There are many sizes of black square pipes. So black square tube is widely used in construction, machinery manufacturing, steel structure engineering, shipbuilding, solar power stents, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain wall building, highway, rail, airports, boiler, building construction, pressure vessels, storage tanks, Bridges, power station equipment, lifting transportation machinery such as load of welded structure, etc.

Are you in search for high grade and standard rectangular hollow section? If yes, then you have landed in the right place. You can use HOT FINISH EN 10210 S235JRH SQUARE HOLLOW SECTION and install for your industrial application. This product is well-certified by ISO and its high quality ensures its 100% originality. Also, the raw material is used to make is first tested and then used to make it. This is one of the best and effective hollow section and sturdy as well. Only, for this reason, it is used in various industries for structural use. It is mostly used when the bridges and building are constructed.

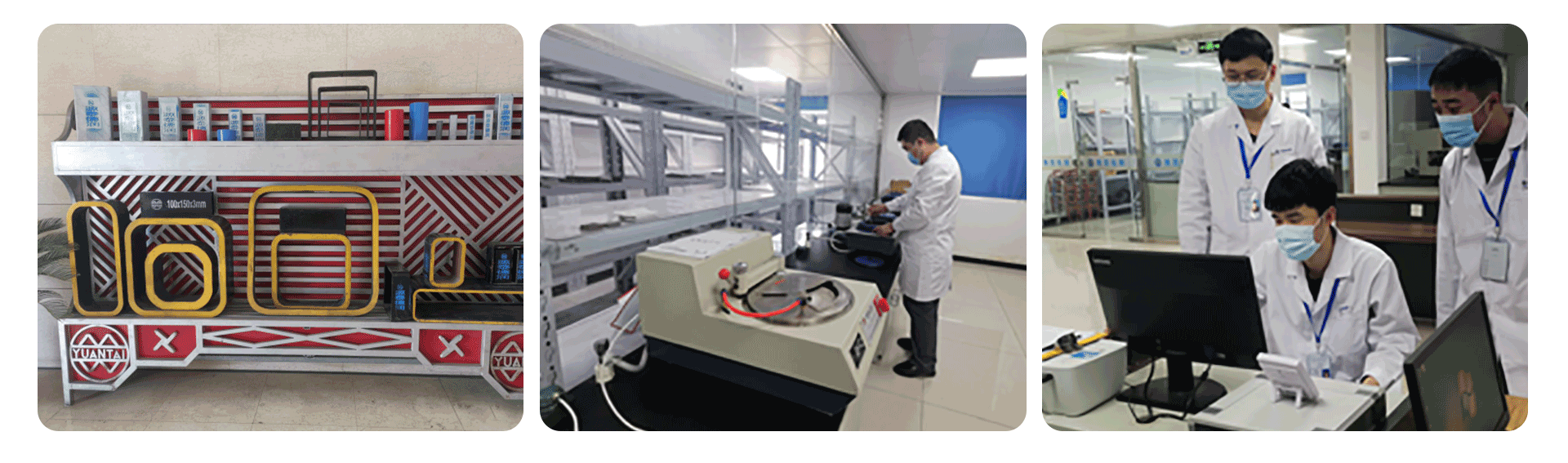

The product is tested by many experts in the approved labs to make sure its high-quality and durability. This means this hollow section is highly durable and reliable as well. These days, various industries are adopting it because of its features such as good conductivity, outstanding resistivity, sturdy in nature, good quality and many others. It is the great choice of industrialists for the last many years and it is always established in different version every year. The product is available in various sizes and shapes and in cut length as well.

So, now customers have an option of buying hollow section in accordance with their needs and suitability. It is also available at reasonable prices within the market. It can be purchased in bulk and in different quantity as per your needs. More the size, more the price, applies to this.

Welcome to contact Yuantai Derun, e-mail: sales@ytdrgg.com , real-time connection factory inspection or factory visit!

Specification of square and rectangular hollow section

EN 10210 S235JRH Hot Finish Square Hollow Section Chemical Composition

EN 10210 Hot Finish S235JRH Structural Square Hollow Section Mechanical Properties

A: We are factory.

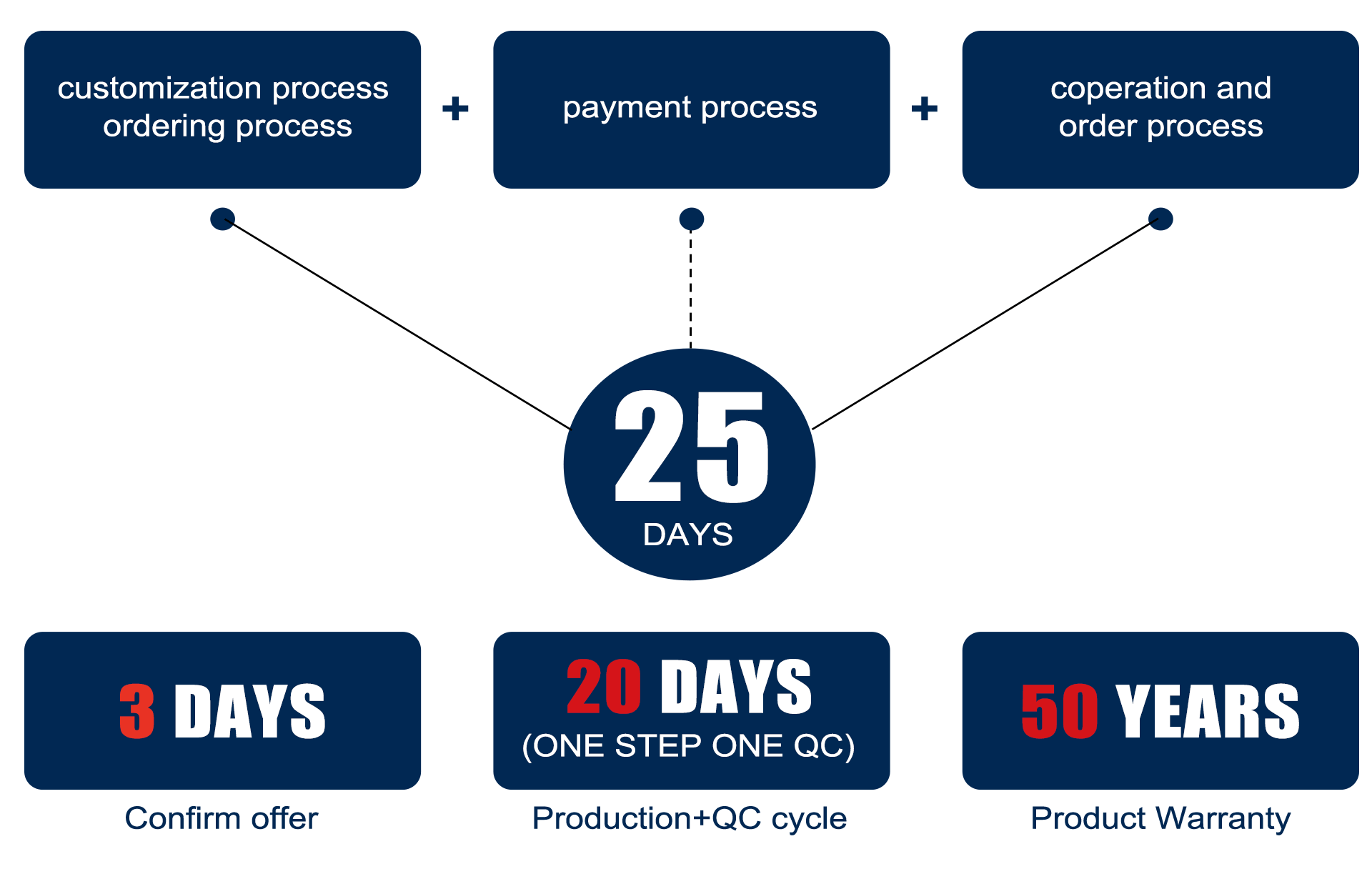

A: Generally it is 5-10 days if the goods are in stock. or it is 30 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge with the cost of freight paid by customer.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us as below

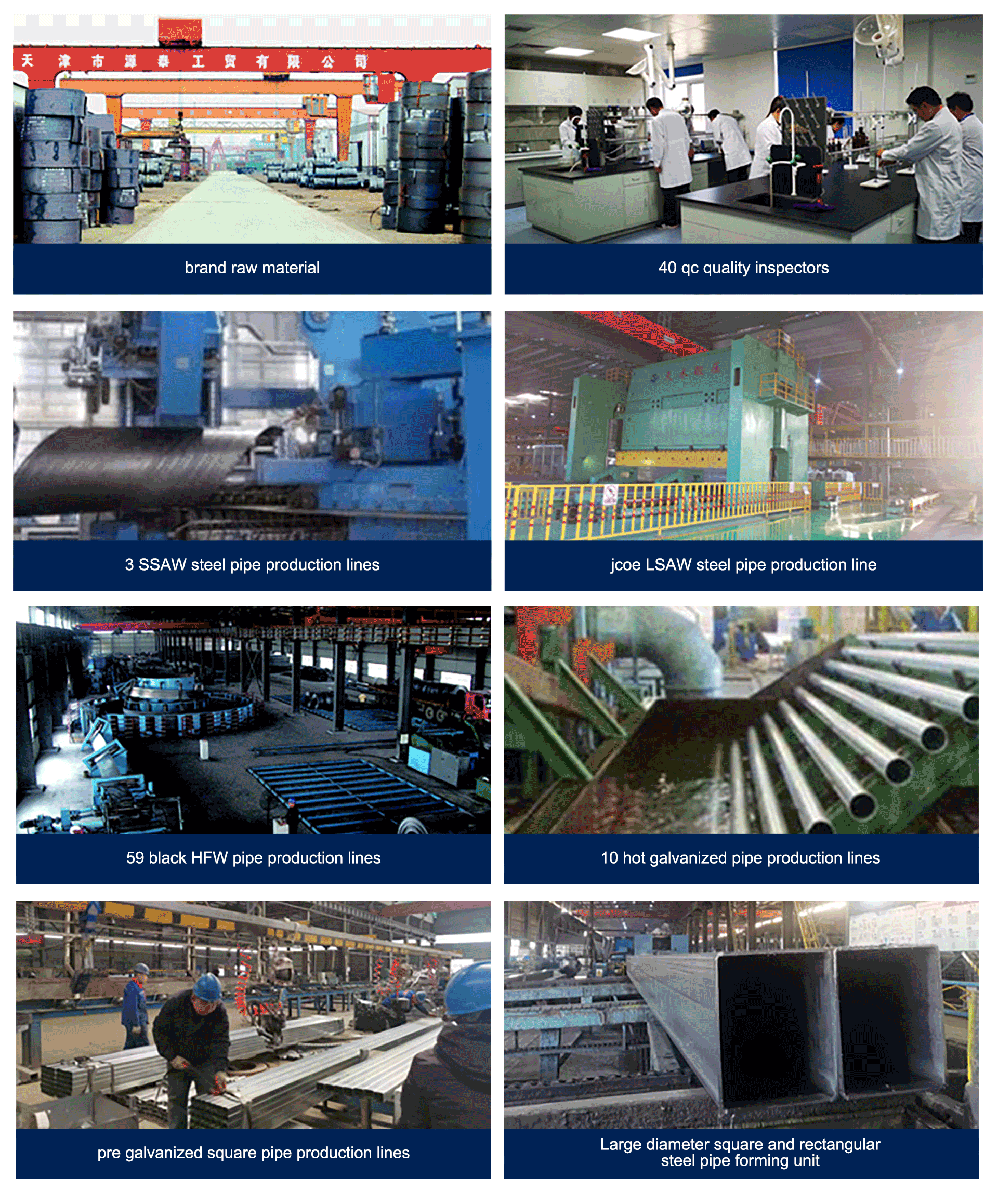

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

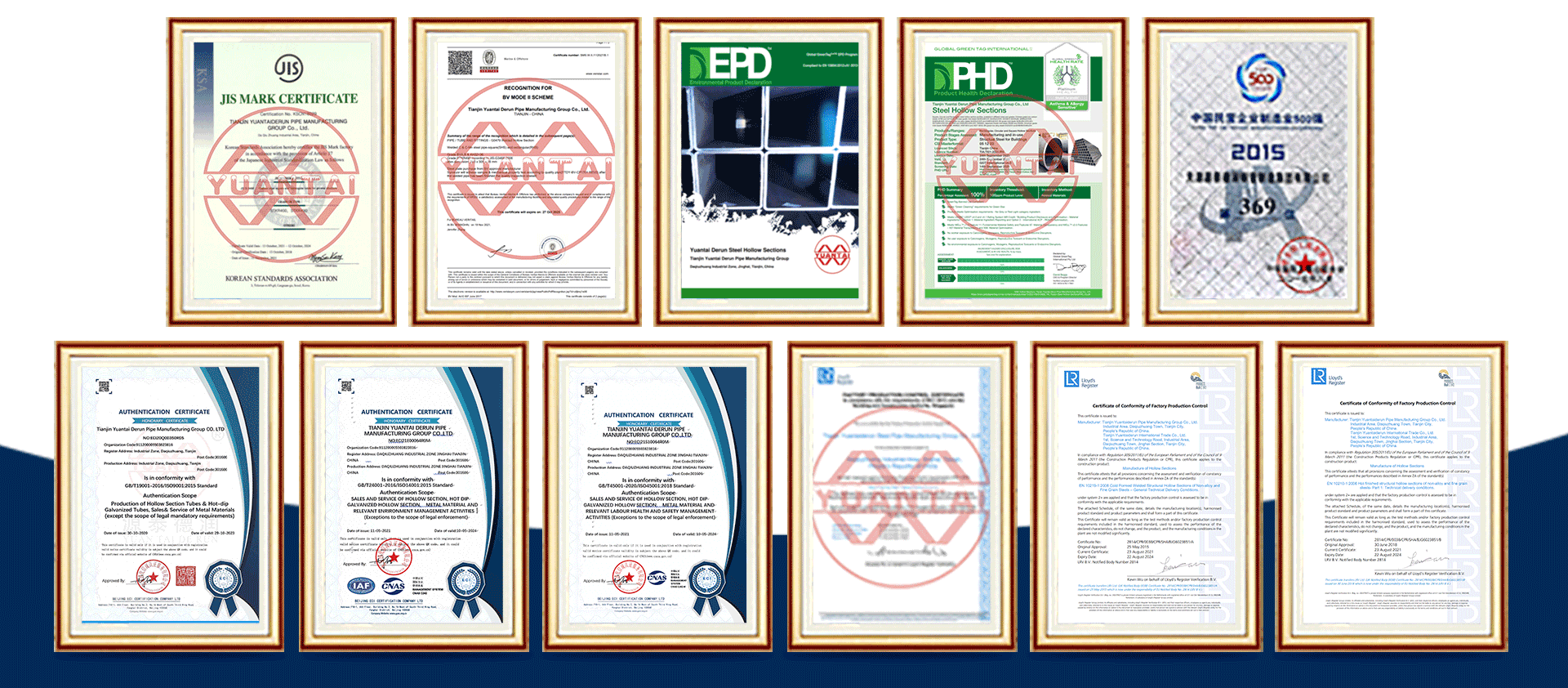

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821