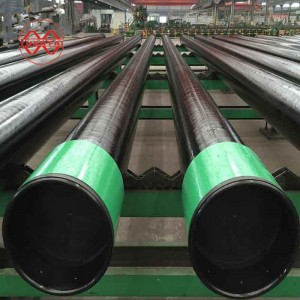

A cewar American Petroleum Institute Standard API SPEC 5CT1988 1st edition, da karfe sa na API 5CT man casing bututu za a iya raba goma iri, ciki har da H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P-110 da Q-125. Muna ba da bututun casing & API 5CT K55 Casing Tubing tare da zaren da haɗin kai, ko kuma muna ba da samfuranmu daidai da waɗannan fom ɗin don zaɓi.

If you are interested in API 5CT K55 Casing Tubing, we will supply you with the best price based on the highest quality, welcome everyone to cantact us,E-mail:sales@ytdrgg.com,and Remote factory inspection or factory visit

API 5CT K55 Ƙayyadaddun Ƙirar Rubutun Casing

| API 5CT K55 BAYANIN CASING TUBING | ||

| Akwai Girman Girma | 2 3/8 ", 2 7/8" da 3 ½ " Diamita na waje | |

| Maki | J55, J55-FBNAU, N80, L80, P110 | |

| Tuba | 1 1/4 "- 2 1/16" Nam. | |

| Matsayi | API SPEC 5CT | |

| Samfura a Amfani da Jama'a | 2-3/8 ″, 2-7/8″, 3-1/2″, 4″, 4-1/2″ | |

| Tsawon Tsayin | R1 (6.10-7.32m), R2 (8.53-9.75m), R3 (11.58-12.8m) | |

| Matsayin Karfe (Makin Casing, Makin Tubing) | J55, K55, N80-1, N80-Q, L80, P110 | |

| Nau'in Zaren Screw | Ƙarshen zaren da ba na tashin hankali ba (NUE), Ƙarshen zaren ruɗi na waje (EUE) | |

| Musamman |

| |

| Ƙarshen Ƙarshe | Endet na waje ya ƙare (ue), flush hadin gwiwa, ph6 (kuma daidai alaka), hade da hadin gwiwa (ij) | |

API 5CT K55 Casing Tubing Tensile & Harness Bukatun

| Rukuni | Daraja | Nau'in | Jimlar tsawo ƙarƙashin kaya % | Samar da ƙarfi MPa | Ƙarfin ƙarfi min. MPa | Hardness a max. | Ƙayyadadden kauri na bango mm | Bambancin taurin da aka yarda b HRC | ||

|---|---|---|---|---|---|---|---|---|---|---|

| min. | max . | HRC | HBW | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 1 | H40 | - | 0.5 | 276 | 552 | 414 | - | - | - | - |

| J55 | - | 0.5 | 379 | 552 | 517 | - | - | - | - | |

| K55 | - | 0.5 | 379 | 552 | 655 | - | - | - | - | |

| N80 | 1 | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| N80 | Q | 0.5 | 552 | 758 | 689 | - | - | - | - | |

| R95 | - | 0.5 | 655 | 758 | 724 | - | - | - | - | |

| 2 | M65 | - | 0.5 | 448 | 586 | 586 | 22 | 235 | - | - |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| L80 | 13 Cr | 0.5 | 552 | 655 | 655 | 23 | 241 | - | - | |

| C90 | 1 | 0.5 | 621 | 724 | 689 | 25.4 | 255 | ≤ 12.70 12.71 zuwa 19.04 19.05 zuwa 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| T95 | 1 | 0.5 | 655 | 758 | 724 | 25.4 | 255 | ≤ 12.70 12.71 zuwa 19.04 19.05 zuwa 25.39 ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| C110 | - | 0.7 | 758 | 828 | 793 | 30 | 286 | ≤ 12.70 12.71 zuwa 19.04 19.05 zuwa 25.39. ≥ 25.40 | 3.0 4.0 5.0 6.0 | |

| 3 | P110 | - | 0.6 | 758 | 965 | 862 | - | - | - | - |

| 4 | Q125 | 1 | 0.65 | 862 | 1034 | 931 | b | - | ≤ 12.70 12.71 zuwa 19.04 ≥ 19.05 | 3.0 4.0 5.0 |

| aIdan akwai jayayya, gwajin taurin Rockwell C na dakin gwaje-gwaje za a yi amfani da shi azaman hanyar alkalin wasa. bBa a kayyade iyakokin taurin ba, amma matsakaicin bambancin yana iyakance daidai da 7.8 da 7.9 na API Spec. 5CT. | ||||||||||

K55 Matsakaicin Tubin Casing

| Girman Cajin Bututu, Girman Rubutun Filin Mai & Girman Rubutun Casing | |

|---|---|

| Diamita Na Waje (Mai Girman Bututun Casing) | 4 1/2 "-20", (114.3-508mm) |

| Daidaitaccen Girman Casing | 4 1/2 "-20", (114.3-508mm) |

| Nau'in Zare | Tushen zaren gindi, Dogon zaren zare, Shortan zaren casing |

| Aiki | Zai iya kare bututun tubing. |

Bututun Mai Na Man Fetur Da Masana'antar Gas

| Sunan Bututu | Ƙayyadaddun bayanai | Karfe daraja | Daidaitawa | ||

|---|---|---|---|---|---|

| D | (S) | (L) | |||

| (mm) | (mm) | (m) | |||

| Bututun Casing Petroleum | 127-508 | 5.21-16.66 | 6-12 | J55. M55.K55. L80. N80. P110. | API Spec 5CT (8) |

| Tushen mai | 26.7-114.3 | 2.87-16.00 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

| Haɗin kai | 127-533.4 | 12.5-15 | 6-12 | J55. M55. K55. L80. N80. P110. | API Spec 5CT (8) |

API 5CT K55 Siffofin Rubutun Casing

- API 5CT K55 Casing Tubing ana ba da shi tare da kewayon tsayi kyauta daga 8m zuwa 13m bisa ƙa'idar SY/T6194-96. Duk da haka, shi ma yana samuwa ba kasa da 6m tsawon kuma yawansa kada ya wuce 20%.

- Nakasar da aka ambata a sama ba a yarda su bayyana a saman saman API 5CT K55 Casing Tubing coupling.

- Duk wani nakasar kamar layin gashi, rabuwa, ƙugiya, tsagewa ko scab ba a yarda da shi a ciki da waje na samfurin. Duk waɗannan lahani yakamata a cire su gaba ɗaya kuma zurfin da aka cire dole ne ya wuce 12.5% na kauri na bango.

- Filayen zaren haɗin gwiwa da API 5CT K55 Casing Tubing ya kamata ya zama santsi ba tare da wani burbushi ba, tsagewa ko wasu lahani waɗanda zasu iya yin mummunan tasiri akan ƙarfi da haɗin gwiwa.

Yana da mahimmanci ga ma'aikatan mai da iskar gas don kare samar da rijiyoyin samar da su daga lalata tare da kariya ta cathodic & API 5CT OilField Tubing da farko yana ba da gudummawar mai da iskar gas.

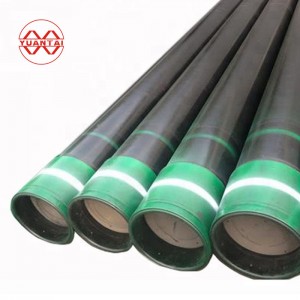

API 5CT Grade K55 Casing Tubing Karfe Launi

| Suna | J55 | K55 | N80-1 | N80-Q | L80-1 | P110 |

|---|---|---|---|---|---|---|

| Casing | band mai haske kore | biyu masu haske kore makada | band ja mai haske | band mai haske mai haske + koren band | band ja + launin ruwan kasa | band mai haske mai haske |

| Haɗin kai | duka koren hada hada guda biyu + farar band | duka kore hada guda biyu | gaba dayan jajayen hada biyu | gabaɗayan haɗin haɗin jajayen + koren band | gabaɗayan haɗin haɗin jajayen + band mai launin ruwan kasa | gaba daya farar hada biyu |

ISO/API casing/ API 5CT K55 Caka dalla-dalla

| Codea | Dia na waje | Nauyin mara kyau (tare da zaren haduwa) b,c | Kaurin bango | Nau'in sarrafawa na ƙarshe | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N801 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | N80Q | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1-2 | 9.5 | 114.3 | 14.14 | 5.21 | S | S | S | - | - | - | - | - |

| 4-1-2 | 10.5 | 114.3 | 15.63 | 5.69 | - | SB | SB | - | - | - | - | - |

| 4-1-2 | 11.6 | 114.3 | 17.26 | 6.35 | - | SLB | - | LB | LB | - | LB | - |

| 4-1-2 | 13.5 | 114.3 | 20.09 | 7.37 | - | - | LB | - | LB | - | - | - |

| 4-1-2 | 15.1 | 114.3 | 22.47 | 8.56 | - | - | - | - | - | - | LB | LB |

| 5 | 11.5 | 127 | 17.11 | 5.59 | - | S | S | - | - | - | - | - |

| 5 | 13 | 127 | 19.35 | 6.43 | - | SLB | SLB | - | - | - | - | - |

| 5 | 15 | 127 | 22.32 | 7.52 | - | SLB | LB | - | - | - | LB | - |

| 5 | 18 | 127 | 26.79 | 9.19 | - | - | LB | - | LB | - | - | LB |

| 5 | 21.4 | 127 | 31.85 | 11.1 | - | - | LB | - | LB | - | - | LB |

| 5 | 23.2 | 127 | 34.53 | 12.14 | - | - | - | LB | - | - | - | LB |

| 5 | 24.1 | 127 | 35.86 | 12.7 | - | - | - | LB | - | - | - | LB |

| 5-1-2 | 14 | 139.7 | 20.83 | 6.2 | S | S | S | - | - | - | - | - |

| 5-1-2 | 15.5 | 139.7 | 23.07 | 6.98 | - | SLB | SLB | - | - | - | - | - |

| 5-1-2 | 17 | 139.7 | 25.3 | 7.72 | - | SLB | LB | - | - | LB | - | - |

| 5-1-2 | 20 | 139.7 | 29.76 | 9.17 | - | - | LB | - | LB | - | - | - |

| 5-1-2 | 23 | 139.7 | 34.23 | 10.54 | - | - | - | LB | - | LB | - | - |

| 6-5-8 | 20 | 168.28 | 29.76 | 7.32 | S | SLB | SLB | - | - | - | - | - |

| 6-5-8 | 24 | 168.28 | 35.72 | 8.94 | - | SLB | LB | - | - | LB | - | - |

| 6-5-8 | 28 | 168.28 | 41.67 | 10.59 | - | - | - | - | LB | - | LB | - |

| 6-5-8 | 32 | 168.28 | 47.62 | 12.06 | - | - | - | LB | LB | |||

| 7 | 17 | 177.8 | 25.3 | 5.87 | S | - | - | - | - | - | - | - |

| 7 | 20 | 177.8 | 29.76 | 6.91 | S | S | S | - | - | - | - | - |

| 7 | 23 | 177.8 | 34.23 | 8.05 | - | SLB | LB | LB | - | - | ||

| 7 | 26 | 177.8 | 38.69 | 9.19 | - | SLB | LB | LB | - | |||

| 7 | 29 | 177.8 | 43.16 | 10.36 | - | - | LB | LB | - | |||

| 7 | 32 | 177.8 | 47.62 | 11.51 | - | - | LB | LB | LB | - | ||

| 7 | 35 | 177.8 | 52.09 | 12.65 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 24 | 193.68 | 35.72 | 7.62 | S | - | - | - | - | - | - | - |

| 7-5-8 | 26.4 | 193.68 | 39.29 | 8.33 | - | SLB | LB | LB | - | |||

| 7-5-8 | 29.7 | 193.68 | 44.2 | 9.52 | - | - | LB | LB | - | |||

| 7-5-8 | 33.7 | 193.68 | 50.15 | 10.92 | - | - | LB | LB | - | |||

| 7-5-8 | 39 | 193.68 | 58.04 | 12.7 | - | - | - | LB | LB | |||

| 7-5-8 | 42.8 | 193.68 | 63.69 | 14.27 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 45.3 | 193.68 | 67.41 | 15.11 | - | - | - | LB | LB | LB | ||

| 7-5-8 | 47.1 | 193.68 | 70.09 | 15.88 | - | - | - | LB | LB | LB | ||

| 8-5-8 | 24 | 219.08 | 35.72 | 6.71 | - | S | S | - | - | - | - | - |

| 8-5-8 | 28 | 219.08 | 41.67 | 7.72 | S | - | S | - | - | - | - | - |

| 8-5-8 | 32 | 219.08 | 47.62 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 8-5-8 | 36 | 219.08 | 53.57 | 10.16 | - | SLB | SLB | LB | LB | - | ||

| 8-5-8 | 40 | 219.08 | 59.53 | 11.43 | - | - | LB | LB | - | |||

| 8-5-8 | 44 | 219.08 | 65.48 | 12.7 | - | - | - | LB | LB | |||

| 8-5-8 | 49 | 219.08 | 72.92 | 14.15 | - | - | - | LB | LB | LB | ||

| API 5CT Casing bututu Codea | API 5CT Casing bututu Outer diamita | API 5CT Bututun Casing Nauyin mara kyau (da zare da haɗin gwiwa) b,c | API 5CT Casing bututu Kaurin bango | API 5CT Casing bututu Nau'in sarrafa ƙarshen | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | kg/m | mm | H40 | J55 | M65 | L80 | N80 | C90d | P110 | Q125d | ||

| In | Lb/ft | K55 | C95 | 1, ku | T95d | |||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 9-5-8 | 32.3 | 244.48 | 48.07 | 7.92 | S | - | - | - | - | - | - | - |

| 9-5-8 | 36 | 244.48 | 53.57 | 8.94 | S | SLB | SLB | - | - | - | - | - |

| 9-5-8 | 40 | 244.48 | 59.53 | 10.03 | - | SLB | SLB | LB | LB | LB | - | - |

| 9-5-8 | 43.5 | 244.48 | 64.73 | 11.05 | - | - | LB | LB | LB | LB | LB | - |

| 9-5-8 | 47 | 244.48 | 69.94 | 11.99 | - | - | LB | LB | LB | LB | LB | LB |

| 9-5-8 | 53.5 | 244.48 | 79.62 | 13.84 | - | - | - | LB | LB | LB | LB | LB |

| 9-5-8 | 58.4 | 244.48 | 86.91 | 15.11 | - | - | - | LB | LB | LB | LB | LB |

| 10-3-4 | 32.75 | 273.05 | 48.74 | 7.09 | S | - | - | - | - | - | - | - |

| 10-3-4 | 40.5 | 273.05 | 60.27 | 8.89 | S | SB | SB | - | - | - | - | - |

| 10-3-4 | 45.5 | 273.05 | 67.71 | 10.16 | - | SB | SB | - | - | - | - | - |

| 10-3-4 | 51 | 273.05 | 75.9 | 11.43 | - | SB | SB | SB | SB | SB | SB | - |

| 10-3-4 | 55.5 | 273.05 | 82.59 | 12.57 | - | - | SB | SB | SB | SB | SB | - |

| 10-3-4 | 60.7 | 273.05 | 90.33 | 13.84 | - | - | - | - | - | SB | SB | SB |

| 10-3-4 | 65.7 | 273.05 | 97.77 | 15.11 | - | - | - | - | - | SB | SB | SB |

| 11-3-4 | 42 | 298.45 | 62.5 | 8.46 | S | - | - | - | - | - | - | - |

| 11-3-4 | 47 | 298.45 | 69.94 | 9.53 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 54 | 298.45 | 80.36 | 11.05 | - | SB | SB | - | - | - | - | - |

| 11-3-4 | 60 | 298.45 | 89.29 | 12.42 | - | SB | SB | SB | SB | SB | SB | SB |

| 13-3-8 | 48 | 339.72 | 71.43 | 8.38 | S | - | - | - | - | - | - | - |

| 13-3-8 | 54.5 | 339.72 | 81.1 | 9.65 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 61 | 339.72 | 90.78 | 10.92 | - | SB | SB | - | - | - | - | - |

| 13-3-8 | 68 | 339.72 | 101.19 | 12.19 | - | SB | SB | SB | SB | SB | SB | - |

| 13-3-8 | 72 | 339.72 | 107.15 | 13.06 | - | - | - | SB | SB | SB | SB | SB |

| 16 | 65 | 406.4 | 96.73 | 9.53 | S | - | - | - | - | - | - | - |

| 16 | 75 | 406.4 | 111.61 | 11.13 | - | SB | SB | - | - | - | - | - |

| 16 | 84 | 406.4 | 125.01 | 12.57 | - | SB | SB | - | - | - | - | - |

| 18-5-8 | 87.5 | 473.08 | 130.21 | 11.05 | S | SB | SB | - | - | - | - | - |

| 20 | 94 | 508 | 139.89 | 11.13 | SL | SLB | SLB | - | - | - | - | - |

| 20 | 106.5 | 508 | 158.49 | 12.7 | - | SLB | SLB | - | - | - | - | - |

| 20 | 133 | 508 | 197.93 | 16.13 | - | SLB | - | - | - | - | - | - |

| S-Short zaren zagaye, L-Dogon zaren zagaye, zaren B-Buttress | ||||||||||||

| a. Ana amfani da lambar don yin oda. | ||||||||||||

| b. Ana nuna ma'auni na ƙididdiga na zaren da aka haɗa da casing (shafi na 2) don tunani kawai. | ||||||||||||

| c. Martensitic chromium karfe (L80 9Cr da 13Cr) ya bambanta da carbon karfe a yawa. Nauyin da aka nuna na martensitic chromium karfe ba daidai bane kima. Ana iya amfani da ma'aunin gyaran ɗimbin yawa 0.989. | ||||||||||||

| d. C90, T95 da Q125 karfe sa casing ya kamata a kawota bisa ga ƙayyadaddun, nauyi da kauri bango da aka jera a sama ko tsari. | ||||||||||||

API 5CT K55 Haɗin Sinadari

| Rukuni | Daraja | Nau'in | C | Mn | Mo | Cr | Ni max. | Ku max. | P max. | S max. | Si max. | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| min. | max. | min. | max. | min. | max. | min. | max. | ||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1 | H40 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| J55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| K55 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | 1 | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| N80 | Q | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - | |

| R95 | - | - | 0.45c ku | - | 1.9 | - | - | - | - | - | - | 0.03 | 0.03 | 0.45 | |

| 2 | M65 | - | - | - | - | - | - | - | - | - | - | - | 0.03 | 0.03 | - |

| L80 | 1 | - | 0,43 a | - | 1.9 | - | - | - | - | 0.25 | 0.35 | 0.03 | 0.03 | 0.45 | |

| L80 | 9Cr | - | 0.15 | 0.3 | 0.6 | 0.9 | 1.1 | 8 | 10 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| L80 | 13 Cr | 0.15 | 0.22 | 0.25 | 1 | - | - | 12 | 14 | 0.5 | 0.25 | 0.02 | 0.01 | 1 | |

| C90 | 1 | - | 0.35 | - | 1.2 | 0,25 b | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| T95 | 1 | - | 0.35 | - | 1.2 | 0.25 d | 0.85 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| C110 | - | - | 0.35 | - | 1.2 | 0.25 | 1 | 0.4 | 1.5 | 0.99 | - | 0.02 | 0.005 | - | |

| 3 | P110 | e | - | - | - | - | - | - | - | - | - | - | 0,030 e | 0,030 e | - |

| 4 | Q125 | 1 | - | 0.35 | 1.35 | - | 0.85 | - | 1.5 | 0.99 | - | 0.02 | 0.01 | - | |

| Ana iya ƙara abun ciki na carbon don L80 zuwa 0.50 % matsakaicin idan samfurin ya ƙare. b Abubuwan da ke cikin molybdenum don Grade C90 Nau'in 1 ba shi da ƙaramin haƙuri idan kaurin bangon bai wuce 17.78 mm ba. c Ana iya ƙara abun ciki na carbon don R95 har zuwa 0.55 % matsakaicin idan samfurin ya ƙare. d Abubuwan da ke cikin molybdenum na T95 Nau'in 1 na iya raguwa zuwa 0.15 % ƙarami idan kaurin bangon bai wuce 17.78 mm ba. e Domin EW Grade P110, abun ciki na phosphorus zai zama matsakaicin 0.020 % da sulfur abun ciki 0.010 % matsakaicin. NL = babu iyaka. Za a ba da rahoton abubuwan da aka nuna a cikin nazarin samfur. | |||||||||||||||

API 5CT k55 Gr. Kayayyakin Injini

| API 5CT Casing Standard | Nau'in | API 5CT Ƙarfin Tensile Casing MPa | API 5CT Ƙarfin Ƙarfin Ƙarfin Casing MPa | API 5CT Hardness Casing Max. |

|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379 ~ 552 | -- |

| K55 | ≥517 | ≥ 655 | - | |

| N80 | ≥689 | 552 ~ 758 | - | |

| L80(13Cr) | ≥ 655 | 552 ~ 655 | Saukewa: 241HB | |

| P110 | ≥862 | 758 ~ 965 | -- |

Tare da fitarwa na shekara-shekara na ton miliyan 5, Yuantai Derun shine mafi girman bututun murabba'in ERW, bututun rectangular, bututu mara kyau, bututun galvanized da kuma masana'antar welded mai karkace a China. Kasuwancin shekara ya kai dala biliyan 15. Yuantai Derun yana da layin samar da bututun ERW guda 59, layin samar da bututun galvanized guda 10 da layukan samar da bututu mai karkata 3. Square bututu 20 * 20 * 1mm zuwa 500 * 500 * 40MM, rectangular karfe bututu 20 * 30 * 1.2mm zuwa 400 * 600 * 40MM, karkace bututu Ø 219-1420mm za a iya sanya daga karfe maki daga Q (s) 195. gr.a-gr.d. Yuantai Derun na iya samar da bututu masu murabba'in murabba'i bisa ga ASTM A500, JIS g3466, en10219, din2240 da as1163. Yuantai Derun yana da mafi girman kayan bututu mai murabba'i rectangular a China, wanda zai iya biyan buƙatun siyayya kai tsaye na abokan ciniki.

Maraba da kowa don tuntuɓar Yuantai Derun, imel:sales@ytdrgg.com, da kuma Real lokaci dangane dubawa shuka ko factory ziyara!

| Samfura | Api 5L X42/X52/X60/X70 |

| Daidaitawa | ku 5l |

| Daraja | X42,X52,X60,X65,X70 |

| Dabaru | Sanyi-birgima |

| OD mm | 21.3mm2032mm |

| WT mm | 0.5mm-60mm |

| Tsawon | 5.8m/6m/11.8m/12m ko kamar yadda ake bukata |

| Surface | Baƙi Painting/Galvanized/Varnish/3LPE Coating/Bare |

| Wurin asali | China (Mainland) |

| Aikace-aikace | 1.Fluid Pipe |

| 2.Bututun Mai | |

| 3.Gas Bututu | |

| 4. Tumbun Tumbura | |

| 5.Tsarin bututu | |

| 6.Taki bututu da dai sauransu | |

| Shiryawa | Ƙarƙashin bututun inch 8 zai kasance cikin ɗaure. A sama zai zama girma. |

| Sharuɗɗan ciniki | FOB, CFR, CIF, CIP da dai sauransu |

| Lokacin Biyan Kuɗi | 1.30% TT gaba da ma'auni da aka biya bayan dubawa |

| 2.LC a gani | |

| Lokacin Bayarwa | 7-30 aiki kwanaki bayan samu gaba biya ko LC |

NUNA MA'AIKATAR MA'AIKI

Mata ba kasa da maza ba.

Dagewar dagewa ya samu zakara guda daya na rukuni

Lokaci na iya canza komai, amma lokaci bazai canza komai ba, misali, zuciya ta farko

Mutanen Yuantai suna fada a wurare daban-daban

NUNA HOTON AIKIN FARKO

GABATARWA TA KUNGIYAR KWASTOMER

isarwa da dabaru

Kamfanin yana ba da mahimmanci ga ingancin kayayyaki, yana ba da jari mai yawa don ƙaddamar da kayan aiki na zamani da ƙwararru, kuma yana fita gaba ɗaya don biyan bukatun abokan ciniki a gida da waje.

Ana iya raba abun ciki dalla-dalla zuwa: abun ciki na sinadarai, ƙarfin yawan amfanin ƙasa, ƙarfin ɗaure, tasirin tasiri, da sauransu

A lokaci guda kuma, kamfanin na iya aiwatar da gano aibi na kan layi da cirewa da sauran hanyoyin magance zafi gwargwadon bukatun abokin ciniki.

https://www.ytdrintl.com/

Imel:sales@ytdrgg.com

Tianjin YuantaiDerun Steel Tube Manufacturing Group Co., Ltd.kamfanin bututun karfe ne wanda aka tabbatar da shiEN/ASTM/ JISƙwararre a cikin samarwa da fitar da kowane nau'in bututu mai murabba'i mai murabba'i, bututu mai galvanized, bututun walda na ERW, bututu mai karkace, bututu mai walƙiya mai ruɗi, bututu madaidaiciya, bututu maras kyau, mai rufin ƙarfe mai launi, ƙirar ƙarfe mai ƙarfi da sauran samfuran ƙarfe.

Whatsapp:+8613682051821