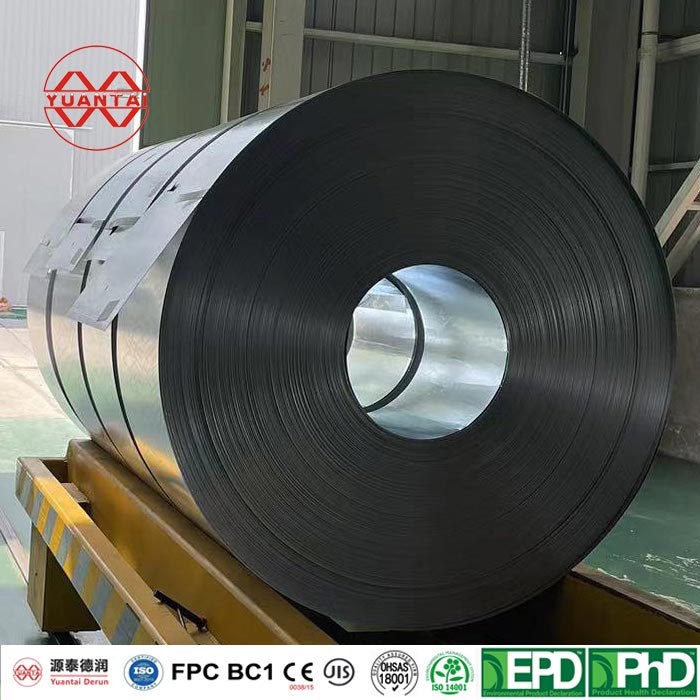

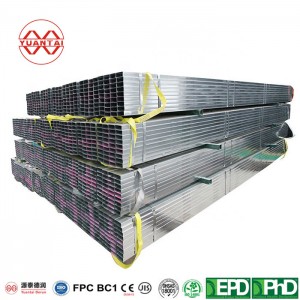

zinc aluminum magnesium coated steel coil|high corrosion resistance|high wear resistance|excellent toughness

Regarding zinc aluminum magnesium, everyone must be curious about this high-strength and lightweight metal. What is its origin?

To understand the past and present lives of zinc aluminum magnesium strip coils, it is necessary to start by understanding an ancient hot dip plating process. In China, it first appeared 3400 years ago. Strictly speaking, modern hot dip plating processes originated in Europe. Key technological points at that time;

》Zinc used for hot dip plating must be very pure and cannot come into contact with iron during the process;

》Verified the effects of ammonium chloride and zinc chloride;

》Application of small piece galvanizing and centrifugal equipment;

》Application of corrosion inhibitors;

》Lead can extend the lifespan of zinc pots;

》The change in zinc liquid temperature seriously affects the amount of zinc added to the workpiece;

》Developed zinc-rich paint.

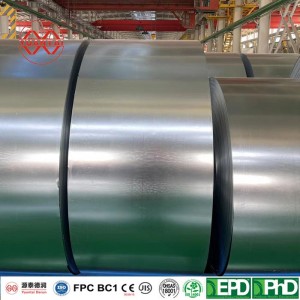

Since the new century, the newly developed hot dip plating process is "continuous Hot-dip galvanization of aluminum and magnesium for sheet and strip".

Commercial Application of Zinc Aluminum Magnesium Coated Steel Plate

After the 21st century, major steel mills in China, Europe, South Korea, Japan, Australia, and other countries have all launched their own zinc aluminum magnesium coating products. The coating composition and product characteristics have undergone differentiation and subdivision, and their applications have also been promoted from fields such as construction and light industry household appliances to automobiles. Domestic steel mills have started research and production, and in the future, with industrial upgrading, this product will be widely used and gradually replace galvanized products.

Performance characteristics of zinc aluminum magnesium steel coils

》Super strong corrosion resistance

The corrosion resistance of zinc aluminum magnesium steel plate is 5-10 times that of ordinary galvanized steel plate

》Wonderful self-healing

The cut after cutting will form a protective film with automatic sealing and repair function

》High hardness and wear resistance

The hardness is more than twice that of ordinary galvanized steel plate, with better scratch resistance and wear resistance

》Green environmental friendliness

Complies with the RoHS standards of the European Union and is currently internationally recognized as an environmentally friendly product

》Super strong rust prevention performance

The rust resistance is 15 times higher than that of ordinary galvanized sheet (reaching the standard of stainless steel)

》Excellent performance and easy processing

Has excellent processing properties such as stretching, stamping, bending, welding, etc., and is not prone to peeling during processing

》Super cost-effective

Multiple performance meets stainless steel standards, but the price is far lower than stainless steel

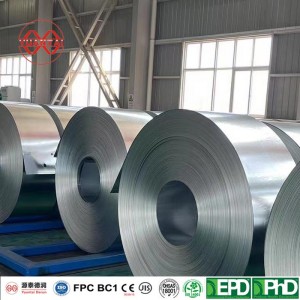

》Widely used in various fields

Suitable for various fields such as civil construction, agriculture and livestock production, railway roads, power communication, photovoltaic brackets, industrial refrigeration, etc

Application Engineering Cases of Zinc Aluminum Magnesium Steel Coil

Big Air Shougang, also known as "Snow Flying Sky", is located in the north area of Shougang Old Industrial Park, Shijingshan District, Beijing. It is the venue for Freestyle skiing and Snowboarding competitions in the 2022 Beijing Winter Olympics; It consists of three parts: the track, the referee tower, and the stands area, with a total of 6700 seats set up.

Specification Table for Zinc Aluminum Magnesium Steel Coils

The company attaches great importance to the quality of products, invests heavily in the introduction of advanced equipment and professionals, and goes all out to meet the needs of customers at home and abroad.

The content can be roughly divided into: chemical composition, yield strength, tensile strength, impact property, etc

At the same time, the company can also carry out on-line flaw detection and annealing and other heat treatment processes according to customer needs.

https://www.ytdrintl.com/

E-mail :sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd. is a steel pipe factory certified by EN/ASTM/ JIS specializing in the production and export of all kinds of square rectangular pipe, galvanized pipe, ERW welded pipe, spiral pipe, submerged arc welded pipe, straight seam pipe, seamless pipe, color coated steel coil, galvanized steel coil and other steel products.With convenient transportation, it is 190 kilometers away from Beijing Capital International Airport and 80 kilometers away from Tianjin Xingang.

Whatsapp:+8613682051821