I-YuantaiDerunithubhu elingunxande eliyisikwele linamalungelo obunikazi angaphezu kuka-63, ahlangabezana nezindinganiso zomkhakha ekhaya naphesheya. Umkhiqizo udlule izixhumanisi zokuhlola ezingaphezu kuka-200 ukuze ulawule ikhwalithi yomkhiqizo.

"Ngokuqinile ungavumeli ipayipi lensimbi elingafanelekile emakethe".

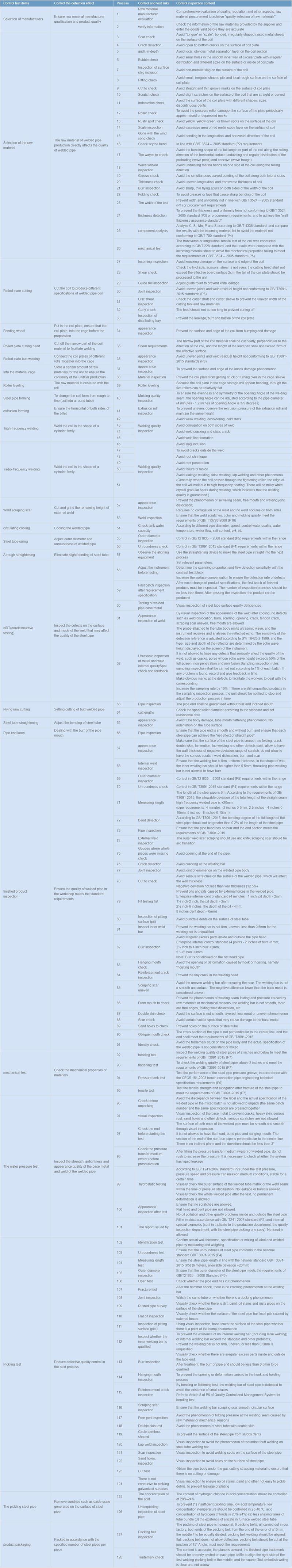

| Lawula izinto zokuhlola | Lawula umphumela wokuthola | Inqubo | Izixhumanisi zokulawula nokuhlola | Lawula okuqukethwe kokuhlola |

| Ukukhethwa kwabakhiqizi | Qinisekisa ukufaneleka komkhiqizi wezinto ezingavuthiwe kanye nekhwalithi yomkhiqizo | 1 | Ukuhlolwa komkhiqizi wezinto ezingavuthiwe | Ukuhlolwa okuphelele kwekhwalithi, idumela nezinye izici, ukuthengwa kwempahla eluhlaza ukuze kuzuzwe "ukukhethwa kwekhwalithi yezinto zokusetshenziswa" |

| 2 | qinisekisa ulwazi | Hlola ulwazi lwezinto ezingavuthiwe ezinikezwe umphakeli bese ufaka egcekeni lezimpahla ngaphambi kokuba zinembile | ||

| Ukukhethwa kwempahla eluhlaza | Impahla eluhlaza yokukhiqizwa kwamapayipi ahlanganisiwe ithinta ngqo ikhwalithi yepayipi elihlanganisiwe | 3 | Ukuhlola isibazi | Gwema "ulimi" noma "isikali", amashidi ensimbi aphakanyisiwe, anomumo ongavamile ebusweni bekhoyili |

| 4 | Ukutholwa komfantu | Gwema imifantu yethiphu phansi evulekile ebusweni be-coil plate | ||

| 5 | ukucwaninga ngokujulile | Gwema ungqimba lwasendaweni, olusobala lwensimbi oluhlukanisayo engxenyeni yekhoyili | ||

| 6 | Ukuhlola ibhamuza | Gwema izimbobo ezincane odongeni lwangaphakathi olubushelelezi lwepuleti eliyindilinga elinokusabalalisa okungajwayelekile kanye nosayizi abahlukene ngaphezulu noma ngaphakathi kwepuleti lekhoyili | ||

| 7 | Ukuhlolwa kokufakwa kwe-surface slag | Gwema i-slag engeyona eyensimbi ebusweni bekhoyili | ||

| 8 | I-pitting check | Gwema imigodi emincane emincane engajwayelekile kanye nendawo emagebhugebhu yasendaweni phezu kwe-coil plate | ||

| 9 | Sika ukuze uhlole | Gwema amamaki aqondile namancane endaweni ye-coil plate | ||

| 10 | Isheke lokuklwebha | Gwema imihuzuko emincane ebusweni bekhoyili eqondile noma egobile | ||

| 11 | Ukuhlola ukuhlehlisa | Gwema ingaphezulu lepuleti lekhoyili elinezimo ezihlukene, osayizi, amazinyo angapheli | ||

| 12 | Hlola i-roller | Ukuze ugweme ukulimala kwe-pressure roller, ingaphezulu lepuleti ngezikhathi ezithile livela amamaki aphakanyisiwe noma acindezelekile | ||

| 13 | Ukuhlola indawo egqwalile | Gwema amabala aphuzi, aphuzi-luhlaza, noma ansundu ebusweni bekhoyili | ||

| 14 | Ukuhlolwa kwesikali | Gwema indawo eyeqile yongqimba lwe-metal oxide ebomvu phezu kwekhoyili | ||

| 15 | Ihambe nokuhlola ingoma yomoya | Gwema ukugoba ohlangothini longitudinal kanye nendawo evundlile yekhoyili | ||

| 16 | Hlola ukugoba kwe-scythe | Ngokuvumelana nezimfuneko ze-GB/T 3524 -- 2005 ezijwayelekile (P2). | ||

| 17 | Amagagasi okuhlola | Gwema ukuma okugobayo kobude obugcwele noma ingxenye yekhoyili eduze kwendlela eginqikayo yendawo evundlile evundlile kanye nokusabalalisa okuvamile kokuphumela ngaphandle (indawo ephakeme yamagagasi) kanye ne-concave (i-wave trough) | ||

| 18 | Ukuhlola imibimbi yegagasi | Gwema ukugoba kwe-marina ohlangothini olulodwa lwekhoyili lapho iginqika khona | ||

| 19 | isheke Groove | Gwema ukugoba kanyekanye kwekhoyili emaceleni omabili | ||

| 20 | Ukuhlolwa kobukhulu | Gwema ukujiya okungalingani kwekhoyili nobude obuguquguqukayo | ||

| 21 | Ukuhlolwa kwe-Burr | Gwema ama-spurs acijile, amancane andizayo ezinhlangothini zombili zobubanzi bekhoyili | ||

| 22 | Isheke eligoqayo | Ukuze ugweme ama-creases noma ama-laps abangela ukugoba okubukhali kwekhoyili | ||

| 23 | Ububanzi bokuhlolwa | Vimbela ububanzi nokufana okungahambisani ne-GB/T 3524 -- 2005 standard (P4) noma izimfuneko zokuthenga | ||

| 24 | ukutholwa kokuqina | Ukuvimbela ukushuba nokufana ukuthi kungahambisani ne-GB/T 3524 -- 2005 standard (P3) noma izidingo zokuthengwa kwempahla, kanye nokufeza "izinga lokuqinisekisa ukushuba kodonga" | ||

| 25 | ukuhlaziywa kwengxenye | Hlaziya u-C, Si, Mn, P kanye no-S ngokwezinga le-GB/T 4336, bese uqhathanisa imiphumela nohlu lwezinto ezingenayo ukuze ugweme okokusebenza okungahambisani ne-GB/T 700 standard (P4) | ||

| 26 | ukuhlolwa komshini | Ukuhlola okuguquguqukayo noma okude kwekhoyili kwenziwa ngokwezinga le-GB/T 228, futhi imiphumela yaqhathaniswa neshidi lempahla engenayo ukuze kugwenywe izici zomshini zokwehluleka ukuhlangabezana nezimfuneko ze-GB/T 3524 -- 2005 standard (P5). | ||

| Ukusika ipuleti eligoqiwe | Sika ikhoyili ukuze ukhiqize imininingwane ehlukene yekhoyili yepayipi elishiselwe | 27 | Ukuhlola okungenayo | Gwema ukushaya umonakalo ebusweni nasonqenqemeni lwekhoyili |

| 28 | Shear shear | Bheka isikelo se-hydraulic, i-shear ayilingani, ikhanda lokusika akufanele lidlule indawo yebhodi esebenzayo engu-2cm, umsila wepuleti lekhoyili kufanele ucutshungulwe kuyunithi. | ||

| 29 | Ukuhlolwa komqulu womhlahlandlela | Lungisa i-roller yomhlahlandlela ukuze uvimbele ukuvuza kommese | ||

| 30 | Ukuhlola ngokuhlanganyela | Gwema amalunga angalingani nokuphakama okuyinsalela kwe-weld okungahambisani namazinga e-GB/ T3091-2015 (P8) | ||

| 31 | Ukuhlolwa kwe-disc shear | Hlola i-cutter shaft kanye nomkhono wokusika ukuze uvimbele ububanzi obungalingani bethuluzi lokusika nezinto zokusetshenziswa | ||

| 32 | Isheke eligobile | Isiphakeli akufanele sibe side kakhulu ukuvimbela ukugoqa | ||

| 33 | Ukuhlolwa kwethreyi lokusabalalisa | Vimbela ukuvuza, i-burr kanye nebhande le-coil plate | ||

| Isondo lokudla | Faka ku-coil plate, qinisekisa ukuthi i-coil plate, ekhejini ngaphambi kokulungisa | 34 | ukuhlolwa kokubukeka | Vimbela ingaphezulu kanye nonqenqema lwekhoyili ekuqhumeni nasekulimaleni |

| Ikhanda lokusika ipuleti eligoqiwe | Sika ingxenye encane yekhoyili ukuze kube lula ukushisela | 35 | Izidingo zokugunda | Ingxenye ewumngcingo yekhoyili izosikwa kahle, iqondane nesiqondiso sekhoyili, futhi ubude bengxenye yomthofu akumele budlule u-2cm wendawo esebenzayo. |

| I-Rolled plate butt welding | Xhuma izingcwecwe zekhoyili zamaroli ahlukene Ndawonye ekhejini | 36 | ukuhlolwa kokubukeka | Gwema amalunga angalingani nokuphakama okuyinsalela kwe-weld okungahambisani namazinga e-GB/ T3091-2015 (P8) |

| Ingene ekhejini lempahla | Gcina inani elithile lezinto zokusetshenziswa zeyunithi ukuze uqinisekise ukuqhubeka kokukhiqizwa kwe-unitCar | 37 | ukuhlolwa kokubukeka | Ukuvimbela ingaphezulu kanye nonqenqema lomonakalo wokugoqa |

| 38 | Ukuhlolwa kwezinto | Vimbela i-coil plate ukuthi ingabambeki noma iphenduke kumkhono wekheji | ||

| I-roller leveling | Impahla eluhlaza igxile phakathi nomqulu | 39 | I-roller leveling | Ngenxa yokuthi i-coil plate endaweni yokugcina yekheji izovela igobile, ngama-roller amahlanu angaba flat |

| Ukwakhiwa kwepayipi lensimbi | Ukushintsha ifomu lekhoyili lisuka kumaholoholo liye kwelincane (ikhoyili libe yishubhu eliyindilinga) | 40 | Ukuhlolwa kwekhwalithi yokubumba | Ukuqinisekisa ukulingana nokulinganisa kwe-Angle yokuvula ye-welding seam, i-Angle yokuvula ingashintshwa ngokuvumelana nobubanzi bepayipi. (Imizuzu emi-4 - 1.2 amayintshi wokuvula i-engeli ingu-3-5 degrees) |

| ukwakhiwa kwe-extrusion | Qinisekisa ukuthi izinhlangothi zombili ze-billet zivundlile | 41 | Ukuhlolwa kwe-Extrusion roll | Ukuze uvimbele ukungalingani, bheka ingcindezi ye-extrusion ye-extrusion roll futhi ugcine ukuphakama okufanayo |

| high-frequency welding | Weld ikhoyili ngendlela yesilinda ngokuqinile | 42 | Ukuhlolwa kwekhwalithi yokushisela | Gwema i-welding ebuthakathaka, i-desoldering, isitaki esibandayo |

| 43 | Gwema ukubola ezinhlangothini zombili ze-weld | |||

| 44 | Gwema ukuqhekeka kwe-weld kanye nokuqhekeka okumile | |||

| 45 | Gwema ukwakheka komugqa we-weld | |||

| welding radio-frequency | Weld ikhoyili ngendlela yesilinda ngokuqinile | 46 | Ukuhlolwa kwekhwalithi yokushisela | Gwema ukufakwa kwe-slag |

| 47 | Ukuze ugweme imifantu ngaphandle kwe-weld | |||

| 48 | Gwema ukuncipha kwezimpande | |||

| 49 | Gwema ukungena kwezimpande | |||

| 50 | Gwema ukwehluleka ukuhlanganisa | |||

| 51 | Gwema ukuvuza ukushisela, ukushisela okungamanga, ukushisela emathangeni nezinye izenzakalo. (Ngokuvamile, lapho ikhoyili idlula kurola eliqinisayo, unqenqema lwekhoyili luzoncibilika ngenxa yokushisisa kwamafrikhwensi aphezulu. Kuyoba khona i-milky crystal granular spark ngesikhathi sokushisela, okubonisa ukuthi ikhwalithi yokushisela iqinisekisiwe.) | |||

| Weld scraping isibazi | Sika futhi ugaye ukuphakama okusele kwe-weld yangaphandle | 52 | ukuhlolwa kokubukeka | Vimbela ukwenzeka kwe-swiveling seam, umlomo okhululekile kanye nokuhlukaniswa kwe-welding joint; Akudingi ukubola kwe-weld futhi awekho ama-nodule weld nhlangothi zombili. |

| 53 | Ukuhlolwa kwe-weld | Qinisekisa ukuthi imihuzuko yokushisela, umbala kanye nekhwalithi yokubumba ihlangabezana nezidingo ze-GB/ T13793-2008 (P10) | ||

| ukupholisa okujikelezayo | Ukupholisa ipayipi elishiselwe | 54 | Hlola umthamo wamanzi ethangi | Ngokusho kobubanzi bepayipi obuhlukene, isivinini, ukulawula izinga lamanzi, izinga lokushisa kwamanzi, ukugeleza kwamanzi, okuqukethwe kukasawoti, i-pH, njll |

| Ukulinganisa kweshubhu lensimbi | Lungisa ububanzi obungaphandle kanye nokungajikelezi kwepayipi elishiselwe | 55 | Ukuhlolwa kobubanzi bangaphandle | Ukulawula ku-GB/T21835 -- izimfuneko ezijwayelekile ze-2008 (P5) phakathi kwebanga |

| 56 | Ukuhlola ukungazungezile | Ukulawula kuzidingo ezijwayelekile ze-GB/ T3091-2015 (P4) ngaphakathi kobubanzi | ||

| Ukuqondisa okungalungile | Susa ukugoba okuncane kweshubhu lensimbi | 57 | Bheka imishini yokuqondanisa | Sebenzisa idivayisi yokuqondisa ukwenza ipayipi lensimbi liqonde enqubweni elandelayo |

| I-NDT(ukuhlola okungabhubhisi) | Hlola ukukhubazeka okungaphezulu nangaphakathi kwe-weld okungase kuthinte ikhwalithi yepayipi lensimbi | 58 | Lungisa ithuluzi ngaphambi kokuhlola | Setha imingcele efanele; Nquma ingxenye yokuskena kanye nokuzwela kokutholwa kwamaphutha ngebhulokhi yokuhlola yokuqhathanisa; Khulisa isinxephezelo esingaphezulu ukuze uqinisekise izinga lokutholwa kokukhubazeka |

| 59 | Ukuhlolwa kwenqwaba yokuqala ngemva kokucaciswa kokushintshwa | Ngemuva kokushintshwa ngakunye kokucaciswa komkhiqizo, iqoqo lokuqala lemikhiqizo eqediwe kufanele lihlolwe. Inani lamagatsha okuhlola akufanele libe ngaphansi kwamathathu. Ngemva kokudlula ukuhlolwa, umkhiqizo ungakhiqizwa | ||

| 60 | Ukuhlolwa kwensimbi eyisisekelo yamapayipi ashiselwe | Ukuhlolwa okubonakalayo kokushiyeka kwekhwalithi ye-steel surface surface | ||

| 61 | Ukuhlolwa kokubukeka kwe-weld | Ngokuhlola okubonakalayo kokubukeka kwe-weld ngemva kokupholisa, akukho sici esifana nokuchithwa kwe-weld, ukushiswa, izibazi, ukuvuleka, ukuqhekeka, ukuqhekeka kwe-tendon, ukukhuhla isibazi esingalingani, umlomo okhululekile uvunyelwe. | ||

| 62 | Ukuhlolwa kwe-Ultrasonic kwensimbi nokushisela ikhwalithi yangaphakathi yeSpot kanye nempendulo | I-probe enamathiselwe emzimbeni weshubhu ikhipha igagasi le-ultrasonic, futhi insimbi ithola futhi ihlaziye i-echo ebonisiwe. Ukuzwela kwesithenjwa sokuthola kulungiswa ngokuya nge-SY/ T6423.2-1999, futhi uhlobo, usayizi nokujula kwesibonisi kunqunywa ukuphakama kwe-echo wave okuboniswa esikrinini sethuluzi. Akuvunyelwe ukuba nanoma yikuphi ukukhubazeka okuthinta kakhulu ikhwalithi ye-weld, njengokuqhekeka, izimbotshana ukuphakama kwazo kwe-echo wave kudlula u-50% wesikrini esigcwele, ukungangeni nokungahlanganisi.Imithetho yokuhlola isampula: ukuhlolwa kwesampula kuzokwenziwa ngokuya ngo-1% weqoqo ngalinye. Uma kukhona inkinga etholakele, rekhoda futhi unikeze impendulo kusenesikhathi. Yenza amamaki asobala kumaphutha ukusiza abasebenzi ukuthi babhekane nokuhambisanayo; Khulisa izinga lamasampula ngo-10%. Uma kusenemikhiqizo engafanelekile ohlelweni lokuhlola amasampula, iyunithi kufanele yaziswe ukuthi ime futhi ilungise inqubo yokukhiqiza ngesikhathi. | ||

| I-Flying saw cutting | Ukusetha ukusika kwepayipi elishiselwe izinqe | 63 | Ukuhlolwa kwamapayipi | Ukuphela kwepayipi kuzoqinisekiswa ngaphandle kwe-burr nomlomo othambekele |

| 64 | ukusika ubude | Hlola i-diameter yerola yesivinini ngokwezinga bese usetha idatha ephusile | ||

| Ukuqondisa kweshubhu lensimbi | Lungisa ukugoba kweshubhu yensimbi | 65 | ukuhlolwa kokubukeka | Gwema ukulimala komzimba we-tube, i-tube mouth flattening isenzeko; Akukho ukuhlehlisa endaweni yeshubhu |

| Ipayipi lokugcina gcina | Ukubhekana ne-burr yomlomo wepayipi | 66 | Ukuhlolwa kwamapayipi | Qinisekisa ukuthi ukuphela kwepayipi kubushelelezi futhi ngaphandle kwe-burr, futhi uqinisekise ukuthi ipayipi lensimbi ngalinye lingakwazi ukufeza "umphumela wepayipi eliqondile". |

| ukuhlolwa komkhiqizo ophelile | Qinisekisa ukuthi ikhwalithi yepayipi elishiselwe endaweni yokusebenzela ihlangabezana nezidingo ezijwayelekile | 67 | ukuhlolwa kokubukeka | Qinisekisa ukuthi ubuso bepayipi lensimbi bushelelezi, akukho ukugoqa, ukuqhekeka, isikhumba esiphindwe kabili, i-lamination, i-lap welding kanye nezinye iziphambeko zikhona, vumela ukuba nobukhulu bodonga lokuchezuka okungalungile kohla lokuphambuka, ungavumeli ukuba nokuklwebheka okukhulu, ukuhlukaniswa kwe-weld, ukushisa kanye nesibazi. |

| 68 | Ukuhlolwa kwe-weld yangaphakathi | Qinisekisa ukuthi ibha yokushisela iqinile, ukujiya okufanayo, esimweni socingo, ibha yokushisela yangaphakathi kufanele ibe ngaphezu kuka-0.5mm, ibha yokushisela yokufaka ipayipi ayivunyelwe ukuba ne-burr | ||

| 69 | Ukuhlolwa kobubanzi bangaphandle | Ukulawula ku-GB/T21835 -- izimfuneko ezijwayelekile ze-2008 (P5) phakathi kwebanga | ||

| 70 | Ukuhlola ukungazungezile | Ukulawula kuzidingo ezijwayelekile ze-GB/ T3091-2015 (P4) ngaphakathi kobubanzi | ||

| 71 | Ukulinganisa ubude | Ubude bepayipi lensimbi buyi-6m. Ngokwezidingo ze-GB/ T3091-2015, ukuchezuka okuvumelekile kobude obuphelele bomphetho oqondile wepayipi elishiselwe imvamisa ephezulu ngu-+20mm. (izidingo zamapayipi: amaminithi angu-4 - 2 amayintshi 0-5mm, 2.5 amayintshi - 4 amayintshi 0-10mm, 5 amayintshi - 8 amayintshi 0-15mm) | ||

| 72 | Ukutholwa kwegoba | Ngokusho kwe-GB/ T3091-2015, izinga lokugoba lobude obugcwele bepayipi lensimbi akufanele libe likhulu kuno-0.2% wobude bepayipi lensimbi. | ||

| 73 | Ukuhlolwa kwamapayipi | Qinisekisa ukuthi ikhanda lepayipi alinayo i-burr futhi ingxenye yokugcina ihlangabezana nezidingo ze-GB/ T3091-2015 | ||

| 74 | Ukuhlolwa kwe-weld yangaphandle | I-weld weld scaring yangaphandle kufanele isebenzise ummese we-arc, isibazi sokukhuhla kufanele sibe yi-arc transition. | ||

| 75 | Ama-Gouges lapho izingcezu zonke bezingekho khona | Gwema ukuvula ekugcineni kwepayipi | ||

| 76 | Ukutholwa komfantu | Gwema ukuqhekeka kubha yokushisela | ||

| 77 | Ukuhlola ngokuhlanganyela | Gwema into ehlangene emzimbeni wepayipi oshiselwe | ||

| 78 | Sika ukuze uhlole | Gwema imihuzuko engathi sína ebusweni bepayipi elishiselwe, elizothinta ukushuba kodonga. Ukuchezuka okungekuhle kungabi ngaphansi kogqinsi lodonga (12.5%) | ||

| 79 | Ifulethi lokuhlola umgodi | Vimbela imigodi nemigodi ebangelwa amandla angaphandle epayipi elishiselwe. Izinga lokulawulwa kwangaphakathi kwebhizinisi (imizuzu emi-4 - iyintshi engu-1, ukujula komgodi <2mm; 1¼ intshi-2 intshi, ukujula komgodi <3mm; 2½ amayintshi-6 amayintshi, ukujula komgodi <4mm; 8 amayintshi ukujula <6mm) | ||

| 80 | Ukuhlolwa kwe-pitting surface (umgodi) | Gwema ama-punctate dents ebusweni be-steel tube | ||

| 81 | Hlola ibha yokushisela yangaphakathi | Vimbela ibha yokushisela ayiqinile, ayilingani, ngaphansi kuka-0.5mm ngoba ibha yokushisela ayifanelekile | ||

| 82 | Ukuhlolwa kwe-Burr | Gwema izingxenye ezingaphezulu ezingavamile ngaphakathi nangaphandle kwekhanda lepayipi. Izinga lokulawula kwangaphakathi kwebhizinisi (amaphoyinti angu-4 - amayintshi angu-2 we-burr <1mm; 2½ intshi ukuya ku-4 intshi burr <2mm; 5 "- 8" burr <3mm. Qaphela: I-Burr ayivunyelwe kupayipi lekhanda lenetha. | ||

| 83 | Ukuhlola umlomo olengayo | Gwema ukuvuleka noma ukuguqulwa okubangelwa ihuku noma ukuphakamisa, okungukuthi "umlomo ophakamisayo" | ||

| 84 | Ukuhlolwa kokuqhekeka kokuqinisa | Vimbela ukuqhekeka okuncane kobuhlalu obushiselayo | ||

| 85 | Isibazi sokukhuhla singalingani | Gwema ibha yokushisela engalingani ngemva kokukhuhla isibazi. Ibha yokushisela ayiyona indawo ye-arc ebushelelezi. Umehluko omubi ophansi kunensimbi yesisekelo ubhekwa njengongalingani | ||

| 86 | Kusukela emlonyeni ukuhlola | Vimbela ukwenzeka kokugoqa kwe-welding seam kanye nengcindezi ebangelwa izinto ezingavuthiwe noma izizathu zemishini, ibha yokushisela ayibushelelezi, kunemiphetho yamahhala, ukugoqa kwe-weld dislocation, njll. | ||

| 87 | Ukuhlola isikhumba kabili | Gwema ingaphezulu alibushelelezi, linezingqimba, inyama encane noma into engalingani | ||

| 88 | Ukuhlola isibazi | Gwema izindawo zokudambisa ezingase zidale ukulimala kwesisekelo sensimbi | ||

| 89 | Imigodi yesihlabathi ukuhlola | Vimbela izimbobo ebusweni be-steel tube | ||

| 90 | Ukuhlola umlomo we-Oblique | Ingxenye ephambanayo yepayipi ayihambisani nomugqa ophakathi, futhi isiphetho sizohlangabezana nezidingo ze-GB/ T3091-2015. | ||

| 91 | Ukuhlolwa kobunikazi | Gwema uphawu lokuhweba olunamathele emzimbeni wepayipi futhi ukucaciswa kwangempela kwepayipi elishiselwe akuhambisani noma kuxubile. | ||

| ukuhlolwa komshini | Hlola izakhiwo zemishini yezinto | 92 | ukugoba ukuhlolwa | Hlola ikhwalithi yokushisela yamapayipi ensimbi angu-2 amayintshi nangaphansi ukuze uhlangabezane nezidingo ze-GB/ T3091-2015 (P7) |

| 93 | ukuhlolwa flattening | Ukuhlola izinga lokushisela lamapayipi ensimbi ngaphezu kwamayintshi angu-2 futhi uhlangabezane nezidingo ze-GB/ T3091-2015 (P7) | ||

| 94 | Ukuhlolwa kwethangi lokucindezela | Hlola ukusebenza komsele wokucindezela wepayipi lensimbi, ngokuhambisana ne-CECS 151-2003 izimfuneko zobunjiniyela zepayipi lokuxhumana lomsele (P9) | ||

| 95 | ukuhlolwa kwe-tensile | Hlola amandla aqinile nobude ngemva kokuphuka kwepayipi lensimbi ukuze uhlangabezane nezidingo ze-GB/ T3091-2015 (P7) | ||

| Ukuhlolwa komfutho wamanzi | Hlola amandla, ukungangeni komoya kanye nekhwalithi yokubukeka kwesisekelo sensimbi nokushisela kwepayipi elishiselwe | 96 | Hlola ngaphambi kokukhipha | Gwema ukungqubuzana phakathi kwelebula kanye nokucaciswa kwangempela kwepayipi elishiselwe noma iqoqo elixubile alivunyelwe ukuqaqa (inombolo yenqwaba efanayo kanye nokucaciswa okufanayo kucindezelwa ndawonye |

| 97 | ukuhlolwa okubonakalayo | Ukuhlolwa okubukwayo kwesisekelo sensimbi ukuvikela ukuqhekeka, isikhumba esinzima, ukugqwala okungathi sína, izimbobo zesihlabathi nokunye ukukhubazeka, ukuklwebheka okubi akuvunyelwe. | ||

| 97 | Hlola isiphetho ngaphambi kokuqala ukuhlolwa | Ingaphezulu lazo zombili iziphetho zepayipi elishiselwe kufanele libe bushelelezi futhi libushelelezi ngokuhlola okubonakalayo. Akuvunyelwe ukuba nekhanda eliyisicaba, ipayipi eligobile kanye nomlomo olengayo. Ingxenye yokuphela kwepayipi elingenayo i-burr i-perpendicular emgqeni ophakathi. Ayikho indiza ethambekele futhi ukuchezuka kufanele kube ngaphansi kuka-3° | ||

| 98 | Hlola indlela yokudlulisa ingcindezi (amanzi) ngaphambi kokucindezela | Ngemva kokugcwalisa umshini wokudlulisa ukucindezela (amanzi) wepayipi elishiselwe, ungasheshi ukwandisa ukucindezela. Kuyadingeka ukuhlola ukuthi uhlelo lunokuvuza kwe-liquid | ||

| 99 | ukuhlolwa kwe-hydrostatic | Ngokusho kwe-GB/ T241-2007 standard (P2) ngaphansi kwengcindezi yokuhlola, isivinini sokucindezela kanye nezimo ezimaphakathi zokudlulisa ingcindezi, ezinzile isikhathi esithile. Bheka ngokubonakalayo indawo engaphandle ye-weld tube matrix noma i-weld seam phakathi nesikhathi sokuqiniswa kwengcindezi. Akukho ukuvuza noma ukuqhuma okuvunyelwe. Hlola ngokubuka ipayipi lonke elishiselwe ngemva kokuhlolwa, akukho deformation unomphela evunyelwe | ||

| 100 | Ukuhlolwa kokubukeka ngemva kokuhlolwa | Qinisekisa ukuthi akukho ukuklwebheka okuvunyelwe; Ikhanda eliyisicaba kanye nepayipi eligobile akuvunyelwe. Akukho ukungcoliswa kwamafutha nezinye izinkinga zekhwalithi ngaphakathi nangaphandle kwepayipi lensimbi | ||

| 101 | Umbiko okhishwe ngu | Gcwalisa ngokuhambisana ngokuqinile nezinga le-GB/ T241-2007 (P2) kanye nezibonelo ezikhethekile zangaphakathi (zithunyelwe ngokuphindwe kathathu emnyangweni wokukhiqiza, umnyango wokuhlola ikhwalithi, nepayipi lensimbi elicosha ikhophi eyodwa). Abukho ukukhwabanisa okuvunyelwe | ||

| Pickling test | Yehlisa ukulawulwa kwekhwalithi okunephutha kunqubo elandelayo | 102 | Ukuhlolwa kokuhlonza | Qinisekisa ukujiya kodonga lwangempela, ukucaciswa noma ukuxutshwa kwelebula nepayipi elishiselwe ngokulinganisa nokukala |

| 103 | Ukuhlolwa kokungazungezile | Qinisekisa ukuthi ukungazungezile kwepayipi lensimbi kuhambisana nezinga likazwelonke le-GB/T 3091-2015 (P4) | ||

| 104 | Ukuhlola ubude bokulinganisa | Qinisekisa ubude bepayipi lensimbi ngokuhambisana nezinga likazwelonke le-GB/T 3091-2015 (P5) (amamitha angu-6, ukuchezuka okuvumelekile +20mm) | ||

| 105 | Ukuhlolwa kobubanzi bangaphandle | Qinisekisa ukuthi ububanzi bangaphandle bepayipi lensimbi buhlangabezana nezidingo ze-GB/T21835 -- 2008 Standard (P5) | ||

| 106 | Vula ukuhlola | Hlola ukuthi isiphetho sepayipi sinomkhuba osikiwe yini | ||

| 107 | Ukuhlolwa kokuphuka | Ngemuva kokushaqeka kwesando, akukho mkhuba wokuqhekeka kubha yokushisela | ||

| 108 | Ukuhlola ngokuhlanganyela | Buka ishubhu efanayo ukuthi ikhona yini into yokudokha | ||

| 109 | Inhlolovo yamapayipi agqwalile | Bheka ngokubukeka ukuthi akukho yini ukungcola, upende, amabala kawoyela namapayipi agqwalile ebusweni bepayipi lensimbi | ||

| 110 | Ukuhlolwa komgodi oyisicaba | Bheka ngokubukeka ukuthi ingabe ingaphezulu lepayipi lensimbi linemigodi yendawo ebangelwa amandla angaphandle | ||

| 111 | Ukuhlolwa kwe-pitting surface (imigodi) | Usebenzisa ukuhlola okubonakalayo, thinta ngesandla ingaphezulu lepayipi lensimbi noma ngabe likhona iphuzu le-bump phenomenon | ||

| 112 | Hlola ukuthi ibha yokushisela yangaphakathi ifanelekile yini | Ukuvimbela ukuba khona kwe-welding bar yangaphakathi (kuhlanganise ne-welding yamanga) noma ibha ye-welding yangaphakathi idlule izinga kanye nezinye izinkinga; Ukuvimbela ibha yokushisela ayiqinile, ayilingani, noma ngaphansi kuka-0.5mm ayifanelekile | ||

| 113 | Ukuhlolwa kwe-Burr | Hlola ngokubuka ukuthi azikho yini izingxenye ezeqile ezingajwayelekile ngaphakathi nangaphandle kwesiphetho seshubhu. Ngemuva kokwelashwa, i-burr yokuphela kwepayipi kufanele ibe ngaphansi kuka-0.5mm ukuze ifaneleke | ||

| 114 | Ukuhlolwa komlomo olengayo | Ukuvimbela ukuvulwa noma ukuguqulwa okubangelwa ku-hook kanye nenqubo yokuphakamisa | ||

| 115 | Ukuhlolwa kokuqhekeka kokuqinisa | Ngokugoba noma ukuhlolwa kokucaba, ibha yokushisela yepayipi yensimbi itholwa ukugwema ukuba khona kwemifantu emincane. Bheka ku-Athikili 8 ye-P6 Yokulawula Ikhwalithi Nohlelo Lokuphatha ukuze uthole ukuhlolwa kokugoba | ||

| 116 | Ukuhlolwa kwesibazi | Qinisekisa ukuthi i-welding bar ekhuhla isibazi ibushelelezi, eyindilinga | ||

| 117 | Ukuhlolwa kwechweba kwamahhala | Gwema ukwenzeka kokugoqa ingcindezi kumthungo wokushisela okubangelwa izinto ezingavuthiwe noma izizathu zemishini | ||

| 118 | Ukuhlolwa kwesikhumba okukabili | Gwema ukwenzeka kweshubhu lensimbi elinesikhumba esiphindwe kabili | ||

| 119 | Umbuthano omise okwe-bamboo | Ukuvimbela ubuso bepayipi lensimbi kusuka kuma-slubby dents | ||

| 120 | Ukuhlolwa kwe-lap weld | Ukuhlola okubonakalayo ukuze kugwenywe into eyenzeka yokushisela izinqe ezingafuneki kubha yokushisela yensimbi | ||

| 121 | Ukuhlolwa kwesibazi | Ukuhlola okubonakalayo ukugwema izindawo zokushisela ebusweni bepayipi lensimbi | ||

| 122 | Imigodi yesihlabathi, ukuhlola | Ukuhlola okubonakalayo ukugwema izimbobo ebusweni bepayipi lensimbi | ||

| 123 | Sika ukuhlolwa | Thola umzimba wepayipi ngaphansi kwezinto zokubopha igesi ukuze uqiniseke ukuthi akukho ukusika noma ukulimala | ||

| 124 | Akukho okufanelekile ukukha ama-sundries aphekiwe | Ukuhlolwa okubukwayo ukuze kuqinisekiswe ukuthi awekho amabala kawoyela, upende nokunye okungelula ukucwilisa imfucumfucu, ukuvikela ukuvuza kwe-plating. | ||

| Ipayipi lensimbi yokukhetha | Susa ama-sundries njengesikali se-oxide esikhiqizwe ebusweni bepayipi lensimbi | 125 | Ukuhlushwa kwe-asidi | Okuqukethwe kwe-hydrogen chloride ekugxilweni kwe-asidi kufanele kulawulwe ku-20% -24% |

| 126 | Ukuhlolwa kwe-underpickling yepayipi lensimbi | Ukuvimbela (1) isikhathi esinganele sokukhetha, izinga lokushisa eliphansi le-asidi, ukuhlushwa okuphansi (izinga lokushisa kufanele lilawulwe ku-25-40 ℃, ukuhlushwa kwe-asidi ye-hydrogen chloride ngu-20% -24%) (2) izikhathi ezingaphansi zokuzamazama ze-tube bundle (3) ukuba khona kwe-silicate esithandweni esishiselwe ishubhu lensimbi. | ||

| ukupakishwa komkhiqizo | Ipakishwe ngokuhambisana nenani elishiwo lamapayipi ensimbi ngocezu ngalunye | 127 | Ukuhlolwa kwebhande lokupakisha | Ukupakishwa kwepayipi lensimbi kune-hexagonal, amabhande okupakisha angu-6, konke kwenziwa embonini yethu, zombili iziphetho zebhande lokupakisha kusukela ekupheleni kwephutha lika-± 10mm, maphakathi ne-4 kufanele ihlukaniswe ngokulinganayo, ukupakisha ibhande lokupakisha kufanele kuhambisane, i-flat, ibhande lokupakisha alivumeli ukuphambuka, ibhande lokupakisha kufanele linqunywe ekuhlanganiseni kwe-45 ° |

| 128 | Ukuhlola uphawu lokuhweba | Okuqukethwe kunembile, indiza iphezulu, uphawu lokuhweba lwepayipi eliqediwe kufanele lunanyathiselwe kahle ku-baffle yepayipi ngalinye ukuze kuqondiswe ohlangothini lwesokudla lwebhande lokuqala lokupakisha lokushisela phakathi nendawo, futhi umthombo u-Ted ohlobisa umbhalo ucacile futhi awukhohlisi. |