Di-omestic petroleum, iikhemikhali kunye namanye amashishini amandla adinga inani elikhulu lentsimbi yobushushu obuphantsi ukuyila nokuvelisa izixhobo ezahlukeneyo zokuvelisa nokugcina ezifana negesi yepetroleum engamanzi, i-ammonia elulwelo, ioksijini engamanzi kunye nenitrogen engamanzi.

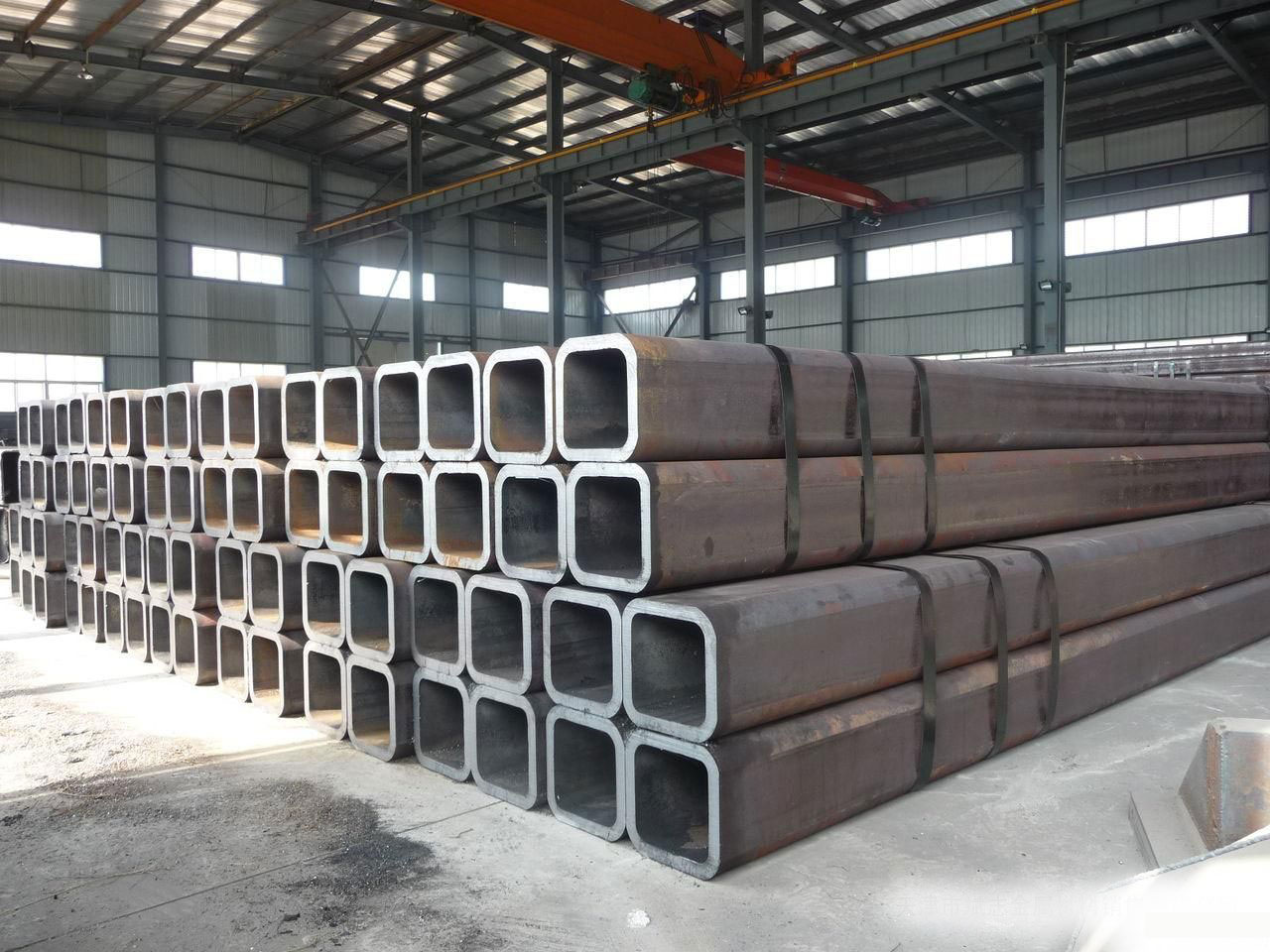

NgokweSicwangciso seMinyaka emiHlanu ye-12 yaseTshayina, uphuhliso lwamandla epetrochemical luya kuphuculwa kwaye uphuhliso lwemithombo ye-oyile negesi luya kukhawuleziswa kule minyaka mihlanu izayo. Oku kuya kubonelela ngemarike ebanzi kunye nethuba lophuhliso lokuvelisa amandla kunye nemveliso yezixhobo zokugcina phantsi kweemeko zenkonzo yobushushu obuphantsi, kwaye kuya kukhuthaza uphuhlisoQ355D ubushushu obuphantsi obuxhathisa ityhubhu yoxandeizixhobo. Njengoko imibhobho yobushushu obuphantsi ifuna ukuba iimveliso zingabi namandla aphezulu kuphela kodwa kunye nobunzima obuphezulu kunye nobushushu obuphantsi, imibhobho yobushushu obuphantsi ifuna ukucoceka okuphezulu kwentsimbi, kunye nomlinganiselo wendandatho yobushushu, ukucoceka kwentsimbi nako kuphezulu. Q355Eityhubhu yesikwere sobushushu obuphantsi kakhuluiyaphuhliswa kwaye iyilwe. Intsimbi ye-billet ingasetyenziswa ngokuthe ngqo njengombhobho wensimbi ongenamthungo wokuThumela isakhiwo. Inkqubo yokuvelisa ibandakanya ezi ngongoma zintathu zilandelayo:

(1)Ukunyibilikiswa kwesithando sombane se-arc: isinyithi esilahliweyo kunye nentsimbi yehagu zisetyenziswa njengeiimpahla ezingekasilwa, phakathi kwazo i-scrap steel akhawunti ye-60-40% kunye ne-pig iron account ye-30-40%. Ukuthatha inzuzo ye-alkalinity ephezulu, ubushushu obuphantsi kunye ne-iron oxide ephezulu yesithando sombane sombane we-arc ephezulu, ukushukunyiswa okukhulu kwe-oksijini decarburization ngumpu weoksijini eludongeni lwesithando somlilo, kunye nokunyibilikisa amanzi okuqala okwenza intsimbi kunye ne-impedance ephezulu kunye ne-ultra-high-high, i-nitrogen ye-furnace yamandla, i-hydrogen grade eyingozi, i-nitrogen ye-furnace kunye nezinto ezinobungozi. i-non-metallic inclusions kwintsimbi etyhidiweyo inokususwa ngempumelelo. Isiphelo sekhabhoni yentsimbi etyhidiweyo kwisithando sombane se-arc <0.02%, i-phosphorus <0.002%; I-deoxidation enzulu yensimbi etyhidiweyo iqhutyelwa kwinkqubo yokucima isithando sombane, kunye nebhola ye-A1 kunye ne-carbasil yongezwa ukwenza i-deoxidation yangaphambili.

Umxholo we-aluminium kwintsimbi etyhidiweyo ilawulwa kwi-0.09 ~ 1.4%, ukwenzela ukuba i-Al203 inclusions eyenziwe kwintsimbi yokuqala etyhidiweyo inexesha elaneleyo lokudada, ngelixa umxholo we-aluminium we-tube billet steel emva kokucocwa kwe-LF, unyango lwe-vacuum ye-VD kunye nokudibanisa okuqhubekayo kufikelela kwi-0.020 ~ 0. oxidation kwinkqubo yokucokisa iLF. I-nickel plate accounting ye-25 ~ 30% ye-alloy iyonke yongezwa kwi-ladle ye-alloying; Kwimeko apho umxholo wekhabhoni ungaphezulu kwe-0.02%, umxholo wekhabhoni wensimbi ye-ultra-low-low ayikwazi ukuhlangabezana nemfuno ye-0.05 ~ 0.08%. Nangona kunjalo, ukuze kuncitshiswe i-oxidation yensimbi etyhidiweyo, kuyimfuneko ukulawula ukunyanzeliswa kwe-oksijini yokuvuthela kwe-oxygen eludongeni lwe-oxygen gun ukulawula umxholo wekhabhoni yensimbi etyhidiweyo ngaphantsi kwe-0.02%; Xa umxholo we-phosphorus ulingana ne-0.002%, umxholo we-phosphorus wemveliso uya kufikelela ngaphezu kwe-0.006%, eya kwandisa umxholo we-phosphorus into eyingozi kwaye ichaphazele ukuqina kobushushu obuphantsi bentsimbi ngenxa ye-dephosphorization ye-phosphorus equlethe i-slag evela kwisithando somlilo sombane kunye nokongezwa kwe-ferroalloy LF refining. Ukushisa okuthephayo kwesithando sombane se-arc yi-1650 ~ 1670 ℃, kunye ne-eccentric bottom tapping (EBT) isetyenziselwa ukuthintela i-oxide slag ekungeneni kwi-LF yokucoca isithando somlilo.

(2)Emva kokucocwa kwe-LF, i-feeder ye-wire feeder i-0.20 ~ 0.25kg / t i-CA ecocekileyo yocingo lwensimbi ukuze i-denature ukungcola kwaye yenze ukubandakanywa kwintsimbi etyhidiweyo ibe yi-spherical. Emva konyango lwe-Ca, intsimbi etyhidiweyo ivuthelwa nge-argon ezantsi kwe-ladle ngaphezu kwemizuzu eyi-18. Amandla okuvuthela kwe-argon angenza ukuba intsimbi etyhidiweyo ingavezwa, ukwenzela ukuba ukubandakanywa kwe-spherical kwintsimbi etyhidiweyo ibe nexesha elaneleyo lokudada, ukuphucula ukucoceka kwentsimbi, kunye nokunciphisa impembelelo yokubandakanywa kwe-spherical kwi-low-temperature toughness. Umthamo wokutya we-CA wire ecocekileyo ingaphantsi kwe-0.20kg / t yensimbi, ukubandakanywa akukwazi ukuchithwa ngokupheleleyo, kwaye inani lokutya le-Ca wire lingaphezulu kwe-0.25kg / t yensimbi, eyongeza ngokubanzi iindleko. Ukongezelela, xa inani lokutya lomgca we-Ca likhulu, insimbi etyhidiweyo ibilisa ngamandla, kwaye ukuguquguquka kwenqanaba lensimbi etyhidiweyo kubangela ukuba insimbi etyhidiweyo ifakwe kwaye i-oxidation yesibini yenzeke.

(3)Unyango lwe-vacuum ye-VD: thumela i-lf esulungekileyo yentsimbi etyhidiweyo kwisikhululo se-VD kunyango lwe-vacuum, gcina i-vacuum engaphantsi kwe-65pa ngaphezu kwemizuzu engama-20 de i-slag iyeke ukukhupha ugwebu, vula isiciko sokufutha, kwaye uvuthele i-argon ezantsi kwe-ladle yokuvuthela okuzinzileyo kwentsimbi etyhidiweyo.

Ixesha lokuposa: Sep-02-2022