululo zombane kunye nezindlu zokumpompa.