YuantaiDerunityhubhu ye-square rectangular inamalungelo omenzi angaphezu kwama-63, ahlangabezana nemigangatho yoshishino ekhaya nakwamanye amazwe. Imveliso idlule ngaphezu kwamakhonkco okuhlola angama-200 ukulawula umgangatho wemveliso.

"Ngokuqinisekileyo ungavumeli umbhobho wensimbi ongenakufaneleka kwimarike".

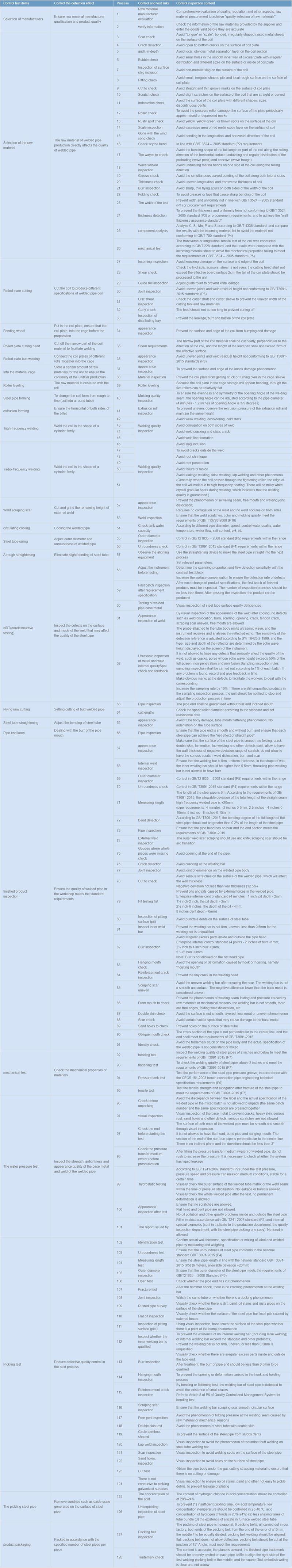

| Lawula izinto zovavanyo | Lawula umphumo wokufumanisa | Inkqubo | Ukulawula kunye nokuvavanya amakhonkco | Lawula umxholo wokuhlola |

| Ukukhethwa kwabavelisi | Qinisekisa isiqinisekiso somenzi wezinto ezikrwada kunye nomgangatho wemveliso | 1 | Uvavanyo lomenzi wezinto ezikrwada | Uvavanyo olubanzi lomgangatho, isidima kunye neminye imiba, ukuthengwa kwezinto ezikrwada ukuphumeza "ukukhethwa komgangatho wezinto eziluhlaza" |

| 2 | qinisekisa ulwazi | Jonga ulwazi lwemathiriyeli ekrwada ebonelelwe ngumthengisi kwaye ufake kwiyadi yempahla phambi kokuba ichaneke | ||

| Ukukhethwa kwemathiriyeli ekrwada | Izinto eziluhlaza zokuveliswa kombhobho odibeneyo zichaphazela ngokuthe ngqo umgangatho wombhobho odibeneyo | 3 | Ukujonga isiva | Kuphephe "ulwimi" okanye "isikali", idityanisiwe, iishiti zentsimbi eziphakanyiswe ngokungaqhelekanga kumphezulu wekhoyili. |

| 4 | Ukufunyanwa koqhekeko | Ziphephe iintanda ezisezantsi ezivulekileyo kumphezulu wepleyiti yekhoyili | ||

| 5 | uphicotho-nzulu | Gwema indawo, intsimbi ecacileyo yokwahlula umaleko kwicandelo lekhoyili | ||

| 6 | Ukukhangela ibubble | Kuphephe imingxunya emincinci eludongeni lwangaphakathi olugudileyo lwepleyiti ejikelezayo kunye nokusabalalisa okungaqhelekanga kunye nobukhulu obahlukeneyo kumphezulu okanye ngaphakathi kwepleyiti yekhoyili. | ||

| 7 | Ukuhlolwa kokubandakanywa kwe-slag yomhlaba | Gwema i-slag engeyiyo yensimbi ebusweni bekhoyili | ||

| 8 | Ukujonga umngxuma | Yiphephe imingxunya emincinci, engaqhelekanga kunye nomhlaba orhabaxa kumphezulu wepleyiti yekhoyili | ||

| 9 | Sika ukujonga | Ziphephe iingongoma ezithe tye nezicekethekileyo zegroove kumphezulu wepleyiti yekhoyili | ||

| 10 | Qwalasela | Gwema imikrwelo emincinci kumphezulu wekhoyili ethe tye okanye egobileyo | ||

| 11 | Ukujongwa kwe-Indent | Gwema umphezulu weplate yekhoyili enemilo eyahlukeneyo, ubungakanani, amazinyo angapheliyo | ||

| 12 | Roller check | Ukuze ugweme umonakalo we-roller yoxinzelelo, umphezulu weplate ngezikhathi ezithile uvela amanqaku aphakanyisiweyo okanye adandathekileyo | ||

| 13 | Ukujonga indawo enomhlwa | Gwema amabala atyheli, atyheli-luhlaza, okanye amdaka kumphezulu wekhoyili | ||

| 14 | Ukuhlolwa kwesikali | Gwema indawo egqithisileyo yomaleko we-oxide yentsimbi ebomvu kumphezulu wekhoyili | ||

| 15 | Uhambile nokukhangela ingoma yomoya | Gwema ukugoba kwi-longitudinal kunye ne-horizontal direction yekhoyili | ||

| 16 | Jonga ukugoba kwescythe | Ngokuhambelana neemfuno ze-GB/T 3524 -- 2005 standard (P2). | ||

| 17 | Amaza ukujonga | Kuphephe ukugoba imilo yobude obupheleleyo okanye inxalenye yekhoyili ecaleni kwendlela yokuqengqeleka yomphezulu othe tyaba ongaguquguqukiyo kunye nosasazo oluqhelekileyo lokuphumayo (incopho yamaza) kunye neconcave (umkhombe wamaza) | ||

| 18 | Uhlolo lokushwabana kwamaza | Kuphephe ukugoba kwe-marina kwelinye icala lekhoyili ecaleni kwendlela yokuqengqeleka | ||

| 19 | Groove check | Kuphephe ukugoba ngaxeshanye okugobileyo kwekhoyili kumacala omabini asecaleni | ||

| 20 | Ukujonga ukutyeba | Kuphephe ukungalingani kobude kunye nobungqingqwa bekhoyili | ||

| 21 | Burr ukuhlolwa | Gwema ii-spurs ezibukhali, ezincinci ezibhabhayo kumacala omabini obubanzi bekhoyili | ||

| 22 | Itshekhi esongwayo | Ukunqanda ukukrazuka okanye ukujikeleza okubangela ukugoba okubukhali kwekhoyili | ||

| 23 | Ububanzi bovavanyo | Ukuthintela ububanzi kunye nokufana okungahambelaniyo ne-GB/T 3524 -- 2005 standard (P4) okanye iimfuno zokuthengwa kwempahla. | ||

| 24 | ukufumanisa ubukhulu | Ukuthintela ubukhulu kunye nokufana nokungahambelani ne-GB/T 3524 -- 2005 standard (P3) okanye iimfuno zokuthengwa kwempahla, kunye nokufezekisa "umgangatho wokuqinisekisa ubungakanani bodonga" | ||

| 25 | uhlalutyo lwecandelo | Hlalutya i-C, i-Si, i-Mn, i-P kunye ne-S ngokwemigangatho ye-GB / T 4336, kwaye uthelekise iziphumo kunye noluhlu lwezinto ezingenayo ukuphepha izinto eziphathekayo ezingahambelani ne-GB / T 700 standard (P4) | ||

| 26 | uvavanyo lomatshini | Uvavanyo lwe-transverse okanye longitudinal tensile ye-coil luqhutywe ngokwe-GB / T 228 standard, kwaye iziphumo zafaniswa nephepha lezinto ezingenayo ezingenayo ukuphepha iipropathi zomatshini ezihlulekayo ukuhlangabezana neemfuno ze-GB / T 3524 --2005 standard (P5). | ||

| Ukusika ipleyiti eqengqelekayo | Sika ikhoyili ukuvelisa iinkcukacha ezahlukeneyo zekhoyili yombhobho odityanisiweyo | 27 | Uhlolo olungenayo | Kuphephe ukunkqonkqoza umonakalo kumphezulu kunye nomda wekhoyili |

| 28 | Chear check | Khangela i-scissors ye-hydraulic, i-shear ayifani, intloko yokusika ayiyi kudlula umgangatho webhodi osebenzayo 2cm, umsila we-coil plate kufuneka uqhutywe kwiyunithi. | ||

| 29 | Ukuhlolwa koluhlu lwesikhokelo | Lungisa i-roller yesikhokelo ukuthintela ukuvuza kweemela | ||

| 30 | Ukuhlolwa ngokubambisana | Kuphephe ukuhlangana okungafaniyo kunye nokuphakama okushiyekileyo kwe-weld okungahambelani nemigangatho ye-GB/ T3091-2015 (P8) | ||

| 31 | Ukuhlolwa kwe-disc shear | Jonga i-cutter shaft kunye ne-cutter sleeve ukukhusela ububanzi obungalinganiyo besixhobo sokusika kunye nezinto eziluhlaza | ||

| 32 | Itshekhi egobileyo | Ukutya akufuneki kube mde kakhulu ukuthintela ukugoba | ||

| 33 | Ukuhlolwa kwe-tray yokuhambisa | Thintela ukuvuza, i-burr kunye ne-buckle ye-coil plate | ||

| Ivili lokutya | Faka kwipleyiti yekhoyili, qinisekisa ukuba ipleyiti yekhoyili, ingene ekhejini phambi kokulungiswa | 34 | ukuhlolwa kwembonakalo | Thintela umphezulu kunye nomphetho wekhoyili ekuqhumeni kunye nomonakalo |

| Intloko yokusika ipleyiti eqengqelekisiweyo | Sika inxalenye encinci yezinto zekhoyili ukuququzelela i-welding | 35 | Iimfuno zokucheba | Inxalenye emxinwa yesixhobo sekhoyili iya kusikwa ngokucocekileyo, i-perpendicular ukuya kwicala lekhoyili, kwaye ubude becala elikhokelayo abuyi kudlula i-2cm yendawo esebenzayo. |

| Welding ipleyiti eqengqelekayo ngeempundu | Xhuma iipleyiti zekhoyili zemiqulu eyahlukeneyo Ndawonye kwi-cage | 36 | ukuhlolwa kwembonakalo | Kuphephe ukuhlangana okungafaniyo kunye nokuphakama okushiyekileyo kwe-weld okungahambelani nemigangatho ye-GB/ T3091-2015 (P8) |

| Kwindlwana yezinto eziphathekayo | Gcina isixa esithile semathiriyeli ekrwada yeyunithi ukuqinisekisa ukuqhubeka kwemveliso yeyunithi yeCar | 37 | ukuhlolwa kwembonakalo | Ukuthintela umphezulu kunye nomphetho wesiganeko somonakalo wokunkqonkqoza |

| 38 | Ukuhlolwa kwezinto | Thintela ipleyiti yekhoyili ekubeni ibambeke okanye ijike kumkhono wekheji | ||

| Umgangatho werola | Impahla ekrwada igxile kumqulu | 39 | Umgangatho werola | Ngenxa yokuba ipleyiti yekhoyili kwindawo yokugcina ikheji iya kubonakala igoba, ngokusebenzisa iirola ezintlanu zinokuba tyaba |

| Ukwenza umbhobho wentsimbi | Ukutshintsha ifom yekhoyili ukusuka kwi-rough ukuya kwi-coil ibe yityhubhu engqukuva) | 40 | Ukuhlolwa komgangatho wokubumba | Ukuqinisekisa ukulingana kunye ne-symmetry yokuvula i-Angle ye-welding seam, i-Angle yokuvula inokulungiswa ngokuhambelana nobubanzi bombhobho. (imizuzu emi-4 - i-intshi eyi-1.2 yokuvula i-Angle yi-3-5 degrees) |

| ukwenziwa kwe-extrusion | Qinisekisa ukuthe tye kwamacala omabini ebhilithi | 41 | Ukuhlolwa kwe-Extrusion roll | Ukuthintela ukungalingani, jonga uxinzelelo lwe-extrusion ye-extrusion roll kwaye ugcine ukuphakama okufanayo |

| welding ephezulu-frequency | Weld ikhoyili kwimilo yesilinda ngokuqinileyo | 42 | Ukuhlolwa komgangatho we-welding | Kuphephe i-welding ebuthathaka, i-desoldering, i-stack ebandayo |

| 43 | Kuphephe ukubola kumacala omabini e-weld | |||

| 44 | Kuphephe ukuqhekeka kwe-weld kunye nokuqhekeka okumileyo | |||

| 45 | Kuphephe ukubunjwa komgca we-weld | |||

| welding radio-frequency | Weld ikhoyili kwimilo yesilinda ngokuqinileyo | 46 | Ukuhlolwa komgangatho we-welding | Kuphephe ukubandakanywa kwe-slag |

| 47 | Ukuthintela iintanda ngaphandle kwe-weld | |||

| 48 | Kuphephe ukushwabana kweengcambu | |||

| 49 | Kuphephe ukungena kweengcambu | |||

| 50 | Kuphephe ukusilela ukudibanisa | |||

| 51 | Kuphephe ukuvuza ukuwelda, ukuwelda ubuxoki, i-lap welding kunye nezinye izinto. (Ngokuqhelekileyo, xa ikhoyili idlula kwi-roller yokuqinisa, i-edge yekhoyili iya kunyibilika ngenxa yokufudumeza okuphezulu. | |||

| Weld ukukrwela isiva | Sika kwaye ugaye ukuphakama okuseleyo kwe-weld yangaphandle | 52 | ukuhlolwa kwembonakalo | Thintela isenzeko se-swiveling seam, umlomo okhululekileyo kunye ne-welding joint dislocation; Ifuna akukho corrugation weld kwaye akukho maqhuqhuva weld kumacala omabini. |

| 53 | Ukuhlolwa kwe-weld | Qinisekisa ukuba imikrwelo ye-weld, umbala kunye nomgangatho wokubumba uhlangabezana neemfuno ze-GB/ T13793-2008 (P10) | ||

| ukupholisa okujikelezayo | Ukupholisa umbhobho odityanisiweyo | 54 | Jonga umthamo wamanzi etanki | Ngokutsho kobubanzi bombhobho ohlukeneyo, isantya, ukulawula umgangatho wamanzi, ubushushu bamanzi, ukuhamba kwamanzi, umxholo wetyuwa, i-pH, njl |

| Ubungakanani betyhubhu yentsimbi | Lungisa i-diameter yangaphandle kunye nokungajikelezi kombhobho odibeneyo | 55 | Ukuhlolwa kwedayimitha yangaphandle | Ulawulo kwi-GB/T21835 -- 2008 umgangatho (P5) iimfuno ngaphakathi koluhlu |

| 56 | Ukujonga ukungarhangqi | Ukulawula kwiimfuno ze-GB/ T3091-2015 ezisemgangathweni (P4) ngaphakathi koluhlu | ||

| Ukolulwa okurhabaxa | Ukuphelisa ukugoba okuncinci kwetyhubhu yentsimbi | 57 | Jonga izixhobo zokulungelelanisa | Sebenzisa isixhobo sokulungisa ukwenza umbhobho wentsimbi ngqo kwinkqubo elandelayo |

| NDT(uvavanyo olungonakalisiyo) | Hlola iziphene kumphezulu kunye nangaphakathi kwi-weld ezinokuchaphazela umgangatho wombhobho wensimbi | 58 | Lungisa isixhobo phambi kovavanyo | Seta iiparamitha ezifanelekileyo; Ukumisela ubungakanani bokuskena kunye nobuntununtunu bokubona isiphene kunye nebhloko yovavanyo lochasaniso; Ukwandisa imbuyekezo yomhlaba ukuqinisekisa izinga lokubona iziphene |

| 59 | Ukuhlolwa kwebhetshi yokuqala emva kokucaciswa kokutshintshwa | Emva kokutshintshwa kwemveliso nganye, ibhetshi yokuqala yeemveliso ezigqityiweyo kufuneka ihlolwe. Inani lamasebe okuhlola kufuneka lingabi ngaphantsi kwesithathu. Emva kokuphumelela ukuhlolwa, imveliso inokuveliswa | ||

| 60 | Uvavanyo lwesiseko sombhobho odityanisiweyo | Ukuhlolwa okubonakalayo kokusilela komgangatho womphezulu wetyhubhu | ||

| 61 | Ukuhlolwa kwembonakalo ye-weld | Ngokuhlolwa okubonakalayo kokubonakala kwe-weld emva kokupholisa, akukho ziphene ezifana nokuchithwa kwe-weld, ukutshisa, ukukrazula, ukuvulwa, ukuqhekeka, ukuqhekeka kwe-tendon, ukukrazula isiva esingalinganiyo, umlomo okhululekile uvumelekile. | ||

| 62 | Ukuhlolwa kwe-Ultrasonic yentsimbi kunye ne-weld yangaphakathi i-qualitySpot isheke kunye nempendulo | I-probe eqhotyoshelwe kwi-tube body ikhupha i-ultrasonic wave, kwaye isixhobo sifumana kwaye sihlalutye i-echo ebonakalisiweyo. Uvakalelo lwereferensi yokufumanisa luhlengahlengiswa ngokwe-SY / T6423.2-1999, kwaye uhlobo, ubungakanani kunye nobunzulu bombonakaliso buchongwa ngukuphakama kwamaza echo eboniswe kwisikrini sesixhobo. Akuvumelekanga ukuba naziphi na iziphene ezichaphazela kakhulu umgangatho we-weld, ezifana nokuqhekeka, ii-pores ezinokuphakama kwe-echo wave kudlula i-50% yesikrini esipheleleyo, ukungangeni kunye nokungaxutywanga.Imithetho yokuhlola isampuli: ukuhlolwa kwesampuli kuya kwenziwa ngokwe-1% yebhetshi nganye. Ukuba kukho nayiphi na ingxaki efunyenweyo, bhala phantsi kwaye unike ingxelo ngexesha. Yenza amanqaku acacileyo kwiziphene ukuququzelela abasebenzi ukuba bajongane nezihambelanayo; Yandisa ireyithi yesampulu nge-10%. Ukuba kusekho iimveliso ezingafanelekanga kwinkqubo yokuhlola isampuli, iyunithi kufuneka yaziswe ukuba imise kwaye ilungelelanise inkqubo yokuvelisa ngexesha. | ||

| Ukusika isarha yokubhabha | Ukumisela ukusika umbhobho we-butt-welded | 63 | Ukuhlolwa kwemibhobho | Isiphelo sombhobho siya kuqinisekiswa ngaphandle kwe-burr kunye nomlomo othotyiweyo |

| 64 | ukusika ubude | Jonga i-speed roller diameter ngokomgangatho kwaye usete idatha efanelekileyo | ||

| Ukulungiswa kwetyhubhu yentsimbi | Lungisa ukugoba ityhubhu yentsimbi | 65 | ukuhlolwa kwembonakalo | Gwema umonakalo womzimba wetyhubhu, i-tube yomlomo we-tube isenzeko; Akukho ukufakwa kumphezulu wetyhubhu |

| Umbhobho ekupheleni ugcine | Ukujongana ne-burr yomlomo wombhobho | 66 | Ukuhlolwa kwemibhobho | Qinisekisa ukuba isiphelo sombhobho sigudileyo kwaye ngaphandle kwe-burr, kwaye uqinisekise ukuba umbhobho ngamnye wentsimbi unokufikelela "umphumo wombhobho othe ngqo". |

| ukuhlolwa kwemveliso egqityiweyo | Qinisekisa umgangatho wombhobho odibeneyo kwi-workshop uhlangabezana neemfuno eziqhelekileyo | 67 | ukuhlolwa kwembonakalo | Qinisekisa ukuba ubuso bombhobho wentsimbi bugudileyo, akukho ukusonga, ukuqhekeka, ulusu oluphindwe kabini, i-lamination, i-lap welding kunye nezinye iziphene zikhona, vumela ukuba ube nodonga olubanzi loluhlu lokutenxa olubi lwe-scratch, ungavumeli ukuba ube nomkrwelo onzulu, ukuchithwa kwe-weld, ukutshisa kunye nesiva. |

| 68 | Ukuhlolwa kweweld yangaphakathi | Qinisekisa ukuba i-welding bar iqinile, ubukhulu obufanayo, kwimilo yocingo, i-welding bar yangaphakathi kufuneka ibe phezulu kuno-0.5mm, umbhobho we-welding bar awuvumelekanga ukuba ube ne-burr. | ||

| 69 | Ukuhlolwa kwedayimitha yangaphandle | Ulawulo kwi-GB/T21835 -- 2008 umgangatho (P5) iimfuno ngaphakathi koluhlu | ||

| 70 | Ukujonga ukungarhangqi | Ukulawula kwiimfuno ze-GB/ T3091-2015 ezisemgangathweni (P4) ngaphakathi koluhlu | ||

| 71 | Ukulinganisa ubude | Ubude bombhobho wensimbi yi-6m. Ngokweemfuno ze-GB/ T3091-2015, ukutenxa okuvumelekileyo kobude obupheleleyo bomthungo othe tye we-weld welding pipe yi +20mm. (iimfuno zombhobho: imizuzu emi-4 - 2 intshi 0-5mm, 2.5 intshi - 4 intshi 0-10mm, 5 intshi - 8 intshi 0-15mm) | ||

| 72 | Ukubhaqa bend | Ngokutsho kwe-GB / T3091-2015, idigri yokugoba yobude obupheleleyo bombhobho wensimbi akufanele ibe mkhulu kune-0.2% yobude bombhobho wensimbi. | ||

| 73 | Ukuhlolwa kwemibhobho | Qinisekisa ukuba intloko yombhobho ayinayo i-burr kwaye icandelo lokugqibela lihlangabezana neemfuno ze-GB / T3091-2015 | ||

| 74 | Ukuhlolwa kweweld yangaphandle | I-weld scaring yangaphandle kufuneka isebenzise imela ye-arc, ukukrwela isiva kufuneka kube yi-arc transition. | ||

| 75 | Iigouges apho amaqhekeza ephela ayelahlekile ukujonga | Gwema ukuvula ekupheleni kombhobho | ||

| 76 | Ukufunyanwa koqhekeko | Kuphephe ukuqhekeka kwi-welding bar | ||

| 77 | Ukuhlolwa ngokubambisana | Gwema into edibeneyo kumzimba wombhobho odibeneyo | ||

| 78 | Sika ukujonga | Gwema imikrwelo enzulu ebusweni bombhobho odibeneyo, oya kuchaphazela ubuninzi bodonga. Ukutenxa okungalunganga kungabi ngaphantsi kobunzima bodonga (12.5%) | ||

| 79 | Umngxuma wokuvavanya umcaba | Ukuthintela imingxuma kunye nemigodi ebangelwa amandla angaphandle kumbhobho odibeneyo. Umgangatho wolawulo lwangaphakathi lweshishini (imizuzu emi-4 - 1 intshi, ubunzulu bomgodi <2mm; 1¼ intshi-2 intshi, umngxuma ubunzulu <3mm; 2½ intshi-6 intshi, ubunzulu bomngxuma <4mm; Ubunzulu be-intshi ezisi-8 <6mm) | ||

| 80 | Ukuhlolwa kwendawo yokugalela (umngxuma) | Ziphephe izibonda zepunctate kumphezulu wetyhubhu yentsimbi | ||

| 81 | Jonga i-weld bar yangaphakathi | Ukuthintela i-welding bar ayiqini, ingalingani, ngaphantsi kwe-0.5mm ye-welding bar ayifanelekanga. | ||

| 82 | Burr ukuhlolwa | Gwema iindawo ezigqithisiweyo ezingaqhelekanga ngaphakathi nangaphandle kwentloko yombhobho. Umgangatho wolawulo lwangaphakathi lweshishini (iingongoma ezi-4 - ii-intshi ezi-2 ze-burr <1mm; 2½ intshi ukuya kwi 4 intshi burr <2mm; 5 "- 8" burr <3mm. Qaphela: IBurr ayivumelekanga kumbhobho oyintloko womnatha. | ||

| 83 | Ukukhangela umlomo ojingayo | Kuphephe ukuvuleka okanye ukuguqulwa okubangelwa yihuku okanye ukuphakanyiswa, oko kukuthi "umlomo wokuphakamisa" | ||

| 84 | Ukuqiniswa kokuhlolwa kokuqhekeka | Thintela intanda encinci kwi-welding bead | ||

| 85 | Ukukhuhla isiva singalingani | Kuphephe i-welding bar engalinganiyo emva kokukrazula isiva. Ibha ye-welding ayiyona indawo egudileyo ye-arc. Umahluko ongalunganga ongaphantsi kwesiseko sesinyithi uthathwa njengokungalingani | ||

| 86 | Ukusuka emlonyeni ukujonga | Thintela isenzeko sokusonga i-welding seam kunye noxinzelelo olubangelwa yimathiriyeli ekrwada okanye izizathu zoomatshini, ibha ye-welding ayigudi, kukho imiphetho yasimahla, ukusonga i-weld dislocation, njl. | ||

| 87 | Ukujonga ulusu kabini | Gwema umphezulu awugudi, unomaleko, inyama encinci okanye into engalinganiyo | ||

| 88 | Ukujonga isiva | Gwema amabala e-solder anokuthi enze umonakalo kwisiseko sesinyithi | ||

| 89 | Imingxuma yesanti ukujonga | Thintela imingxuma kumphezulu ityhubhu yentsimbi | ||

| 90 | Ukukhangela umlomo oblique | Icandelo lomnqamlezo lombhobho alikho i-perpendicular kumgca ophakathi, kwaye isiphelo siya kuhlangabezana neemfuno ze-GB / T3091-2015. | ||

| 91 | Ukujonga isazisi | Kuphephe uphawu lwentengiso oluxinanisiweyo kumzimba wombhobho kunye nenkcazo eyinyani yombhobho odityanisiweyo ayihambelani okanye ixutywe. | ||

| uvavanyo lomatshini | Qwalasela iimpawu zoomatshini bemathiriyeli | 92 | ukugoba uvavanyo | Hlola umgangatho we-welding wemibhobho yensimbi yee-intshi ezi-2 nangaphantsi ukuze uhlangabezane neemfuno ze-GB / T3091-2015 (P7) |

| 93 | uvavanyo olucaba | Ukujonga umgangatho we-welding wemibhobho yensimbi ngaphezu kwee-intshi ezi-2 kwaye uhlangabezane neemfuno ze-GB / T3091-2015 (P7) | ||

| 94 | Uvavanyo lwetanki yoxinzelelo | Vavanya ukusebenza kwegroove yoxinzelelo lombhobho wentsimbi, ngokuhambelana ne-CECS 151-2003 yomsele wodibaniso lweemfuno zobuchwephesha bobuchwephesha (P9) | ||

| 95 | uvavanyo lokuqina | Ukuvavanya amandla okuqina kunye nobude emva kokuphuka kombhobho wensimbi ukuhlangabezana neemfuno ze-GB / T3091-2015 (P7) | ||

| Uvavanyo loxinzelelo lwamanzi | Hlola amandla, umoya kunye nomgangatho wokubonakala kwesiseko sesinyithi kunye ne-weld yombhobho odibeneyo | 96 | Jonga phambi kokukhulula | Kuphephe ukungafani phakathi kweleyibhile kunye neenkcukacha zokwenyani zombhobho odityanisiweyo okanye ibhetshi edibeneyo ayivumelekanga ukuba ikhuphe (inombolo yebhetshi efanayo kunye neenkcukacha ezifanayo zicinezelwe kunye. |

| 97 | ukuhlolwa okubonakalayo | Ukuhlolwa okubonakalayo kwesiseko sesinyithi ukukhusela iintanda, ulusu olunzima, umhlwa onzima, imingxuma yesanti kunye nezinye iziphene, imikrwelo enzulu ayivumelekanga. | ||

| 97 | Jonga isiphelo phambi kokuba uqalise uvavanyo | Umphezulu wazo zombini iziphelo zombhobho odityanisiweyo kufuneka ube bushelelezi kwaye ugudileyo ngokuhlolwa okubonakalayo. Akuvumelekanga ukuba nentloko ecaba, igobe umbhobho kunye nomlomo ojingayo. Icandelo lesiphelo sombhobho we-non-burr li-perpendicular kumgca ophakathi. Akukho nqwelo-moya ethambekileyo kwaye ukutenxa kufuneka kube ngaphantsi kwe-3 ° | ||

| 98 | Jonga indawo yokuhambisa uxinzelelo (amanzi) phambi koxinzelelo | Emva kokuzalisa i-medium transfer transfer pressure (amanzi) wombhobho odibeneyo, musa ukukhawuleza ukunyusa uxinzelelo. Kuyimfuneko ukujonga ukuba ngaba inkqubo inokuvuza kolwelo | ||

| 99 | uvavanyo lwe-hydrostatic | Ngokutsho kwe-GB/ T241-2007 standard (P2) phantsi koxinzelelo lovavanyo, isantya soxinzelelo kunye neemeko zokuhambisa uxinzelelo, uzinzile ixesha elithile. Jonga ngokubonakalayo umphezulu wangaphandle we-welded tube matrix okanye i-weld seam ngaphakathi kwexesha lokuzinza koxinzelelo. Akukho kuvuza okanye ukugqabhuka kuvunyelwe. Jonga ngokubonakalayo umbhobho odibeneyo emva kovavanyo, akukho deformation esisigxina evunyelwe | ||

| 100 | Ukuhlolwa kwembonakalo emva kovavanyo | Qinisekisa ukuba akukho mikrwelo ivumelekileyo; Intloko ecaba kunye nombhobho ogobileyo awuvumelekanga. Akukho ukungcola kweoli kunye nezinye iingxaki ezisemgangathweni ngaphakathi nangaphandle kombhobho wensimbi | ||

| 101 | Ingxelo ekhutshwe ngu | Gcwalisa ngokungqongqo ngokuhambelana nomgangatho we-GB / T241-2007 (P2) kunye nemizekelo ekhethekileyo yangaphakathi (ithunyelwe ngokuphindwe kathathu kwisebe lemveliso, isebe lokuhlola umgangatho, kunye nombhobho wensimbi uchola ikopi enye). Akukho buqhophololo buvumelekileyo | ||

| Uvavanyo lokukha | Nciphisa ulawulo lomgangatho osisiphene kwinkqubo elandelayo | 102 | Uvavanyo lokuchongwa | Qinisekisa ubungqingqwa bokwenene bodonga, ukuchazwa okanye ukuxutywa kwelebhile kunye nombhobho odityanisiweyo ngokulinganisa kunye nobunzima |

| 103 | Uvavanyo lokungajikelezi | Qinisekisa ukuba ukungahambi kakuhle kombhobho wensimbi kuhambelana nomgangatho wesizwe we-GB / T 3091-2015 (P4) | ||

| 104 | Uvavanyo lobude bokulinganisa | Qinisekisa ubude bombhobho wensimbi ngokuhambelana nomgangatho wesizwe we-GB / T 3091-2015 (P5) (iimitha ezi-6, ukuphambuka okuvumelekileyo + 20mm) | ||

| 105 | Ukuhlolwa kwedayimitha yangaphandle | Qinisekisa ukuba ububanzi bangaphandle bombhobho wensimbi buhlangabezana neemfuno ze-GB / T21835 --2008 Standard (P5) | ||

| 106 | Vula uvavanyo | Khangela ukuba isiphelo sombhobho sinqumle isenzeko | ||

| 107 | Uvavanyo lokwaphuka | Emva kokutshatyalaliswa kwesando, akukho nto iqhekezayo kwi-welding bar | ||

| 108 | Ukuhlolwa ngokubambisana | Jonga ityhubhu efanayo ukuba kukho i-docking phenomenon | ||

| 109 | Uphando lwemibhobho eruliweyo | Jonga ngokubonakalayo ukuba kukho ukungcola, ipeyinti, amabala e-oyile kunye nemibhobho erusayo kumphezulu wombhobho wentsimbi | ||

| 110 | Ukuhlolwa komngxuma ocaba | Jonga ngokubonakalayo ukuba ubuso bombhobho wensimbi unemingxuma yendawo ebangelwa amandla angaphandle | ||

| 111 | Ukuhlolwa kwendawo yokugalela (imingxuma) | Ukusebenzisa uhlolo olubonakalayo, bamba isandla kumphezulu wombhobho wentsimbi nokuba kukho inqaku le-bump phenomenon | ||

| 112 | Hlola ukuba ngaba i-welding bar yangaphakathi ifanelekile | Ukuthintela ubukho be-welding bar yangaphakathi (kubandakanywa i-welding yobuxoki) okanye ibha ye-welding yangaphakathi idlula umgangatho kunye nezinye iingxaki; Ukuthintela i-welding bar ayiqini, ingalingani, okanye ngaphantsi kwe-0.5mm ayifanelekanga | ||

| 113 | Burr ukuhlolwa | Jonga ngokujonga ukuba ngaba akhona na amalungu angaphezulu angaqhelekanga ngaphakathi nangaphandle kombhobho. Emva kokonyango, i-burr yokuphela kombhobho kufuneka ibe ngaphantsi kwe-0.5mm ukuze ifaneleke | ||

| 114 | Ukuhlolwa komlomo ojingayo | Ukuthintela ukuvulwa okanye ukuguqulwa okubangelwa kwi-hook kunye nenkqubo yokunyusa | ||

| 115 | Ukuqiniswa kokuhlolwa kokuqhekeka | Ngokugoba okanye uvavanyo oluthe tyaba, ibha ye-welding yombhobho wensimbi ifunyenwe ukuphepha ubukho beentanda ezincinci. Jonga kwiNqaku le-8 ye-P6 yoLawulo loMgangatho kunye neNkqubo yoLawulo lokuvavanya ukugoba | ||

| 116 | Ukuhlolwa kwesiva | Qinisekisa ukuba i-welding bar ekhuhla isiva egudileyo, engqukuva | ||

| 117 | Uhlolo lwezibuko lwasimahla | Gwema isenzeko soxinzelelo lokusonga kwi-welding seam ebangelwa yizinto eziluhlaza okanye izizathu zoomatshini | ||

| 118 | Uvavanyo lwesikhumba kabini | Gwema i-phenomenon ye-tube yensimbi enesikhumba esiphindwe kabini | ||

| 119 | Yenza isangqa se-bamboo | Ukuthintela ubuso bombhobho wensimbi kwi-slubby dents | ||

| 120 | Ukuhlolwa kwe-lap weld | Ukuhlolwa okubonakalayo ukuphepha isenzeko sokudityaniswa kwe-butt welding kwi-steel tube welding bar | ||

| 121 | Ukuhlolwa kwesilonda | Ukuhlolwa okubonakalayo ukuphepha amabala e-welding ebusweni bombhobho wensimbi | ||

| 122 | Imingxuma yesanti, ukuhlolwa | Ukuhlolwa okubonakalayo ukuphepha imingxuma kumphezulu wepayipi yensimbi | ||

| 123 | Sika uvavanyo | Fumana umzimba wombhobho phantsi kwezinto zokuqhawula igesi ukuze uqiniseke ukuba akukho ukusika okanye umonakalo | ||

| 124 | Akukho nto incedayo ukuchola iisundries ezifakwe igalvanized | Ukuhlolwa okubonakalayo ukuqinisekisa ukuba akukho mabala e-oyile, ipeyinti kunye nokunye okungelula ukucoca inkunkuma, ukunqanda ukuvuza kwe-plating. | ||

| Umbhobho wentsimbi wokuchola | Susa iisundries ezifana nesikali se-oxide esenziwe kumphezulu wombhobho wentsimbi | 125 | Ukuxinwa kwe-asidi | Umxholo we-hydrogen chloride kwi-acid concentration kufuneka ilawulwe kwi-20% -24% |

| 126 | Ukuhlolwa kwe-underpickling yombhobho wentsimbi | Ukuthintela (1) ukungonelanga kwexesha lokuchola, ubushushu obuphantsi be-asidi, uxinzelelo oluphantsi (ubushushu kufuneka bulawulwe kwi-25-40 ℃, ukuxinwa kwe-asidi ye-hydrogen chloride yi-20% -24%) (2) amaxesha angaphantsi kokungcangcazela kwe-tube bundle (3) ubukho be-silicate kwityhubhu yentsimbi edityanisiweyo. | ||

| ukupakishwa kwemveliso | Ipakishwe ngokuhambelana nenani elichaziweyo lemibhobho yensimbi nganye | 127 | Ukuhlolwa kwebhanti yokupakisha | Ukupakishwa kombhobho wensimbi kune-hexagonal, amabhanti okupakisha ama-6, onke aqhutywe kwifektri yethu, zombini iziphelo zebhanti yokupakisha ukusuka ekupheleni kwephutha le-± 10mm, i-4 ephakathi iya kwahlulwa ngokulinganayo, ukupakisha ibhanti ye-welding kufuneka ilungelelaniswe, i-flat, ibhanti yokupakisha ayivumeli ukuphambuka, ibhanti lokupakisha kufuneka linqunyulwe kwi-45 ° kwi-junction. |

| 128 | Ukukhangela uphawu lwentengiso | Umxholo uchanekile, inqwelomoya iphezulu, uphawu lokuthengisa lombhobho ogqityiweyo kufuneka luncanyathiselwe ngokufanelekileyo kwibhaffle yombhobho ngamnye ukulungelelanisa icala lasekunene lebhanti yokupakisha yokuqala embindini, kunye nomthombo weTed embellish ukubhala ucacile kwaye awubuzi. |